In the construction of buildings, setting out is the critical first step on the path to successful construction. This process involves translating architectural plans onto the designated building site, and carefully identifying the exact locations and dimensions of foundations, walls, and other structural elements. This article discusses the process of setting out, exploring its methods, tools, and significance in building construction.

Upon gaining access to the designated building site, the contractor shall possess both the site layout plan and detailed drawings outlining the construction of the intended structure(s). Under prevalent building contract models, the onus of ensuring accurate setting out falls squarely upon the contractor. With site possession secured, preparatory measures and the critical process of setting out the building can commence. These activities can be broadly categorized into three distinct phases:

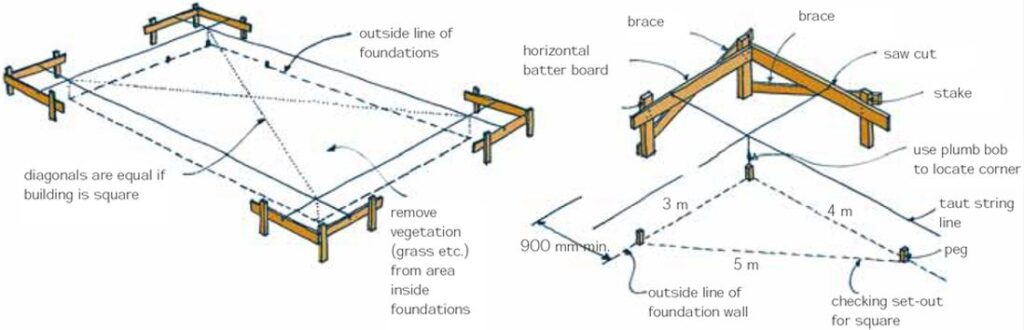

1. Site Clearance: The initial stage necessitates the removal of vegetation, debris, and any obstructive elements from the designated building area. This comprehensive clearing process ensures a level and stable platform, fostering accurate measurements and subsequent construction activities.

2. Building Setting Out: Following the precise dimensions and specifications detailed in the architectural plans, the contractor marks out the intended locations for foundation trenches. Stringent adherence to prescribed lengths, thicknesses, and angles for wall lines is achieved through the utilization of strings, pegs, or temporary structures. Rigorous verification at each step, employing measuring tools and surveying equipment, guarantees optimal alignment and dimensional accuracy.

3. Establishing a Datum Level: A crucial aspect of the setting-out process involves the establishment of a precise datum level. This reference point serves as the foundational elevation for measuring vertical distances throughout the construction process, ensuring consistent levels across the entire structure.

The Site Plan

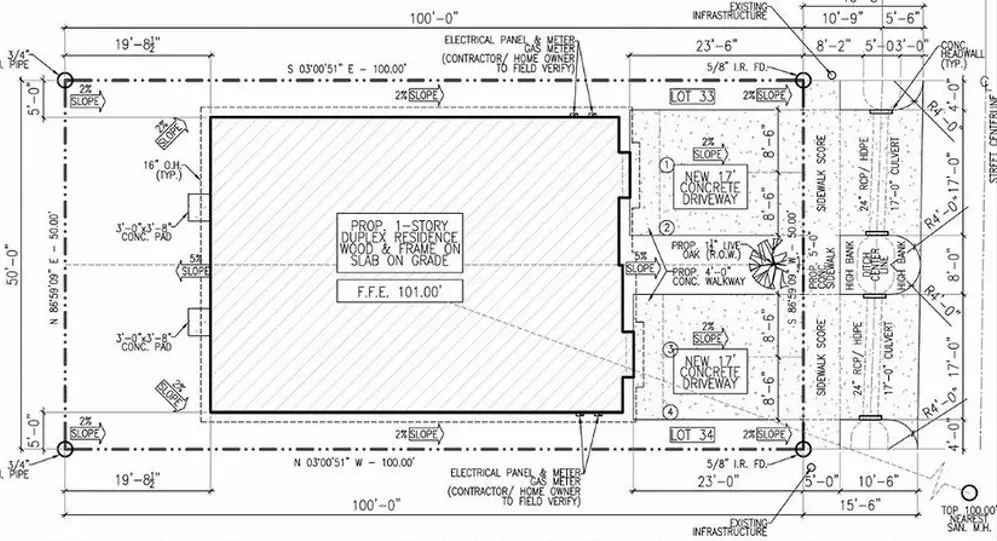

Every construction project commences with a prepared site plan, typically drawn to a scale of 1:500. This document maps existing site features, property lines, proposed buildings, setbacks, surrounding streets, roads, services, and ancillary works like car parks, retaining walls, and landscaping. It may even show new ground levels to guide development.

Setting Out

While the site plan serves as a drafted blueprint, its true merit lies in its practical implementation. The success hinges on the ability of onsite personnel to accurately translate the plan’s directives into physical reality. This process, known as setting out, ensures foundations are laid at the designated level and ground floors precisely match the intended height above the finished ground level. Each step relies on the accurate transfer of information from the plan to the actual construction site.

Constraints and Reference Points

The architect or engineer tasked with planning the site layout often encounters restrictions known as “building lines.” These invisible lines dictate the building’s frontage, requiring a clear depiction of the site plan with precise referencing to fixed points.

Examples include road or pavement kerb lines and extensions of existing building frontages. Figure 3 exemplifies a typical site plan layout. In the absence of designated building lines, the building’s corner positions are determined by dimensions carefully measured from at least two established fixed points.

Essential Tools for Setting Out

To effectively execute the setting-out process, a specific toolkit is indispensable:

- Dumpy level, tripod, and staff: This trio enables precise levelling and height measurements.

- Wooden pegs: Sturdy pegs facilitate marking key points.

- Builder’s square: Useful for checking the orthogonality of angles

- Hammers and nails: Securing pegs efficiently requires hammering skills.

- Measuring tapes: Precise distance measurement is crucial.

- Builder’s line and level: This combination ensures proper alignment and horizontal reference.

- Measuring rods: Additional tools for accurate measurement tasks.

- Crosscut hand saw: Cutting materials for marking purposes.

- Timber boards: Useful for creating temporary structures or markers.

Process of Building Setting Out

The following established process is used in the setting out of buildings;

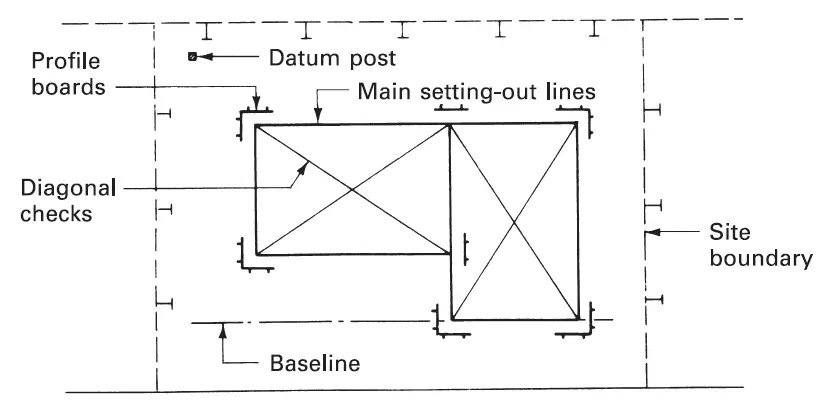

(1) Locating Fixed Reference Points (Baseline): The initial stage of setting out on a construction site involves identifying and verifying existing reference points employed during the preliminary survey. These points, often materialized as nails, pins, hooks, or markings, serve as crucial anchors for subsequent measurements. Re-measuring these points confirms their accuracy and ensures a reliable foundation for further site layout.

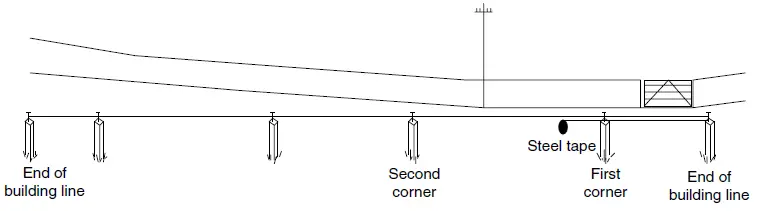

(2) Marking Building Corners and Baselines: For projects lacking predefined building lines, the initial step involves physically marking the building’s corners using wooden pegs with nails driven into their tops. Steel tape measurements taken from known fixed points, referencing dimensions provided in the site plan, guide the precise placement of these initial markers. Repeating measurements and ensuring their consistency further enhance accuracy.

(3) Utilizing Building Lines for Corner Placement: When building lines are present, their fixed positions allow for the deployment of a builder’s line stretched between nails marking the line’s ends. By measuring along this line with a steel tape, the locations of building corners can be established. Again, pegs and nails mark these corner points for easy visualization and reference.

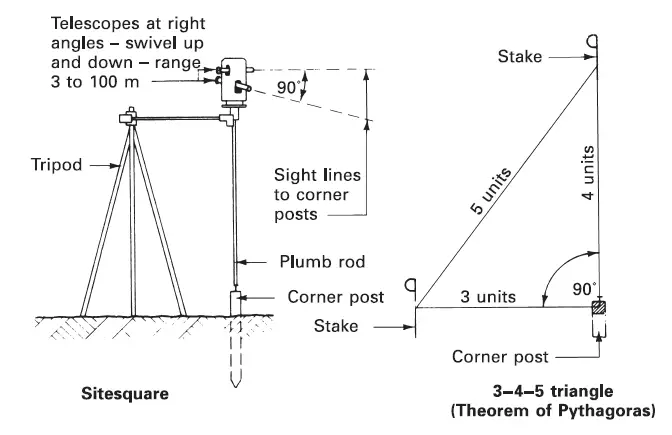

(4) Employing Pythagoras for Precise Positioning: With two building corners accurately defined, the remaining corners can be determined using the Pythagorean theorem applied to right-angled triangles formed by the existing points (Figure 6). Once all four corners are marked with pegs, a final verification step involves diagonally measuring the resulting rectangle to ensure minimal discrepancies.

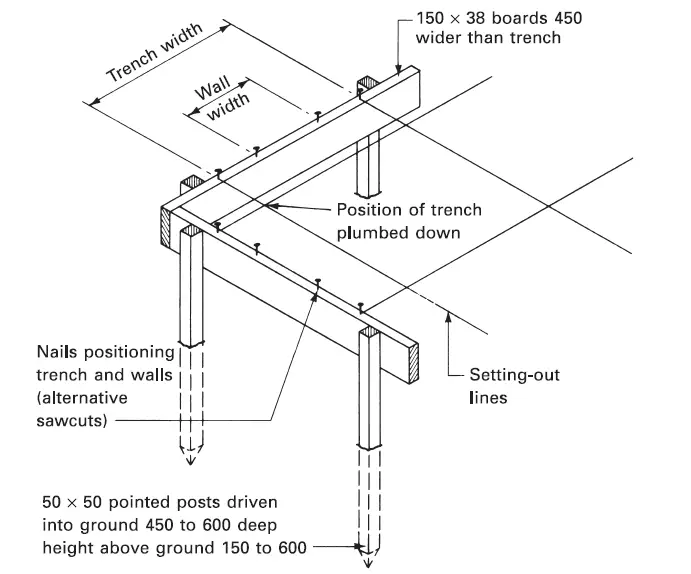

(5) Addressing Limitations of Basic Markers: The initial placement of corner markers using pegs and nails faces limitations, namely potential disturbance during subsequent construction activities and the lack of vertical alignment information. To overcome these limitations and establish robust reference points, the use of profile boards is necessary (Figure 7).

(6) Utilizing Profile Boards for Enhanced Functionality: Each profile board set is positioned at a building corner, strategically “looking” along two adjacent walls. These boards offer several advantages:

- Undisturbed by Subsequent Work: They are positioned outside the excavation area, ensuring their preservation throughout construction.

- Vertical and Horizontal Alignment: They provide reference points for both horizontal dimensions and vertical elevations.

- Repeatability: They facilitate the precise re-establishment of corner locations, measurements, and levels if needed.

While the builder’s lines strung between profile boards might initially hinder excavation activities, alternative methods for marking out excavation boundaries are employed during the later stages of foundation construction.

Digital Setting Out Equipment

While traditional methods using pegs and profiles remain prevalent, advancements in technology offer alternative approaches for setting out on construction sites. Large companies leveraging Electronic Position and Distance Measurement (EPDM) equipment can optimize efficiency and potentially eliminate the need for extensive use of temporary markers.

In such scenarios, one or two strategically placed pegs with nails, protected from disturbance, can serve as enduring reference points throughout the construction process. These key markers, established during the initial survey, facilitate the precise layout of various site elements, encompassing roads, sewers, house drains, and even the buildings themselves. This technology-driven approach streamlines the setting-out process while upholding accuracy and efficiency.

Conclusion

Setting out, though seemingly simple, is a cornerstone of successful construction. Its proper execution requires expertise, precision, and the use of the right tools. By understanding the process, embracing its significance, and leveraging available technologies, construction professionals can ensure a good and accurate alignment and positioning for every structure they build.

IAM HUPPY WITH EDCATIONAL CONTENT AIM ASTUDENT FROM KENYA SITTING MY LAST EXAM FOR NATIONAL DIPLOMA ON MARCH CONNECT ME TO PRACTCE UNDER YOU IN NIGERIA