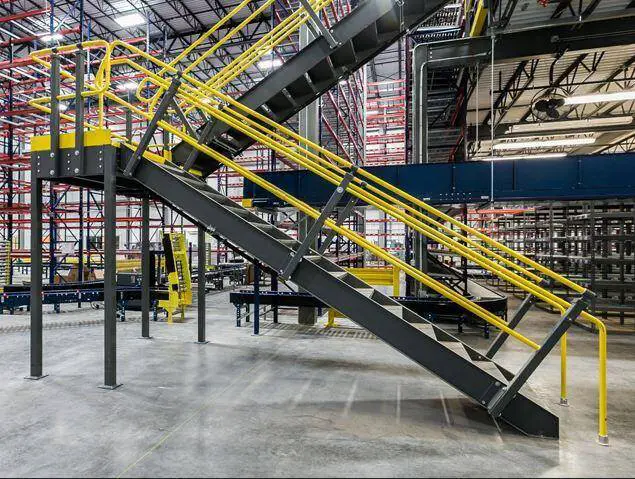

Steel staircase structures are usually considered secondary steelworks. Primary structures comprise the critical elements necessary for the strength and stability of the overall structural frame. This usually comprises the beams, columns, walls, slabs, etc. This frame serves as the support for all other building components. Any steelwork supported by the main structure, without needing to enhance its strength or stiffness, is called secondary steelwork.

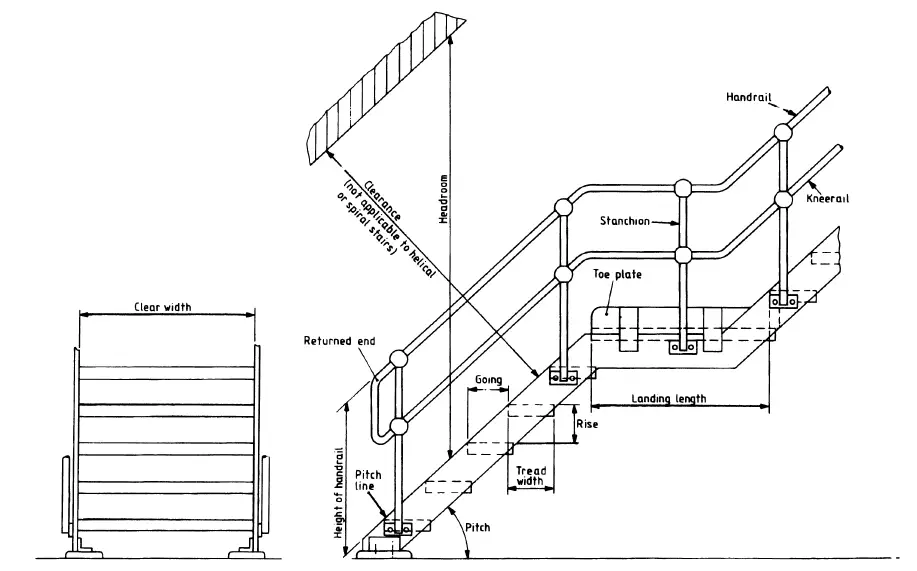

The essential elements of a staircase include treads, risers, stringers, landings, and their supports. These components can be configured in different ways to create stairs with varying levels of functionality, from simple utility to prominent architectural features. BS 5395, the code of practice governing the design, construction, and maintenance of straight stairs and winders, offers the guidelines described in the sections that follow.

Geometry of Steel staircase

The geometry of a staircase structure is usually determined by building regulation requirements. The relationship between rise, tread, and pitch must be such that the stair is safe and comfortable to use. It is essential to make all rises in a flight uniform, subject to the tolerances given in Clause 5.5 of BS 5359. The relationship between the rise and going for a stair should not change along the walking line, subject to the same tolerances.

The minimum clear width should be 600 mm for occasional one-way traffic, 800 mm for regular one-way traffic and occasional two-way traffic and 1000 mm for regular two-way traffic. Stairs that are often used by large numbers of people at the same time (assembly stairs in public buildings) should be designed with a large going and a small rise to achieve a maximum pitch of 33 degrees. Stairs that are used as means of escape may require a clear width greater than 1000mm.

All stairs are required to have a minimum of three and a maximum of 16 rises per flight and the clear width of all landings should never be less than the stair clear width. The length of a landing should be not less than the clear width of the stair or 850 mm, whichever is greater.

For steel staircases in industrial structures, there should be a change of line or direction of not less than 30° after 32 risers, for straight stairs, or 44 risers, for helical or spiral stairs. Landings at the head of a stair should be designed so that it is not possible to step from a platform or walkway onto the stair without a change in direction.

Typical dimensions for public stairs are:

- Rise: 100 – 190 mm

- Going: 250 – 350 mm

- Pitch: maximum 38 degrees

- Clear width: minimum 1000 mm.

The minimum pitch for straight stairs should be 30°

The maximum pitch for occasional access should be 42°

The maximum pitch for regular two-way traffic should be 38°

Treads

Treads should comply with the requirements for strength given in BS 4592 and should be slip-resistant or at least have a slip-resistant nosing not less than 25 mm wide. Treads on open riser stairs should overlap not less than 16 mm and have a nosing depth in the range of 25 mm to 50 mm to aid visibility.

Strings

Strings should be sufficiently robust to minimize lateral flexing of the structure and should not project more than 50 mm beyond the nosing of the bottom tread.

Loads and robustness

Industrial staircases need to be designed with consideration for accidental loads, particularly when they serve as emergency escape routes. It is important to ensure that these stairs can withstand potential damage caused by accidental loads without collapsing.

To achieve this, the connections between the stairs and the primary structure must be strong and well-designed, providing enough bearing area and tie resistance. When using individual treads, their design should account for the dynamic impact of repeated foot loading, and it is advisable to opt for a cautious and conservative approach to the design.

The dynamic response can be critical as steel stairs tend to have little inherent damping.

Other criteria – safety, slip resistance, durability, acoustic requirements and lighting requirements all influence stair design and are addressed in BS 5395.

Dynamics of Steel Staircase Structures

Footfall excitation is the primary dynamic load that significantly affects the behaviour of a staircase. Staircases can experience different types of footfall excitation, including the impact of a single person walking, a group of individuals going up or down the stairs together, and the impulse load generated when someone jumps from a height to a lower step.

The limitations in the design geometry of steel staircases lead to various approaches for different individuals when ascending or descending. Some people may choose to increase their step frequency to maintain their speed, while others may stick to the typical 25 step frequency.

Additionally, some individuals may take two or more steps at once, resulting in a higher impact load but reducing the step frequency. Due to these variations, it becomes challenging to provide a single or specific set of instructions for ascending or descending a staircase.

Slender staircases are characterized by their lightweight, leading to a low stiffness-to-mass ratio. As a result, these staircases have low natural frequencies, making the vibration serviceability criteria the primary design consideration. It is important to simulate the dynamic behaviour of a staircase using finite element analysis before construction to ensure that it meets the necessary dynamic and comfort requirements for users.

Design of Steel Staircase

Structural steel is the material commonly used in the design of industrial steel staircases. Grade S275 or S355 is commonly used. After the selection of the proper material, the next step is to design the individual components of the staircase. This includes the treads, risers, stringers, and landings.

The stringers are the beams that support the treads, risers, and landings, and they must be designed to carry the loads of the staircase. They are usually designed using I-beam sections, even though channel and rectangular hollow sections can also be used. They are usually subjected to bending moment, shear, axial, and torsional stresses.

The load from the tread can be transferred to the stringers as a series of concentrated loads or uniformly distributed loads depending on the manner of connection adopted. The stringer can be bolted or welded to a base plate or the primary structure.

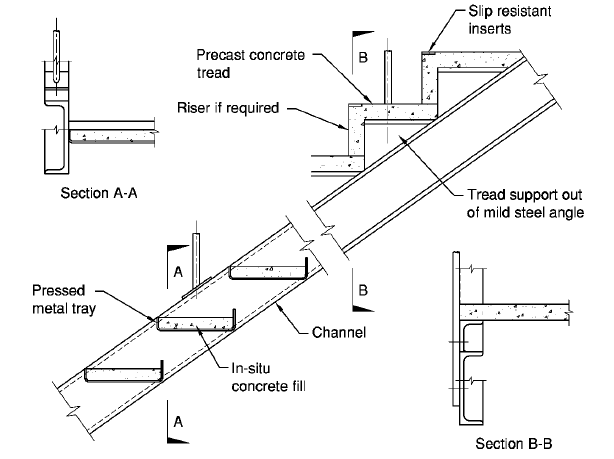

The treads and risers are the parts of the staircase that people will step on, and they must be designed to provide a safe and comfortable walking surface. The treads are commonly designed using chequered structural steel plates to provide slip-resistant surfaces. Angle or channel sections can be used to enhance the rigidity of the plates.

The landings are the platforms that people will use to rest and change direction, and they must be designed to be level and stable.

Forms of Construction

Stair flights, consisting of treads and risers, are supported by stringers to create a staircase. Typically, two flights are required per storey height, arranged at 180 degrees to each other, and should occupy a footprint not exceeding 6m x 3m (although larger stairs are allowed in assembly buildings). Each end of the stair flight connects to a landing.

The most straightforward stair construction involves placing the staircase internally, within an opening in the primary floor structure. In this case, both the floor level and half-level landings can be directly supported by the primary structure, allowing the stair flight to span between landings. The floor level landing can be designed as part of the staircase or as part of the floor structure. Stair treads can be positioned above or in the plane of the stringers.

When the treads are located in the plane of the stringers, the stringer depth resulting from minimum planning dimensions will be structurally sufficient. Additionally, if folded steel plates are used for both the treads and risers, the staircase will inherently have enough rigidity to respond adequately to dynamic forces. This construction method proves to be highly efficient.

However, if a staircase is placed at the edge of a floor slab, the support of landings, especially the half-landings, becomes critical.

Conclusion

Steel staircases are important structural elements used for providing vertical circulation in a building. Steel offers several advantages, such as high strength, durability, and versatility. The design process involves considering various factors, including the intended use, building regulations, and safety standards.

Key considerations in the design include the geometry and arrangement of treads, risers, and stringers. The configuration of the staircase should provide a safe and efficient means of vertical circulation. Landings are essential for connecting stair flights and offering resting points for users. Structural engineers must account for dynamic loads caused by footfalls and other factors that can affect the staircase’s performance. Ensuring sufficient structural integrity to withstand accidental loading and to meet vibration serviceability criteria is crucial.

Proper connections to the primary structure are vital for ensuring stability and load-bearing capacity. The use of folded steel plates for treads and risers can enhance the staircase’s rigidity and dynamic response.

Summarily, the structural design of steel staircases requires careful planning, analysis, and adherence to building codes and safety regulations. By considering the specific requirements of each project, designers can create safe, efficient, and aesthetically pleasing staircases that meet the needs of users while enhancing the overall architectural design of the building.