Sandcrete blocks are precast composite masonry units made of cement, sand, and water and are moulded into various sizes. According to the British Standard (BS 6073: 1981 Part 1), a block is a heterogeneous building material with a unit that is larger in all dimensions than what is required for bricks, but no dimension should be larger than 650 mm or the height should be six times the thickness or greater than the length. When set in their normal aspect, sandcrete blocks are walling units whose dimensions exceed those of bricks (NIS 87: 2007).

However, it should be noted that in BS EN 771-3:2011 + A1:2005 (which replaced BS 6073:1981), the distinction between blocks and bricks has been removed, and replaced by ‘masonry units’. A masonry unit is defined as a preformed component intended for use in masonry construction. Furthermore, no standard dimensions have been provided. A manufacturer is expected to declare the dimensions of the masonry units in mm in terms of Length, Width, and Height. Therefore, the new standard serves as a performance standard, and not a recipe standard.

It has been reported by some researchers that sandcrete blocks are the major masonry units used in Nigeria’s construction industry, accounting for more than 90% of the country’s physical infrastructure. As a result, sandcrete blocks are important components in building construction. They are commonly utilised as load-bearing and non-load-bearing walling units in Nigeria, Ghana, and other African nations.

Sandcrete blocks are reasonably priced when compared to other building materials. They offer great damage resistance without the additional cost of protective equipment. Unlike other building materials, sandcrete bricks don’t rust, rot, or serve as a haven for pests that cause harm. Furthermore, they don’t contain any environmentally hazardous substances. According to the Nigeria Industrial Standard (NIS 87: 2007), sandcrete blocks must have a minimum compressive strength of 2.5 and 3.45 N/mm2 for non-load bearing and load bearing walls, respectively.

Specifications for Sandcrete Blocks

The most popular sizes for sandcrete blocks are 450mm x 225mm x 225mm and 450mm x 150mm x 225mm. Sandcrete blocks can also be rectangular and solid or hollow. The Nigerian Industrial Standards (NIS 87: 2007) defined two types of blocks:

- Type A load bearing blocks, and

- Type B non-load bearing blocks

They both have the option of being solid or hollow.

The approved sizes for sandcrete blocks specified by the NIS are presented in Table 1;

| Type | Work size (mm) Length x Height x Thickness | Web Thickness | Usage |

| Solid Block | 450 x 225 x 100 | – | For non-load bearing and partition walls |

| Hollow | 450 x 225 x 113 | 25 | For non-load bearing and partition walls |

| Hollow | 450 x 225 x 150 | 37.5 | For load bearing walls |

| Hollow | 450 x 225 x 225 | 50 | For load bearing walls |

Masonry units that have a core void area larger than 25% of the gross area are considered hollow blocks. Lightweight aggregate is used to make hollow sandcrete blocks, which can be utilised to build both load-bearing and non-load-bearing walls. Blocks with two cells are typically produced in Nigerian construction factories. Sandcrete hollow blocks have a void running through them from top to bottom that takes up around one-third of their volume, yet solid blocks are completely devoid of voids.

When hardened, sandcrete blocks often have significant compressive strengths, and these strengths typically increase with density. Sandcrete hollow blocks should have a minimum strength requirement of 2.5 N/mm2 for 150 mm and 3.45 N/mm2 for 225 mm, according to NIS 87:2007.

Mix Ratios for Sandcrete Blocks

Sandcrete blocks are frequently produced using cement-sand mixtures with a cement-to-sand ratio of 1:6, 1:7, 1:8, or 1:9 and coarse aggregates no larger than 10 mm (when required for concrete blocks). When properly cured, these combinations produce sandcrete blocks with a compressive strength that is significantly high enough to meet construction standards.

The typical compressive strength obtained for different mix ratios and water-cement ratio for 450 x 150 x 225 (6 inches block) are shown in Table 2;

| W/C | 1:10 (fc at 28 days N/mm2) | 1:8 (fc at 28 days N/mm2) | 1:6 (fc at 28 days N/mm2) | 1:4 (fc at 28 days N/mm2) |

| 0.3 | 2.40 | 4.08 | 5.40 | 6.10 |

| 0.4 | 3.00 | 4.39 | 5.58 | 6.23 |

| 0.5 | 3.80 | 4.47 | 6.85 | 7.60 |

| 0.6 | 3.60 | 4.24 | 6.41 | 7.00 |

| 0.7 | 3.20 | 4.21 | 5.81 | 6.54 |

Therefore, the optimum water-cement ratio for maximum compressive strength in sandcrete blocks is 0.5. The mix ratio recommended by the NIS for sandcrete blocks in Nigeria is 1:8. For a 225mm hollow sandcrete block produced with a mix ratio of 1:8, the 28 days compressive strength is expected to be a minimum of 3.5 N/mm2 under laboratory controlled conditions. For 150 mm hollow block, a minimum compressive strength of 2.77 N/mm2 should be expected after 28 days of curing.

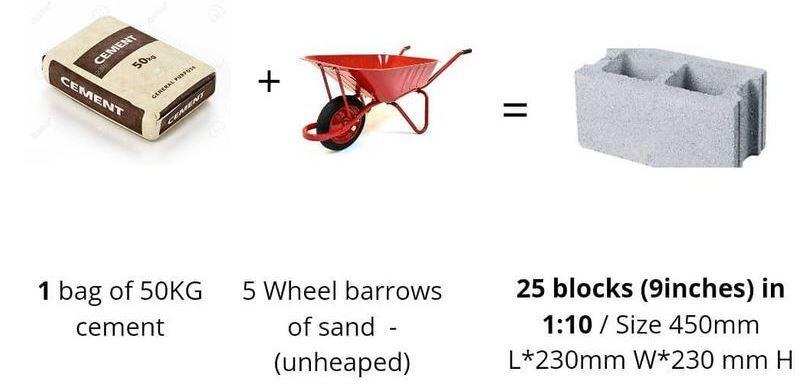

The following recommendations can be adopted in the production of 225 mm (9 inches) sandcrete blocks;

| Cement | Sand | Mix-Ratio | Expected Number of Blocks per bag (9 inches hollow) | Expected Minimum Compressive Strength (N/mm2) at 28 days using Manual Compaction |

| One bag | 3 wheelbarrows (12 head pans) | 1:6 | 15 | 5.6 |

| One bag | 3½ wheelbarrows (14 head pans) | 1:7 | 17 | 4.2 |

| One bag | 4 wheelbarrows (16 head pans) | 1:8 | 20 | 3.5 |

| One bag | 5 wheelbarrows (20 head pans) | 1:9 | 25 | 3.3 |

Materials Used in the Production of Sandcrete Blocks

The following materials are used in the production of sandcrete blocks:

Cement

Cement is a binder material that is used to hold the constituent (sand, gravels, etc) aggregates together to form a composite matrix. It is a carefully controlled combination of lime, silica, alumina and iron oxide. However, compounds of lime are the main ingredients of cement.

Hydration reaction takes place whenever water is added to cement, which results in a significant heat release. When concrete hydrates, a gel is created that holds the aggregate particles together and gives concrete its strength and water tightness when it hardens. Ordinary Portland Cement (OPC) or Limestone Portland Cement are the most popular form of cement used in construction projects. When making sandcrete blocks, Portland cement must adhere to all the specifications given in EN 197-1:2011 and NIS 444-1:2003, respectively.

Fine Aggregates

Fine aggregates are granular materials obtained by processing natural materials which pass through a sieve with a mesh size of 9.35 mm, almost totally pass through a sieve with a mesh size of 4.75 mm, and are mostly retained on a sieve with a mesh size of 200 (75 μm). For the production of sandcrete blocks, four different types of sand may be employed. They are river sand, sea sand, crushed stone sand, and pit sand. River sand is the most common in Nigeria.

In terms of volume, sand makes up around 75% of the mixture. It serves as a filler and is a reliable predictor of the sandcrete block’s anticipated compressive strength. The fundamental water to cement ratio is exceeded when using much finer sand because more cement and water are needed to coat the particles. The result is the production of weaker, more porous blocks. Too small natural dust grains can replace cement paste, cover grain surfaces, and form thin films, which hinder cement paste from lubricating the aggregates.

Tests for Fine Aggregates

Sieve Analysis

Sieve analysis is a laboratory test that measures the particle size distribution of a soil by passing it through a series of sieves. Soil retained on it is termed as gravel fraction. A set of British standard (BS) sieves of sizes – 1.0mm, 0.85mm, 0.60mm, 0.50mm, 0.30, 0.25, 0.180 and pan and a weighing balance were used for the analysis. The sieves were arranged by keeping the largest aperture sieve at the top and smallest aperture at the bottom.

The grading of soil is best determined by direct observation of its particle size distribution curve. The equation below is usually adopted in calculating the Uniformity coefficient Cu.

Cu = D60/D10

Where Cu is the Uniformity coefficient, D60 is the particle diameter corresponding to 60% finer on the cumulative particle-size distribution curve and D10 is the particle diameter corresponding to 10% finer on the cumulative particle-size distribution curve. If Cu < 4.0 the soil is poorly graded; if > 4.0 the soil is well graded. Well graded sands should be used for the production of sandcrete blocks.

Specific Gravity

The weight of a particular volume of fine aggregate (sand) to the weight of an equivalent volume of water is known as its specific gravity. Sands have a specific gravity of about 2.65. Specific gravity is considered to be a measure of strength or quality of a material.

To carry out a specific gravity test, the following procedure can be adopted:

An empty density bottle will be cleaned, dried, weighed and designated (W1). The bottle will be filled with one-third of the total volume of the sand sample, weighed and designated (W2). The bottle is then filled with distilled water, weighed and designated (W3). Then the content of the bottle is discarded and rinsed thoroughly. The bottle is then filled with distilled water to the meniscus, weighed and designated (W4). The Specific gravity (G) is then calculated using the equation below;

G = (W2 – W1)/[(W4 – W1) – (W3 – W2)]

Water

Water reacts with cement to produce the hydration reaction. The amount of water utilised in the mixing process has a significant impact on the workability and strength of sandcrete. To make concrete or sandcrete, water must be devoid of suspended solids, inorganic salts, acids, and alkalis, as well as algae, oil contamination, and acids and alkalis. It is advised to use potable water that complies with NIS 554:2007 standard when making sandcrete blocks.

Mechanical Properties of Sandcrete Blocks

The mechanical properties that are frequently declared in sandcrete blocks are the bulk density, water absorption, and compressive strength.

Bulk Density

Density is the quantity of an element’s or material’s particles packed into a specific volume. The density of the substance increases with the degree of particle packing. Therefore, higher levels denote a similar level of compaction. Mathematically, this is the mass of the masonry unit divided by the dimensions volume:

Bulk Density = mass of block (kg)/dimensional volume of block (m3)

The density is masonry units is determined in accordance wit BS EN 772-13:2000. In Nigeria, a minimum density limit of 1920 kg/m3 is recommended for individual sandcrete blocks, and 2020 kg/m3 for an average of three or more blocks.

Water Absorption

This is the amount of water that a block unit will absorb when submerged for the specified amount of time in the water at room temperature. It is stated as a percentage of the dry unit of the block’s weight. The weight of water absorbed when the block unit is partially submerged in water for one minute is the absorption rate. Additionally, it is also defined as the amount of water that a brick absorbs in the first minute after coming into contact with water.

The procedure for obtaining the water absorption of masonry units is described in in EN 772-11:2011.

It is expressed mathematically as;

Water absorption = (mass of saturated block (kg) – mass of dry block (kg)) / volume of block (m3).

The water absorption rate is determined by measuring the decrease in mass of the saturated block and surface dry sample. To achieve this, block samples whose weights had been taken in the dry state and noted as (M1), were fully immersed in water. The time taken for full immersion was noted, and a period of twenty-four (24) hours was allowed to elapse. After 24 hours, the weight of the wet block samples was recorded as (M2). The difference between the dry and wet weights of each block was calculated by subtracting the dry weight from the wet weight. The percentage absorption was calculated using the Equation below.

Water absorption (%) = [(M2 – M1)/M1] × 100

The ASTM C140 recommended maximum water absorption capacity of 240 kg/m3. The maximum water absorption specified by the Nigerian Standard is 12%.

Compressive Strength

A compressive strength test is used to assess the quality of a block unit and its response to curing. It is described as the unit’s capacity to sustain an axial load that is applied to either the block’s bed face or its edge or the ratio of the crushing load that a sample can sustain to its net area. The declared compressive strength of the block by the manufacturer shall be the characteristic 5% fractile fc or the mean 50% fractile fm.

The compressive strength of sandcrete blocks should be evaluated in accordance with EN 772-1:2000. When the anticipated compressive strength is less than 10 N/mm2, the crushing machine should be loaded at a rate of 0.05 (N/mm2)/s.

It is expressed mathematically as;

Compressive strength = maximum crushing load (N) / minimum surface area (mm2)

Sandcrete hollow blocks have a minimum strength requirement of 2.5 N/mm2 for 150 mm and 3.45 N/mm2 for 225 mm, according to NIS 87:2007. The factors affecting this property are water-cement ratio, degree of compaction, fine aggregate (grade, texture and shape characteristics), cement type, the efficiency of curing, amount of mixing water, and mix proportion.

Production of Sandcrete Blocks

The advent of various quickly assembled machines and other manually operated frameworks for the manufacture of masonry units is a significant factor contributing to this rise in the number of such production facilities. The top three methods of sandcrete blocks production are:

- Hand ramming compaction moulds.

- Manual tamping compaction frame.

- Motorised vibration machine.

All three methods employ both horizontal and vertical orientations in production. It is rare to see block manufacturing industries employing all three forms of production. Every block production industry typically uses only one orientation for the creation of block units for a specific type of compaction mechanism. During production, several manufacturers employ various compaction techniques with various orientations.

Hand Ramming Compaction Moulds

The equipment comprises of a steel mould box that has been prefabricated and moulded to the required size of the block. It is designed so that when the cement and sand mixture is rammed together to create a sandcrete block, the resulting shape precisely fits the mould and so adheres to the necessary specifications. The compressed wet unit can be removed after hand ramming thanks to a detachable steel plate sitting at the bottom. The mould box has two curved steel handles that make it easier to remove the compacted unit.

A wooden bat in the form of a chisel serves as the compaction tool. The cement-sand mixture is brought up against the flat end of the bat, which is then driven over it and inserted into the steel mould. The compacted unit is taken out by slamming the box upside down. In order to receive the block, the opening end is eventually supported by a wooden pallet. The unit is turned upside down, and a removable steel plate now rests on top of it.

This is the commonest approach of block moulding in the rural areas of Nigeria.

Manual Tamping Compaction Frame

This compaction technique uses a steel framework with a mould supported by four legs as its equipment. Although the exact finishing height varies depending on the manufacturer, it is often around 1.0 m high. The sole lever mechanism is attached to a base plate that accommodates the mould. The means of compaction is another plate (top plate) covering with an adjacent handle. When tamping, the top plate is always weighed down with a thick steel piece to apply pressure to the cement-sand mixture effectively.

Pulling down the tubular length by the frame moves the lever system. When compaction is complete, this action raises the completed product for collection. The adjacent handle is used to aid with compaction. Depending on the needed level of consolidation, the operation is repeated at least four times. For stability, the legs are braced, and the compacting pressure varies.

Motorised Vibration Machine

Unskilled labour can operate this equipment because it is designed to be simple to use. Because of the little maintenance it requires, the design is ideal for remote locations. Furthermore, the machine can be designed to run by diesel engines as well as electric motors. For stability and safe handling, robust frames are used in its design. It is controlled by three levers, and a constant hydraulic pressure is generated. The structure is 1.85 metres high.

It is powered by a motor that is tucked away beneath the wooden pallet on which the mould is set. The diesel variants use a roller that is turned by a fan belt that is fixed over the motor. The fixture on the motor, a metallic mass, collides with the underside of the wooden pallet, causing actual vibration. The longest lever, which is typically on the right side of the machine, is used to remove the moulded unit.

Actual compaction is accomplished by pressing down on the cement-sand mixture in the mould below with the “presser.” The highest lever is used to achieve this. The vibration is turned off with a second lever. The final and longest lever on the right lifts the mould gradually to enable quick removal of the compacted unit. The amount of compacting pressure from the motorised vibration machine is fairly constant.

In research conducted in Nigeria, the NIS’s specified compressive strength for 150 mm (6 inches) sandcrete blocks at 28 days of curing was not met by either manually or mechanically operated methods (though a mix ratio of 1:9 was adopted in the study). Both manually and with the aid of a vibrating machine, nine (9) inches sandcrete blocks were produced, and they met all Nigerian Industrial Standards specifications.

However, blocks made using a vibrating machine had a larger compressive strength than those made by hand. The vibrating block moulding machine produces sandcrete blocks with the highest compressive strength of all the techniques used because it achieves appropriate compaction. Additionally, compared to the other two methods, the vibrating machine-produced sandcrete blocks absorbed more moisture. Another study from Ghana found that using compaction in the vertical orientation with motorised vibration satisfies the required standards.

Quality Control Tips for Block Production

- Water, sand, and aggregates must be clean and devoid of organic contaminants.

- Ideally, the sand to be used for block production should be dry. When wet, the moisture content and the water absorption should be determined to effectively control the water-cement ratio.

- Cement and aggregate must be mixed until the colour is uniform.

- Only add enough water to the mixture to make it workable.

- The wheelbarrows used for measurement (65-litre builder’s wheelbarrows) should not be heaped.

- All mixtures should never be retempered by adding more water because doing so weakens the final product and should be used up within two hours of initial mixing.

- Complete compaction is required. Avoid too little or inadequate compaction since it reduces the strength of the block.

- Blocks need to be cured after demoulding. Curing is the process of keeping the blocks at an ideal temperature and moisture level to promote the hydration of the cement and the development of maximum strength. The curing period for blocks should be at least 14 days.

Nice Job, sir. I got value.

This is w very good information for practicing qnd builders and students alike. Thank you for this

Very helpful!

More strength.

Very resourceful information . Thank for sharing

you made my day.. thanks alot…more strength and progress to your knowledge

That’s great!

Thank you, for this impressive technical information.