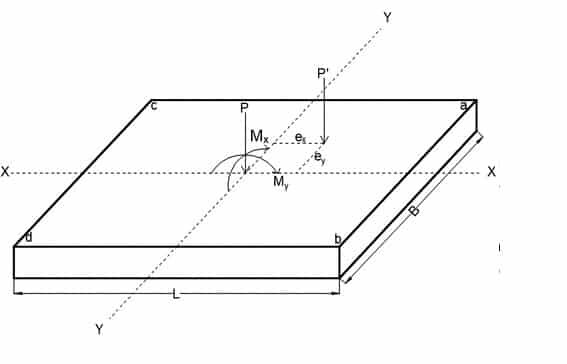

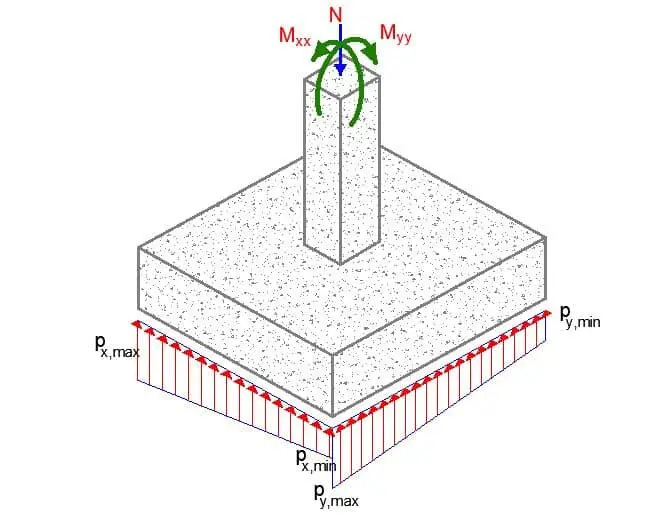

A biaxial eccentrically loaded pad footing occurs when the column transmitting load to the foundation is subjected to compressive axial force and bending moment in the two principal axes. As a result of the biaxial bending, two eccentricities ex and ey of the axial load occur on the pad footing, thereby leading to non-uniform pressure distribution on the foundation. The effects of such non-uniform pressure distribution must be accounted for during the geotechnical and structural design of the pad foundation.

This article will consider the geotechnical and structural design of a biaxial eccentrically loaded pad footing. The footing for a single column may be made square in plan, but where there is a large moment acting about only one axis it may be more economical to have a rectangular base.

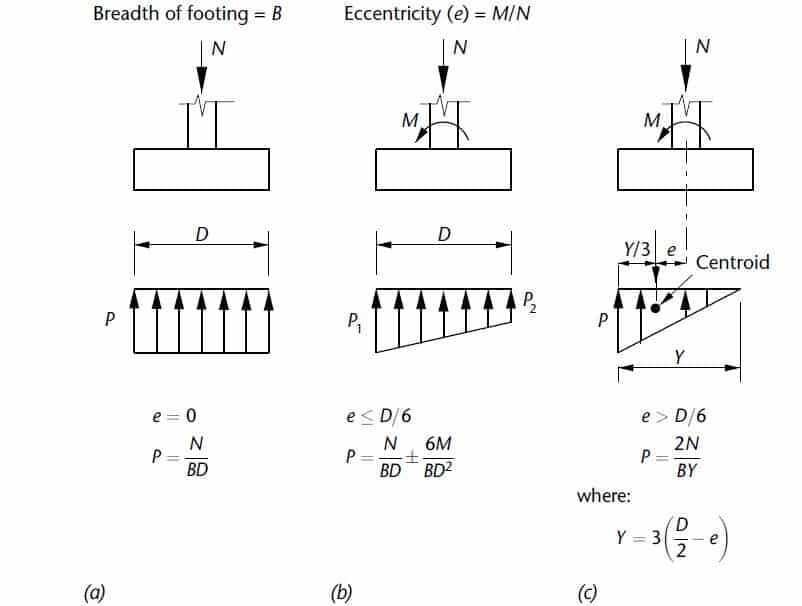

When a bending moment M and axial force N are acting on a pad foundation, the pressures are given by the equation for axial load plus bending. This condition is valid provided there is positive contact between the pad base and the ground along the complete length D of the footing so that;

p = N/BD ± My/I

where I is the second-moment area of the base about the axis of bending and y is the distance from the axis to where the pressure is being calculated.

Substituting for I = BD3/12 and y = D/2, the maximum pressure is;

pmax = N/BD + 6M/BD2

and the minimum pressure is;

pmin = N/BD – 6M/BD2

For biaxially loaded footings, this pressure must be verified in both directions, and the maximum pressure should not exceed the allowable bearing capacity of the soil. Furthermore, the reinforcement design must also be carried out in both directions.

Design Example of Biaxial Eccentrically Loaded Pad Footing

A 1500 x 1500mm pad foundation is subjected to the following loads from a 250 mm x 250 mm square column;

Permanent load axial load; FGz1 = 650.0 kN

Variable laxial load; FQz1 = 135.0 kN

Permanent moment in x; MGx1 = 25.0 kNm

Permanent moment in y; MGy1 = 21.0 kNm

Variable moment in x; MQx1 = 13.0 kNm

Variable moment in y; MQy1 = 11.0 kNm

The design is to be done in accordance with EN1997-1:2004 incorporating Corrigendum dated February 2009 and the UK National Annex incorporating Corrigendum No.1

Pad foundation details

Length of foundation; Lx = 1500 mm

Width of foundation; Ly = 1500 mm

Foundation area; A = Lx × Ly = 2.250 m2

Depth of foundation (thickness of footing); h = 500 mm

Depth of soil over foundation; hsoil = 600 mm

Level of water; hwater = 0 mm

Density of water; γwater = 9.8 kN/m3

Density of concrete; γconc = 25.0 kN/m3

Column details

Length of column; lx1 = 250 mm

Width of column; ly1 = 250 mm

position in x-axis; x1 = 750 mm

position in y-axis; y1 = 750 mm

Library item: Column details output

Soil properties

Density of soil; γsoil = 18.0 kN/m3

Characteristic cohesion; c’k = 15 kN/m2

Characteristic effective shear resistance angle; φ’k = 25 deg

Characteristic friction angle; δk = 20 deg

Foundation loads

Permanent surcharge load; FGsur = 5.0 kN/m2

Self weight; Fswt = h × γconc = 12.5 kN/m2

Soil weight; Fsoil = hsoil × γsoil = 10.8 kN/m2

Column loads

Permanent load in z; FGz1 = 650.0 kN

Variable load in z; FQz1 = 135.0 kN

Permanent moment in x; MGx1 = 25.0 kNm

Permanent moment in y; MGy1 = 21.0 kNm

Variable moment in x; MQx1 = 13.0 kNm

Variable moment in y; MQy1 = 11.0 kNm

Design Approach 1 (DA 1) – Combination 1

Partial factors on actions – Combination1

Partial factor set; A1

Permanent unfavourable action – Table A.3; γG = 1.35

Permanent favourable action – Table A.3; γGf = 1.00

Variable unfavourable action – Table A.3; γQ = 1.50

Variable favourable action – Table A.3; γQf = 0.00

Partial factors for soil parameters – Combination1

Soil factor set; M1

Angle of shearing resistance – Table A.4; γφ’ = 1.00

Effective cohesion – Table A.4; γc’ = 1.00

Weight density – Table A.4; γg = 1.00

Partial factors for spread foundations – Combination1

Resistance factor set; R1

Bearing – Table A.5; γR.v = 1.00

Sliding – Table A.5; γR.h = 1.00

Bearing Resistance

Forces on foundation

Force in z-axis; Fdz = γG × [A × (Fswt + Fsoil + FGsur) + FGz1] + γQFQz1 = 1166.0 kN

Moments on foundation

Moment in x-axis;

Mdx = γG × (A × (Fswt + Fsoil + FGsur) × Lx/2 + FGz1x1) + γGMGx1 + γQFQz1x1 + γQMQx1 = 927.7 kNm

Moment in y-axis;

Mdy = γG × (A × (Fswt + Fsoil + FGsur) × Ly/2 + FGz1y1) + γGMGy1 + γQFQz1y1 + γQMQy1 = 919.3 kNm

Eccentricity of base reaction

Eccentricity of base reaction in x-axis;

ex = Mdx / Fdz – Lx / 2 = 46 mm

Eccentricity of base reaction in y-axis;

ey = Mdy / Fdz – Ly / 2 = 38 mm

Effective area of base

Effective length;

L’x = Lx – 2 × ex = 1409 mm

Effective width;

L’y = Ly – 2 × ey = 1423 mm

Effective area;

A’ = L’x × L’y = 2.005 m2

Pad base pressure

Design base pressure; fdz = Fdz / A’ = 581.6 kN/m2

Design angle of shearing resistance; φ’d = tan-1(tan(φ’k) / γφ’) = 25.000 deg

Design effective cohesion; c’d = c’k / γc’ = 15.000 kN/m2

Effective overburden pressure;

q = (h + hsoil) × γsoil – hwater × γwater = 19.800 kN/m2

Design effective overburden pressure;

q’ = q / γg = 19.800 kN/m2

Bearing resistance factors;

Nq = Exp(π × tan(φ’d)) × [tan(45 deg + φ’d / 2)]2 = 10.662

Nc = (Nq – 1) × cot(φ’d) = 20.721

Nγ = 2 × (Nq – 1) × tan(φ’d) = 9.011

Foundation shape factors;

sq = 1 + (L’x / L’y) × sin(φ’d) = 1.418

sγ = 1 – 0.3 × (L’x / L’y) = 0.703

sc = (sq × Nq – 1) / (Nq – 1) = 1.462

Load inclination factors;

H = 0.0 kN

my = [2 + (L’y / L’x)] / [1 + (L’y / L’x)] = 1.497

mx = [2 + (L’x / L’y)] / [1 + (L’x / L’y)] = 1.503

m = mx = 1.503

iq = [1 – H / (Fdz + A’ × c’d × cot(φ’d))]m = 1.000

iγ = [1 – H / (Fdz + A’ × c’d × cot(φ’d))]m + 1 = 1.000

ic = iq – (1 – iq) / (Nc × tan(φ’d)) = 1.000

Ultimate bearing capacity;

nf = c’dNcscic + q’Nqsqiq + 0.5γsoilL’xNγsγiγ = 834.0 kN/m2

PASS – Ultimate bearing capacity exceeds design base pressure

Design Approach 1 (DA 1) – Combination 2

Partial factors on actions – Combination2

Partial factor set; A2

Permanent unfavourable action – Table A.3; γG = 1.00

Permanent favourable action – Table A.3; γGf = 1.00

Variable unfavourable action – Table A.3; γQ = 1.30

Variable favourable action – Table A.3; γQf = 0.00

Partial factors for soil parameters – Combination2

Soil factor set; M2

Angle of shearing resistance – Table A.4; γφ’ = 1.25

Effective cohesion – Table A.4; γc’ = 1.25

Weight density – Table A.4; γg = 1.00

Partial factors for spread foundations – Combination2

Resistance factor set; R1

Bearing – Table A.5; γR.v = 1.00

Sliding – Table A.5; γR.h = 1.00

Bearing resistance (Section 6.5.2)

Forces on foundation

Force in z-axis;

Fdz = γG × (A × (Fswt + Fsoil + FGsur) + FGz1) + γQFQz1 = 889.2 kN

Moments on foundation

Moment in x-axis;

Mdx = γG × (A × (Fswt + Fsoil + FGsur) × Lx/2 + FGz1 × x1) + γGMGx1 + γQFQz1x1 + γQMQx1 = 708.8 kNm

Moment in y-axis;

Mdy = γG × (A × (Fswt + Fsoil + FGsur) × Ly/2 + FGz1 × y1) + γGMGy1 + γQFQz1y1 + γQMQy1 = 702.2 kNm

Eccentricity of base reaction

Eccentricity of base reaction in x-axis;

ex = Mdx / Fdz – (Lx /2) = 47 mm

Eccentricity of base reaction in y-axis;

ey = Mdy / Fdz – (Ly/2) = 40 mm

Effective area of base

Effective length;

L’x = Lx – 2ex = 1406 mm

Effective area;

A’ = L’x × L’y = 1.997 m2

Effective width;

L’y = Ly – 2ey = 1421 mm

Pad base pressure

Design base pressure; fdz = Fdz / A’ = 445.3 kN/m2

Ultimate bearing capacity under drained conditions (Annex D.4)

Design angle of shearing resistance;

φ’d = tan-1(tan(φ’k) / γf’) = 20.458 deg

Design effective cohesion;

c’d = c’k / γc’ = 12.000 kN/m2

Effective overburden pressure;

q = (h + hsoil) × γsoil – hwater × γwater = 19.800 kN/m2

Design effective overburden pressure;

q’ = q/γg = 19.800 kN/m2

Bearing resistance factors;

Nq = Exp(π × tan(φ’d)) × (tan(45 deg + φ’d / 2))2 = 6.698

Nc = (Nq – 1) × cot(φ’d) = 15.273

Nγ = 2 × (Nq – 1) × tan(φ’d) = 4.251

Foundation shape factors;

sq = 1 + (L’x / L’y) × sin(φ’d) = 1.346

sγ = 1 – 0.3 × (L’x / L’y) = 0.703

sc = (sq × Nq – 1) / (Nq – 1) = 1.407

Load inclination factors;

H = 0.0 kN

my = [2 + (L’y / L’x)] / [1 + (L’y / L’x)] = 1.497

mx = [2 + (L’x / L’y)] / [1 + (L’x / L’y)] = 1.503

m = mx = 1.503

iq = [1 – H / (Fdz + A’ × c’d × cot(φ’d))]m = 1.000

iγ = [1 – H / (Fdz + A’ × c’d × cot(φ’d))]m + 1 = 1.000

ic = iq – (1 – iq) / (Nc × tan(φ’d)) = 1.000

Ultimate bearing capacity;

nf = c’dNcscic + q’Nqsqiq + 0.5 γsoilL’xNγ sg iγ = 474.1 kN/m2

PASS – Ultimate bearing capacity exceeds design base pressure

Foundation design (EN1992-1-1:2004)

In accordance with EN1992-1-1:2004 incorporating Corrigendum dated January 2008 and the UK National Annex incorporating National Amendment No.1

Concrete details

Concrete strength class; C25/30

Characteristic compressive cylinder strength; fck = 25 N/mm2

Characteristic compressive cube strength; fck,cube = 30 N/mm2

Mean value of compressive cylinder strength;fcm = fck + 8 N/mm2 = 33 N/mm2

Mean value of axial tensile strength; fctm = 0.3 N/mm2 × (fck)2/3 = 2.6 N/mm2

5% fractile of axial tensile strength;fctk,0.05 = 0.7 × fctm = 1.8 N/mm2

Secant modulus of elasticity of concrete; Ecm = 22 kN/mm2 × [fcm/10]0.3 = 31476 N/mm2

Partial factor for concrete (Table 2.1N); γC = 1.50

Compressive strength coefficient (cl.3.1.6(1)); acc = 0.85

Design compressive concrete strength (exp.3.15); fcd = acc × (fck / γC) = 14.2 N/mm2

Tens.strength coeff.for plain concrete (cl.12.3.1(1)); act,pl = 0.80

Des.tens.strength for plain concrete (exp.12.1); fctd,pl = act,pl × (fctk,0.05 / γC) = 1.0 N/mm2

Maximum aggregate size; hagg = 20 mm

Ultimate strain – Table 3.1; εcu2 = 0.0035

Shortening strain – Table 3.1;εcu3 = 0.0035

Effective compression zone height factor; λ = 0.80

Effective strength factor; h = 1.00

Bending coefficient k1; K1 = 0.40

Bending coefficient k2; K2 = 1.00 × (0.6 + 0.0014/εcu2) =1.00

Bending coefficient k3; K3 =0.40

Bending coefficient k4; K4 =1.00 × (0.6 + 0.0014/εcu2) = 1.00

Reinforcement details

Characteristic yield strength of reinforcement; fyk = 500 N/mm2

Modulus of elasticity of reinforcement; Es = 210000 N/mm2

Partial factor for reinforcing steel (Table 2.1N); γS = 1.15

Design yield strength of reinforcement; fyd = fyk / γS = 435 N/mm2

Nominal cover to reinforcement; cnom = 50 mm

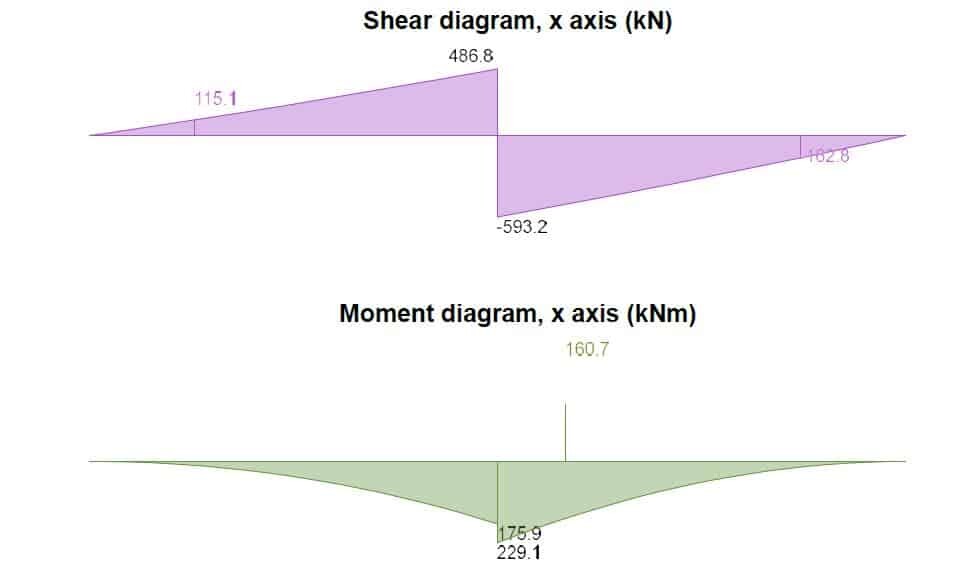

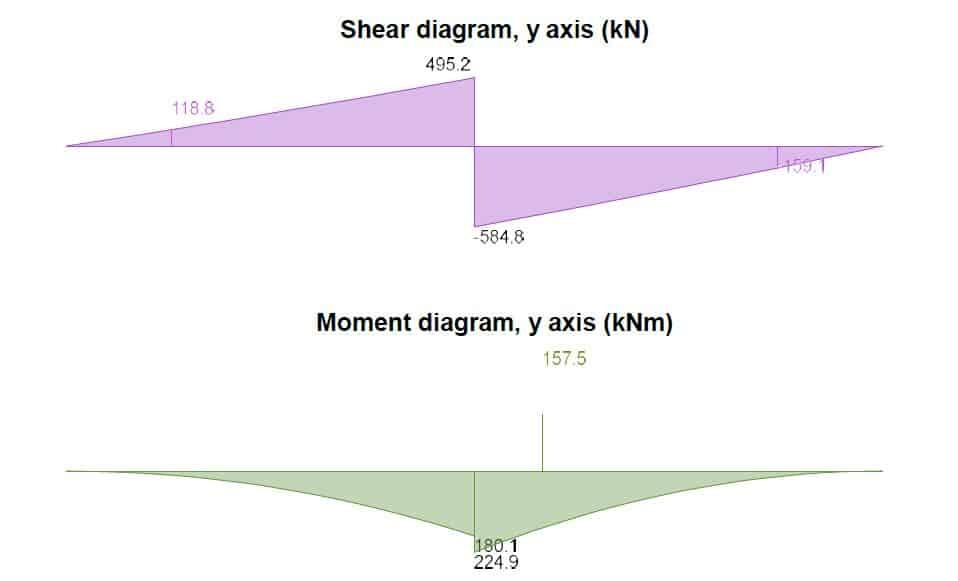

Rectangular section in flexure (x-axis)

Design bending moment; MEd.x.max = 160.7 kNm

Depth to tension reinforcement; d = h – cnom – φx.bot / 2 = 444 mm

K = MEd.x.max / (Ly × d2 × fck) = 0.022

K’ = (2 × h × acc/γC) × (1 – λ(d – K1)/(2K2)) × (λ(d – K1)/(2K2))

K’ = 0.207

K’ > K – No compression reinforcement is required

Lever arm; z = min(0.5 + 0.5 × (1 – 2K / (h × acc /γc))0.5, 0.95) × d = 422 mm

Depth of neutral axis; x = 2.5(d – z) = 55 mm

Area of tension reinforcement required;

Asx.bot.req = MEd.x.max / (fydz) = 876 mm2

Tension reinforcement provided;

10Y12@155 c/c bottom (Asx.bot.prov = 1131 mm2)

Minimum area of reinforcement (exp.9.1N);

As.min = max(0.26 × fctm / fyk, 0.0013) × Ly × d = 888 mm2

Maximum area of reinforcement (cl.9.2.1.1(3));

As.max = 0.04 × Ly × d = 26640 mm2

PASS – Area of reinforcement provided is greater than area of reinforcement required

Rectangular section in shear (x-axis)

Design shear force;

abs(VEd.x.min) = 162.8 kN

CRd,c = 0.18 /γC = 0.120

k = min(1 + √(200 mm / d), 2) = 1.680

Longitudinal reinforcement ratio;

ρl = min(Asx.bot.prov / (Ly × d), 0.02) = 0.002

vmin = 0.035k3/2 × fck0.5 = 0.381 N/mm2

Design shear resistance (exp.6.2a & 6.2b);

VRd.c = max(CRd.c × k × (100 N2/mm4 × ρl × fck)1/3, vmin) × Ly × d

VRd.c = 247 kN

PASS – Design shear resistance exceeds design shear force

Rectangular section in flexure (y-axis)

Design bending moment;

MEd.y.max = 157.5 kNm

Depth to tension reinforcement;

d = h – cnom – fx.bot – φy.bot / 2 = 432 mm

K = MEd.y.max / (Lx × d2 × fck) = 0.02

K’ = (2h × acc/γC) × (1 – λ × (d – K1)/(2K2)) × (λ × (d – K1)/(2K2))

K’ = 0.207

K’ > K – No compression reinforcement is required

Lever arm;

z = min(0.5 + 0.5 × (1 – 2K / (h × acc/γC))0.5, 0.95) × d = 410 mm

Depth of neutral axis;

x = 2.5(d – z) = 54 mm

Area of tension reinforcement required;

Asy.bot.req = MEd.y.max / (fydz) = 883 mm2

Tension reinforcement provided;

12Y12@125 c/c Asy.bot.prov = 1357 mm2

Minimum area of reinforcement (exp.9.1N);

As.min = max(0.26fctm / fyk, 0.0013) × Lx × d = 864 mm2

Maximum area of reinforcement (cl.9.2.1.1(3));

As.max = 0.04 × Lx × d = 25920 mm2

PASS – Area of reinforcement provided is greater than the area of reinforcement required

Crack control

Limiting crack width; wmax = 0.3 mm

Variable load factor (EN1990 – Table A1.1); y2 = 0.3

Serviceability bending moment; Msls.y.max = 99 kNm

Tensile stress in reinforcement; ss = Msls.y.max / (Asy.bot.prov × z) = 177.8 N/mm2

Load duration factor; kt = 0.4

Effective depth of concrete in tension;

hc.ef = min(2.5 × (h – d), (h – x) / 3, h/2) = 149 mm

Effective area of concrete in tension;

Ac.eff = hc.ef × Lx = 223000 mm2

Mean value of concrete tensile strength;

fct.eff = fctm = 2.6 N/mm2

Reinforcement ratio;

ρp.eff = Asy.bot.prov / Ac.eff = 0.006

Modular ratio; ae = Es / Ecm = 6.672

Bond property coefficient; k1 = 0.8

Strain distribution coefficient; k2 = 0.5

k3 = 3.4

k4 = 0.425

Maximum crack spacing (exp.7.11);

sr.max = k3 × (cnom + fx.bot) + k1k2k4 × φy.bot / ρp.eff = 546 mm

Maximum crack width (exp.7.8);

wk = sr.max × max([ss – kt × (fct.eff / ρp.eff) × (1 + ae × ρp.eff)] / Es, 0.6 × ss / Es) = 0.277 mm

PASS – Maximum crack width is less than limiting crack width

Rectangular section in shear (y-axis)

Design shear force; abs(VEd.y.min) = 159.1 kN

CRd,c = 0.18/γC = 0.120

k = min(1 + √(200 mm / d), 2) = 1.680

Longitudinal reinforcement ratio;

rl = min(Asy.bot.prov / (Lx × d), 0.02) = 0.002

vmin = 0.035k3/2 × fck0.5 = 0.381 N/mm2

Design shear resistance (exp.6.2a & 6.2b);

VRd.c = max(CRd.c × k × (100 × rl × fck)1/3, vmin) × Lx × d

VRd.c = 247 kN

PASS – Design shear resistance exceeds design shear force

Punching shear

Strength reduction factor (exp 6.6N); v = 0.6[1 – fck / 250] = 0.540

Average depth to reinforcement; d = 438 mm

Maximum punching shear resistance (cl.6.4.5(3)); vRd.max = 0.5vfcd = 3.825 N/mm2

k = min(1 + √(200 mm / d), 2) = 1.676

Longitudinal reinforcement ratio (cl.6.4.4(1));

rlx = Asx.bot.prov / (Ly × d) = 0.002

rly = Asy.bot.prov / (Lx × d) = 0.002

rl = min(√(rlx × rly), 0.02) = 0.002

CRd,c = 0.18 / gC =0.120

vmin = 0.035 k3/2 × fck0.5 = 0.380 N/mm2

Design punching shear resistance (exp.6.47);

vRd.c = max(CRd.c k (100rlfck)1/3, vmin) = 0.380 N/mm2

Design punching shear resistance at 1d (exp. 6.50);

vRd.c1 = (2d/d)vRd.c = 0.759 N/mm2

Punching shear perimeter at column face

Punching shear perimeter; u0 = 1000 mm

Area within punching shear perimeter; A0 = 0.063 m2

Maximum punching shear force; VEd.max = 1046 kN

Punching shear stress factor (fig 6.21N); β = 1.500

Maximum punching shear stress (exp 6.38);

vEd.max = β VEd.max / (u0 × d) = 3.582 N/mm2

PASS – Maximum punching shear resistance exceeds maximum punching shear stress

Punching shear perimeter at 1d from column face

Punching shear perimeter; u1 = 3752 mm

Area within punching shear perimeter; A1 = 1.103 m2

Design punching shear force; VEd.1 = 480.5 kN

Punching shear stress factor (fig 6.21N); β = 1.500

Design punching shear stress (exp 6.38); vEd.1 = βVEd.1 / (u1d) = 0.439 N/mm2

PASS – Design punching shear resistance exceeds increased design punching shear stress

Punching shear perimeter at 2d from column face

Punching shear perimeter; u2 = 63 mm

Area within punching shear perimeter; A2 = 2.250 m2

Design punching shear force; VEd.2 = 0 kN

Punching shear stress factor (fig 6.21N); β = 1.500

Design punching shear stress (exp 6.38); vEd.2 = βVEd.2 / (u2 × d) = 0.001 N/mm2

PASS – Design punching shear resistance exceeds design punching shear stress