A lintel is a horizontal structural member which spans across the supports of an opening such as a door or window in a building. Depending on the span of the opening, a lintel may be structurally significant or insignificant – considering whether it requires serious structural consideration or not. Lintels can be made of materials such as timber, concrete, or steel. Concrete lintels are usually provided with nominal reinforcement, due to the inherent low tensile strength of concrete. When a lintel is continuous in a building and connects all the structural members together, it is called a chained lintel.

In Nigeria, it is common to see residential buildings chained at the lintel level. What is meant by chaining is that all the structural members are joined monolithically at the lintel level with reinforced concrete. Chained lintels can also be called continuous lintels. This process is usually done when the blockwork is built alongside the columns of the building. It is rarely done in a purely framed building where the columns, beams, and slab are done before the blockwork panels are built.

Eye brows can be raised over this ‘wasteful approach’ of using excessive concrete and reinforcement on elements that are not ‘structurally significant’. This can lead to questions such as;

(1) Is it possible that the amount of money spent on constructing blockwork simultaneously with the frame and adopting a chained lintel offsets the cost of constructing a purely framed building?

(2) Can chained lintels be entirely avoided irrespective of the approach used?

(3) Are there special advantages of doing chained lintel in a building?

This issue is pertinent because the structural frame of a building is usually designed to stand alone without considering the effect of such lintels. Also, such arrangement is not usually captured in the structural drawings of a building, but it is done on site for low scale residential buildings. Why the extra cost? The lintels are usually 230 x 230 mm in dimension.

Advantages of chained lintels

The perceived advantages of chained lintels are as follows;

(1) It can improves the rigidity of the building. This is a no-brainer since more redundants are being added to the frame of the building. As a result, the building can behave more as a unit due to the increased linking members.

(2) It improves the robustness of the building.

(3) It can improve the lateral stability of the building, even though it is rarely critical in simple residential buildings such as duplexes in a region of no seismic event.

(4) It can cover up the inherent dimensional inaccuracies associated with building the blockworks and the columns at the same time, even though strict quality control can improve that.

(5) Introducing chained lintels reduces the buckling length of columns.

Disadvantages of chained lintels

(1) All the advantages highlighted above are usually catered for when designing the building as a pure frame. What is then the need of the extra advantages in terms of cost?

(2) The reinforcements provided in the building are the same as when no consideration for chained lintels is made.

(3) The construction speed is reduced.

A Structural Perspective

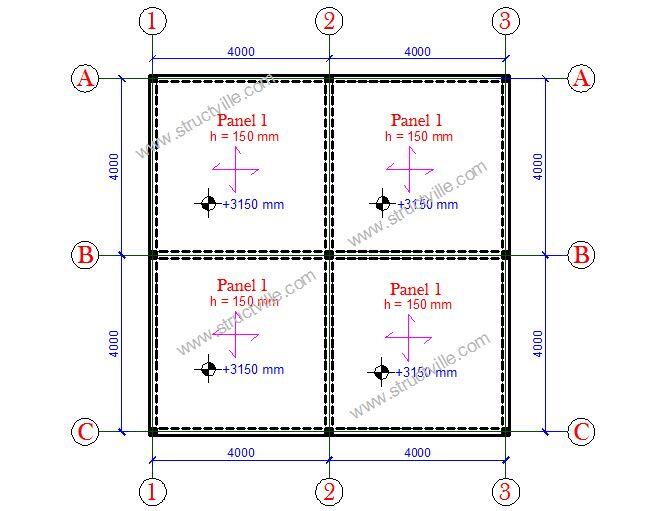

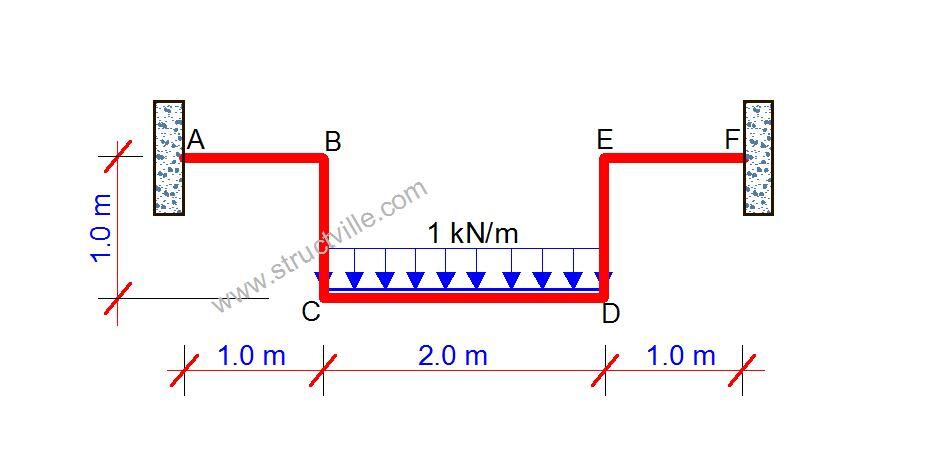

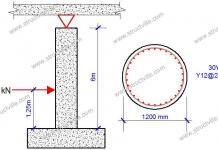

To look at this issue from a structural perspective, let us investigate the effect of chained lintels on the structural response of a simple two storey building under the effect of normal actions. In order to achieve this, let us model a simple two storey residential building and investigate its structural behaviour with and without chained lintels. The building data is shown below;

Building Data

Dimension of all columns = 230 x 230 mm

Dimension of floor beams = 450 x 230 mm

Dimension of roof beams = 300 x 230 mm

Thickness of floor slab = 150 mm

Dimension of lintels (model 2) = 230 x 230 mm

ULS action on floor slabs = 12 kN/m2

ULS action on floor beams (blockwork + rendering + selfweight) = 15 kN/m

ULS action on roof beams = 5 kN/m

ULS action on lintels = 3.5 kN/m

(N/B): All loads were assumed.

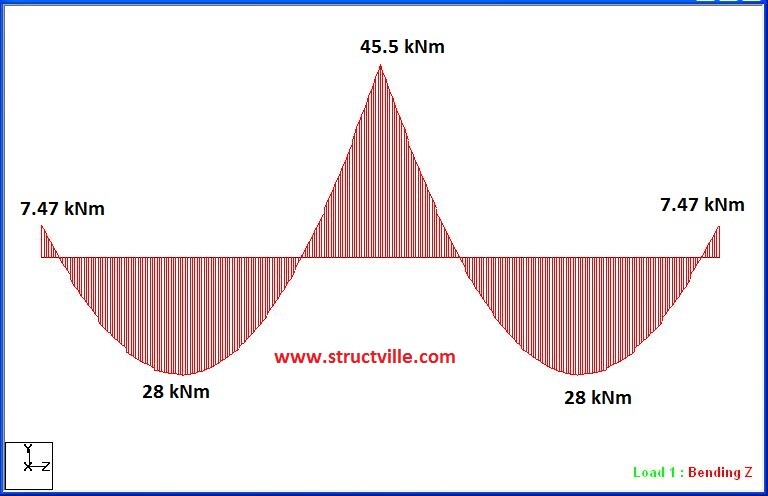

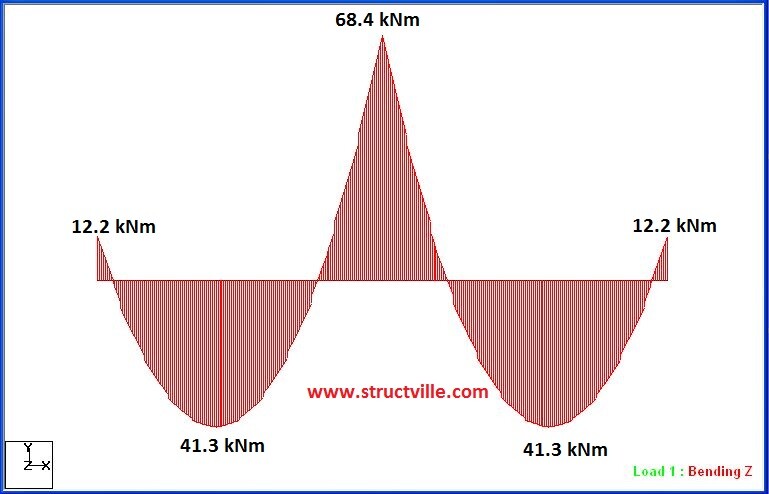

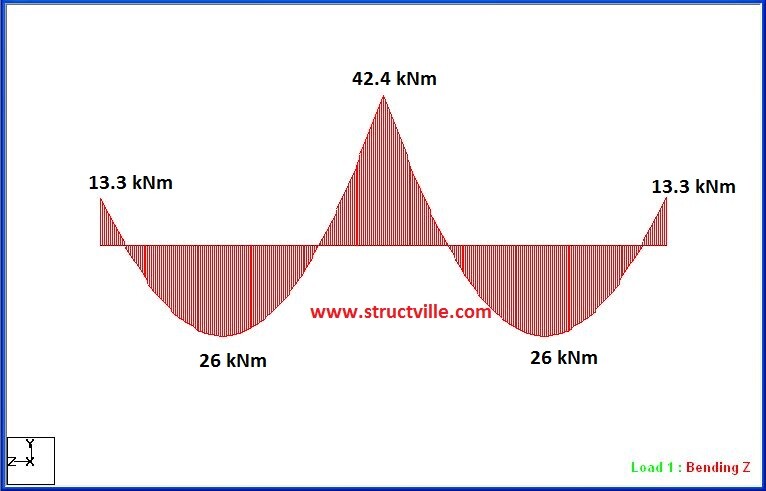

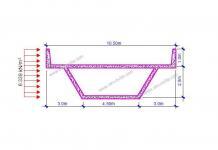

From the figures above, the maximum hogging moment on the internal and external beams are 45.5 kNm and 68.4 kNm respectively, while the sagging moments are 28 kNm and 41.3 kNm respectively.

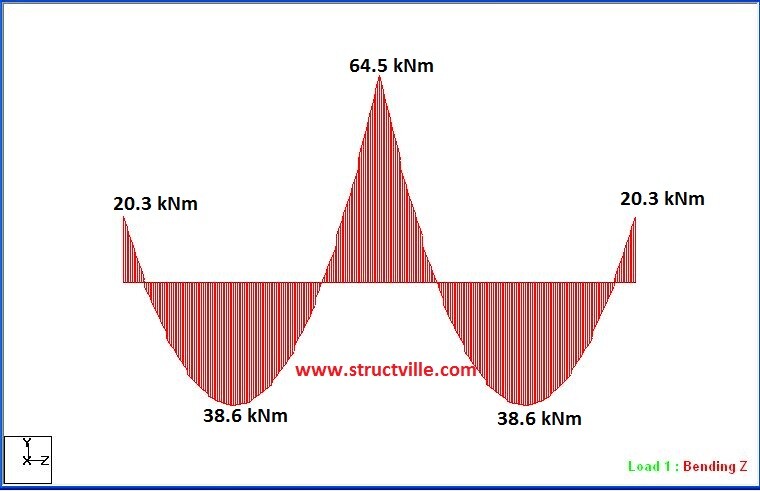

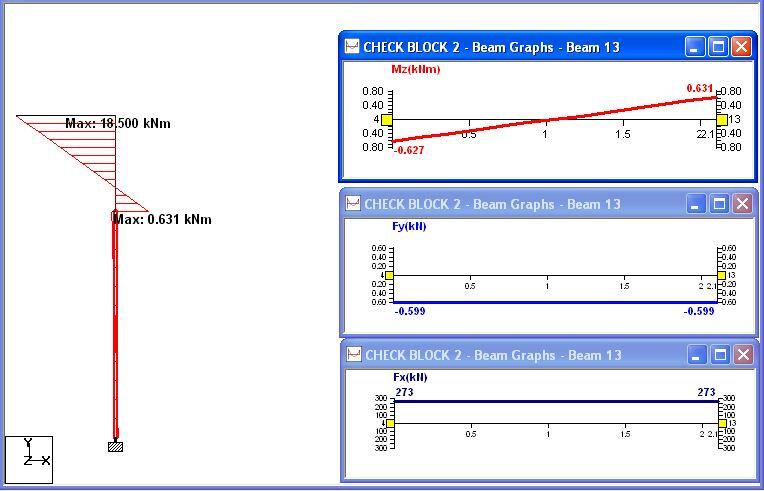

The results below show the building model with lintels and the internal forces acting on the building.

Comparison of results

Under the effect of gravity actions, the following results were observed in the structural members;

(1) Beams

In the building with chained lintel, the bending moment on the intermediate support of the external beam reduced by about 6.8%. However, the end support moment increased by about 43.8% (from 7.47 kNm to 13.3 kNm). A reduction in span moment was also observed for floor beams in buildings with chained lintel. This same behaviour was observed in the internals beams.

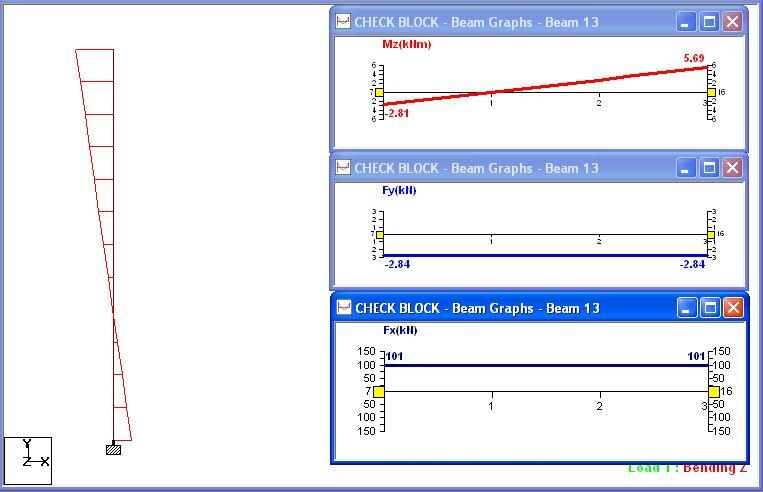

(2) Columns

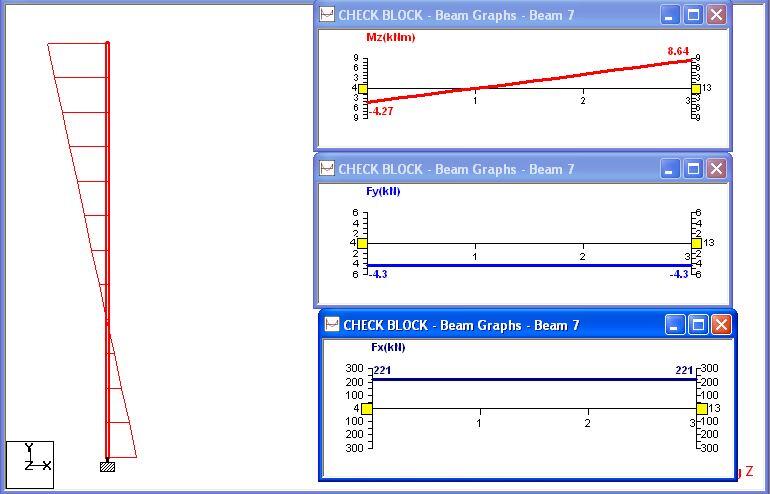

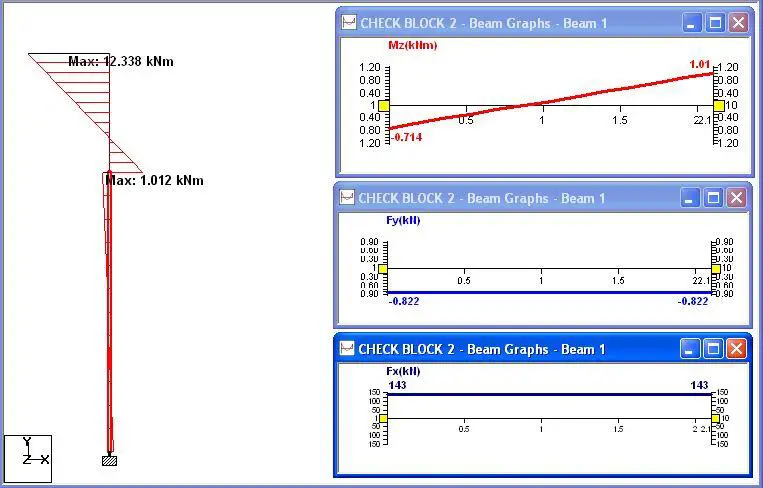

The bending moment in the corner columns increased from 5.69 kNm to 12.338 kNm when chained lintels were introduced. This is due to the fact that lintels are subjected to the load from the blockwork courses that get to the sofit of the beams. Axial load in the columns also increased from 101 kN to 143 kN. This same increase in internal forces was observed for the intermediate columns.

Therefore, introducing chained lintels appears to worsen action effects on the columns, but favours the floor beams, except for end support moments.

Limitation of the study: The loadings on the lintels appeared to be exaggerated, and some considerations were not made to reduce the wall load on the floor beams since the chained lintel will carry some of the loads. The author therefore welcomes discussions and further investigations in the study.

Thank you for reading.

Nice work ubani.

The assumption of using a chain lintel may be OK for a more robust structure. Sometimes in design of buildings, we often neglect wide opening for sliding doors(4.5m ) which have heavy Lintels.

Mostly the lintel in. Low cost building are only reinforced at the opened only. They are not frame to columns

The use of this so called chaining is an economic waste, av always advocate against i

Am not a fan of chained lintels in small residential buildings if personally supervised. Meanwhile I designed and built a factory building up to 8m high and necessitated the intermediate beam which acted as lintels for openings and as a tie to all columns along the external perimeter of the structure.

Well, I’m my opinion,

Chains are waste in some buildings but not all.

For example,

Blockwall of 125mm and 150mm width have lesser lateral stability both vertical and horizontal. Hence chain as lintels help improve wall stability especially in bungalows where columns are ignored.

But for 225mm walls, there’s no need for lintel or chains as it is more stable.

The advantages of chaining are mostly gotten if the need arises to renovate or remodel the building.

Any other advantages are exaggeration.

I am an advocate of fast tracking and post construction waste management, so we normally use offcuts at site for precast lintel which are just a small section and in turn saves money, time and wastes.

QS normally put lintel as an item under window and money are spelt out for it. However you can have a cost saving or value engineering by avoiding chain lintel.

I chain all my buildings for future change of purpose.lf windows and doors are to be repositioned, I don’t need to start introducing new lintel

Flexibility of locating the openings in future is the main advantage of chained lintels. In addition,filler wall thickness for interior walls can be reduced to half reducing gravity load on beams and columns. The wasteful expenditure is offset by increases stiffness of frames .

Hi

Are the walls acting as load-bearing walls?

If so, then the model needs some improvements:

1- where the lintel is on opening, it will act as (beam). but where the lintel is on block wall, it will act as (something like grade beam), I mean beams with some springs below. The is true

also for floor and roof beams.

2- In both models there isn’t grade beams to support the block wall of the ground floor.

Chain lintel should not be neglected in a massive building to avoid future cracks

Some of the comments here didnt consider the comparative analysis already done. Structural engineers shld digest the implication of increase of axial forces of the column due to lintel chaining which wasnt probably catered for during design rather it became a site necessity. Thereby causing additional pressure to an already designed maybe pad footing. Lintels are basically for doors, windows, and any other opening below the deck. If for any reason shld be significant to the structural stability then it shld be designed as ties and its tensile force applied at connections.

I guess , chained lintels is necessary in the building, especially reducing of loads in the building.

I’m building a warehouse and the site manager has introduced a chain at the bottom of the building, another one at the lintel level and wants to add another three coaches of block after the lintel. Is this advisable? The building already columns almost every six feet. I think this is an overkill and may be counter-productive. Can I get an advice?

I am a mechanical Engr, with structural and civil engineering experience.

In today’s practice; especially in area with loose soil, the chained lintel is used in the ground floor to boost the rigidity of the foundation when a simple pad foundation is used for a 2 storey building.

Furthermore introduction of a chained lintel in the first floor will offset the need of an entirely chained roof beam. The roof beam will only be chained at the external walls to support the parapet wall.