Is there a better way to show and view a project than by digital twin? For example, suppose you plan to stay true to the design of a project during construction. Is there a better way to achieve this than by digital twin? Perhaps what comes to your mind when you hear “digital twin” is BIM. But, then, you may be surprised to know that digital twin goes beyond BIM.

For instance, BIM focuses on the system and sub-systems that ensure a building is constructed correctly. However, digital twin can be a combination of a building and a computational model to monitor, manage, and optimize the building. Thus, digital twin concentrates on the operation, performance, and functionality of the building, including use patterns, occupant behaviours, and space utilization. Nevertheless, both tools are vital in this age of intelligent building design, operation, maintenance, and management.

This article covers everything about digital twin in the architecture, engineering, and construction (AEC) industry, including the purpose, types, examples, and benefits of digital twin in construction. By reading this article, you will discover why digital twin is an essential tool in the construction industry and built environment and why you should now adopt and invest in digital twin.

Purpose of Digital Twin

At present, digital twin is growing in importance in the AEC industry because it is used to integrate real-time data from an existing asset with its digital representation to provide insights across the asset’s lifecycle. Digital twin is a proven game-changer in the AEC industry because it solves significant asset design, construction, and operation challenges. Adopting digital twins is also the best way to improve asset performance.

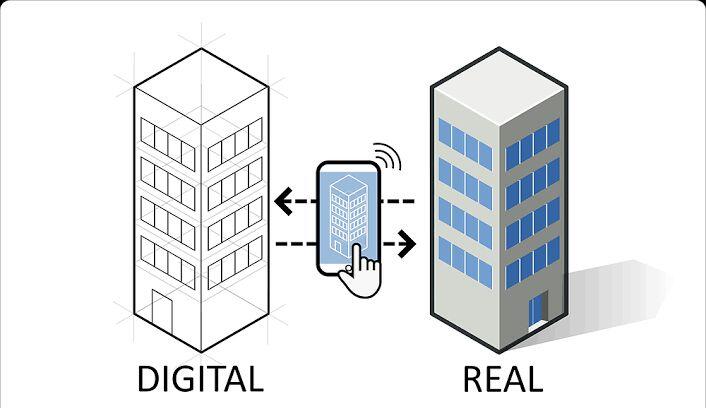

When you think of digital twin, virtual creations or exact digital replicas of an asset should come to your mind. For example, digital twin is like the 3D interior renderings of a building, and it is a tool that helps to utilize, manage, and optimize the spaces in the building. Thus, with the digital twin, you can easily make simulations and predictions based on real-world data and conditions to make informed decisions and develop failure-proof working methods.

You may ask where BIM comes in or how digital twin uses BIM. The fact is that BIM remains the most efficient path to creating an accurate, high-value digital twin. Usually, BIM uses the data created during the planning and design of a project. Likewise, digital twin uses this same data and the data created during the construction and operation of the completed project. Thus, this data can also be used to make calculated and informed decisions for future projects.

Types of Digital Twin

Depending on the degree of maturity and digital transformation you desire, the types of digital twin are briefly discussed below.

Descriptive twin

3D architectural models and renderings and BIM comprise descriptive twin. Descriptive twin provides data and editable visual and photorealistic representations of a project for scheduling construction processes and actual construction.

Informative twin

When you need to make informed decisions about facility management operation and estimation, you need information twin. Information twin involves using BIM with sensors, simulations, and operations data to draw insights at any given time within an asset’s lifecycle.

Predictive twin

Predictive twin involves using BIM with IoT technologies to track, capture, visualize, and analyze real-time data to identify potential issues during an asset’s lifecycle.

Comprehensive twin

Comprehensive twin involves leveraging BIM and AI for data-based advanced modelling and simulation to carry out prescriptive analysis and make recommendations to aid decision-making in future situations.

Autonomous twin

An autonomous twin is the ideal digital twin. Unlike comprehensive twin, where professionals still make final decisions, autonomous twin goes further to make decisions through AI-driven advanced simulation and 3D visualization algorithms.

Examples of digital twin

A digital twin is several things to the AEC industry, mainly because it is linked to assets, the spaces in assets, and the people who use these assets and spaces. For instance, digital twin is a tool for safety planning, asset management, space optimization, and improving occupant or employee experience. Examples of digital twin in the AEC industry are highlighted below.

• Developing new building construction models

There are several designs that architects conceive, but that never come to reality. This happens because architects sometimes need clarification on the practicality of such designs and if these designs meet all stability and safety requirements. To make matters worse, unfortunately, it is almost impossible to test such designs in the real world to see if they will work or not because of the capital, time, and other resources involved. However, a digital twin can solve this challenge.

With a digital twin, architects and other professionals in the AEC industry can test a design idea in reality-based simulations that would use real-world data and involve all the necessary real-world factors. Similarly, they can test such design’s stability, safety, sustainability, and practicality and get accurate feedback as if the design was executed in the real world.

• Reduction of construction and operating costs during building renovations

One significant advantage of digital twin is that it makes coordinating teams and construction processes easier. In addition, one can run several sequencing and logistics scenarios in advance. Thus, giving you an idea of what you are to do and how you are to do them during the construction of a project. Also, it is possible to feed back real-world data to the digital twin in cases where situations and events change.

• “What if” analysis of safety systems and emergency action plans

With “what if” analysis, you can simulate a scenario to know how a particular asset is performing and will perform under specific conditions. For example, a digital twin can be used to understand how a rail line was designed and constructed, how it functions, and its limitations. Similarly, a digital twin can provide workers with real-time tracking and alerts of work areas. Thus, reducing risks to workers, making construction attractive to people, and increasing overall efficiency and work quality on construction sites.

• Productivity and collaboration improvements through space delegation

Important information about an existing asset can be stored, analyzed, and updated throughout the asset’s lifetime. This information becomes helpful in making informed and calculated decisions when embarking on future projects. This information can also assist with de-risking the execution of the project.

• Asset performance and sustainability optimization through use monitoring

Professionals can improve the performance and sustainability of an asset from the insights obtained from a digital twin. For example, a digital twin can be used to predict maintenance events that may arise and plan the required maintenance activities. Consequently, unexpected circumstances and maintenance costs will be reduced throughout the asset’s lifetime. Furthermore, a digital twin can detect a fault or abnormality in a building and automatically dispatch a worker to rectify such issues without delay.

Benefits of digital twin

BIM is known to be very analytical. However, digital twin improves the digital capabilities of BIM and makes it easier for asset owners, operators and managers to visualize the real-time status, working conditions, and position of physical assets. Some benefits of digital twin for firms, owners and managers in the AEC industry are discussed below.

• Competitive edge

If you own a firm, digital twin can differentiate you from your competitors and put you ahead of them. In addition, with digital twin, firms can prove to their clients that they can provide them value and a broader range of services by leveraging technology to harness and utilize real-time data.

• Savings on money

Digital twin allows firms, asset owners, operators and managers to make informed and calculated decisions, thus helping to save cost and extending the value and lifecycle of assets.

• Savings on time

Usually, there are conversations between firms and stakeholders before a project kicks off. These conversations and collaborations help to prioritize the use and performance requirements of such projects or assets. Therefore, it becomes easier to plan to achieve the project goals and eliminate time wastage. Similarly, asset owners and operators can seamlessly proceed with operating the asset without having to bother about misplaced operation or maintenance documents.

• Streamlined facility management

Digital twin usually offloads most of the burdens of asset management. For instance, a digital twin of an asset can be used to spot the problem areas and provide potential solutions to the problems that technicians can work with.

Conclusion

A digital twin is simply an exact, digital, and dynamic replica of an asset after its design and construction, for example, a building. Thus, the digital twin of the building can change with its use, just like the physical building, because it is responsive to data input. Its use will also change as more data is supplied from sensors, IoT, and AI.

Just like BIM technology has become indispensable to the AEC industry, so is digital twin technology, especially for facility management. However, models and data from BIM are of little or no use to asset owners, operators, and managers once a project is completed. Therefore, a digital twin is vital for asset owners, operators and managers, and professionals in the AEC industry because it provides insights to optimize assets, systems, and workplaces.

References

[1] Deng, M., Menassa, C. C., and Kamat, V. R. (2021). “From BIM to Digital Twins: a Systematic Review of the Evolution of Intelligent Building Representations in the AEC-FM Industry”. ITcon 26, 58–83. Doi:10.36680/j.itcon.2021.005

[2] Autodesk, Inc. (n.d.). Retrieved from https://www.autodesk.com/solutions/digital-twin/architecture-engineering-construction