Concrete mixer trucks have become indispensable in modern construction. These powerful vehicles not only enhance project efficiency. They also ensure high-quality results. If you’re involved in construction or just curious about how things get built so smoothly, you’re in the right place.

It is important to realise that the efficient mixing and transportation of concrete are critical operations on construction sites of all scales. The success and failure of some construction projects may depend on it. However, there are different methods of mixing and transporting concrete on site, and the crudest of them all is hand mixing and transportation using shovels, wheelbarrows, and headpans.

Practically, the selection of an appropriate method depends on the required volume of mixed material within a specified timeframe and the distances involved in horizontal and vertical transportation. Furthermore, the potential use of ready-mixed concrete should be carefully considered, particularly in cases where large volumes of concrete are needed and/or site space is constrained.

In this blog post, we’ll explore a concrete mixer truck’s vital role in contemporary construction. By the end, you’ll understand why these trucks are playing very important roles in the industry.

Ready-mixed Concrete and Concrete Mixer Trucks

The use of ready-mixed concrete has found wide applications in the construction industry. This has been so since 1968 when the British Ready-Mixed Concrete Association established minimum standards for plants, equipment, personnel, and quality control.

This industry now consumes a substantial portion of the United Kingdom’s total cement production, supplying millions of cubic meters of concrete annually to various regions. In the USA, it is largely controlled by the National Ready Mixed Concrete Association which was founded in the year 1930.

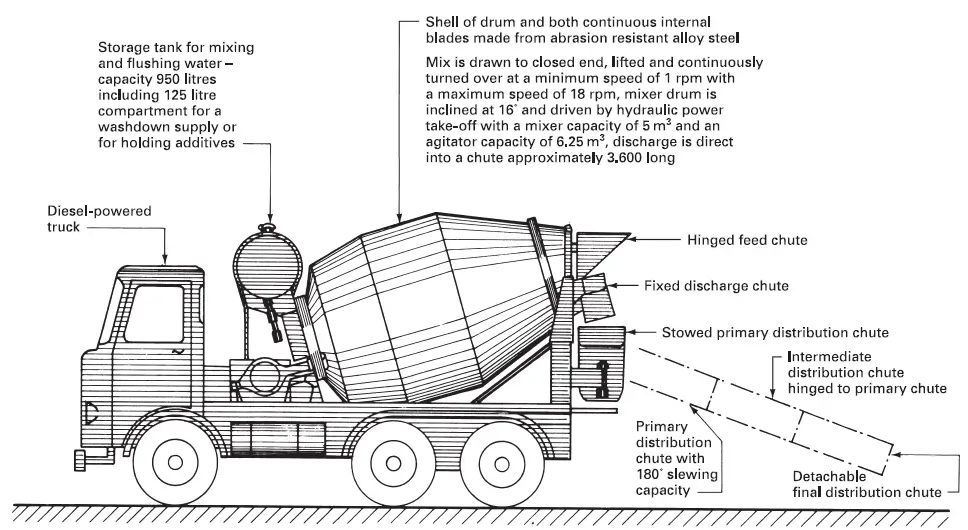

Ready-mixed concrete is delivered to construction sites in specialized concrete mixer trucks, which essentially consist of a mobile mixing drum mounted on a lorry chassis. These mixer trucks can be utilized in three primary ways:

(1) Complete Mixing at Depot: The truck mixer can be loaded at the depot with dry batched materials and water, allowing for complete mixing before leaving for the site. During transportation, the mix is kept agitated by the rotating drum. Upon arrival, the contents are remixed prior to discharge.

(2) Partial Mixing at Depot: The truck mixer can also be loaded with partially or fully mixed concrete at the depot. During transportation, the mix is agitated at a slower rate of 1 to 2 revolutions per minute. Upon arrival, the mix is finalized by increasing the drum’s revolutions to 10 to 15 revolutions per minute for a brief period before discharge.

(3) On-Site Mixing: When the location of the site is very far, timely delivery is critical, and the mixing process can be conducted entirely on-site. Dry batched materials are loaded into the truck mixer at the depot, and water is added upon arrival. The mixing operation is then completed, followed by discharge.

Acceptable Delivery Time of Ready Mixed Concrete

According to the previous British Standard BS 8500-2:2015+A2:2019, Clause 14.2, concrete transported in truck mixers or agitators was required to be delivered within two hours of loading. For non-agitating equipment, the delivery time was limited to one hour. These time constraints could be modified by the specifier, either shortening or extending them as needed.

However, it is important to note that the 2-hour transportation time limitation clause previously included in BS 8500 has been removed in the 2023 revision. This change is attributed to factors such as the introduction of new cement types, advancements in admixture technology, the adoption of modern computerized production plants, and improved mixer efficiency.

These developments have contributed to enhanced concrete placement without the unnecessary rejection of suitable concrete due to restrictive time constraints. However, the 2-hour guideline remains a reasonable benchmark for conventional concrete.

In recognition of the potential for concrete to retain its workability beyond a specific transit time, depending on factors like temperature, cement type, and admixture usage, ASTM C 94-21, Specification for Ready-Mixed Concrete, eliminated its 90-minute rule. This rule, established in 1935, required concrete discharge within 90 minutes of water introduction.

Through rigorous testing, the ASTM subcommittee validated that extending the discharge time to 150 minutes had no significant adverse effects on the concrete’s fresh properties, hardened properties, or durability. This revision aligns with the industry’s evolving understanding of concrete behaviour and allows for greater flexibility in transportation and placement.

Operation of Concrete Mixer Trucks

Truck mixers typically carry a water supply for cleaning the drum after concrete discharge and before returning to the depot.

As heavy vehicles weighing up to 24 tonnes when fully loaded, truck mixers require a firm surface and ample turning space on-site. A typical site allowance for unloading is 30 minutes, with 10 minutes allocated for discharge and 20 minutes for flexibility in planning and programming. Truck mixer capacities vary, but common sizes include 4, 5, and 6 cubic meters.

Contractors must carefully consider the best unloading position as most truck mixers have a maximum discharge height of 1.5 meters and a semicircular coverage radius of 3 meters around the rear of the vehicle using a discharging chute.

To fully leverage the benefits provided by ready-mixed concrete suppliers, building contractors must submit a clear order outlining their exact requirements. These specifications should adhere to the guidelines outlined in BS EN 206-1 and BS 8500-1 and 2.

The supply instructions should encompass the following:

- Cement Type: Specify the desired cement type.

- Aggregate Types and Sizes: Indicate the types and maximum sizes of aggregate required.

- Testing and Strength Requirements: Specify the desired testing methods and strength requirements.

- Testing Methods: Detail the preferred testing methods.

- Slump or Workability Requirements: Specify the desired slump or workability characteristics.

- Volume of Each Mix: Indicate the required volume of each separate concrete mix.

- Delivery Program: Outline the desired delivery schedule.

- Special Requirements: Specify any additional requirements, such as a pumpable mix.

To simplify the specification process, contractors can often specify the concrete grade (e.g., C30) and mix category (e.g., “Designed”). For more comprehensive details, refer to BS EN 206-1: Concrete. Specification, performance, production, and conformity and the complementary British Standards BS 8500-1: Concrete. Method of specifying and guidance for the specifier, and BS 8500-2: Concrete. Specification for constituent materials and concrete.

Types of Concrete Mixer Trucks

Transit Mixer: Designed for long-distance transportation of concrete.

Drum Mixer: The most common type, featuring a rotating drum to mix the concrete.

Twin-Shaft Mixer: Uses two shafts within the drum for more efficient mixing.

Advantages of Concrete Mixer Trucks

Efficient Concrete Mixing Process

The primary function of a concrete mixer truck is to mix and transport concrete from the batching plant to the construction site. This process reduces the time and manual labour required for mixing concrete on-site. Moreover, using a mixer truck ensures consistent mixing quality.

This is because the rotation of the drum churns the concrete. This prevents it from settling or separating. Take note that a high-strength concrete mix requires the right proportions of ingredients and thorough mixing. This can be achieved with a mixer truck.

On-Site Mobility and Versatility

Concrete mixer trucks are designed for on-site mobility. This makes them convenient and versatile in various construction scenarios. These trucks can access:

- difficult terrain

- narrow spaces

- high-rise buildings

Their compact size and manoeuvrability make it easier to transport concrete to many sites within a project. It goes the same with moving around obstacles on the construction site.

Time-Sensitive Delivery

One of the significant advantages of using a concrete mixer truck is its ability to deliver concrete on a tight schedule. Construction projects often have strict deadlines. And, delays can be costly. These trucks ensure the timely delivery of fresh and consistent concrete to meet project demands. This comes along with their efficient mixing process and on-site mobility. Plus, their large capacity allows for continuous pouring. Thus, reducing the need for frequent refills.

Large Volume Capacity

Concrete mixer trucks come in various sizes. They also come with an average capacity of 8-10 cubic yards. This large volume allows for the transport and pouring of concrete on a larger scale. Thus, making them ideal for commercial and industrial projects.

Moreover, volume capacity can be increased by attaching extra mixer drums to the truck. This makes it suitable for even bigger construction projects. This versatility makes concrete mixer trucks a valuable asset to the construction industry.

Consistent Quality Control

In construction, consistent quality control is essential. It helps ensure structural integrity and safety. Concrete mixer trucks help maintain this standard. This is achieved by mixing the concrete throughout transport.

This prevents any settling or separation of the concrete. Thus, resulting in a more uniform and stable mixture for construction purposes. It also reduces the risk of human error in the mixing process. Thus, helps with enhancing quality control.

If you check resources on Nationwide concrete mixer maintenance, for example — you’ll understand why it’s crucial to keep these trucks in top condition for consistent quality control.

Versatility in Mix Design

Different construction projects may need varying types of concrete mixtures. Concrete mixer trucks offer versatility in the mix design. This allows for different ingredients and proportions to be added while in transit.

This feature is especially useful when working on multiple construction projects that need different types of concrete. It also allows for adjustments to be made in case of changes or errors in the original mix design.

Especially if you are also using a portable concrete mixer, you can mix a small batch of specialized concrete on-site. This can be done without the need to transport it from a batching plant.

On-Site Mixing Capability

In some cases, construction projects may need on-site mixing due to project-specific needs. Concrete mixer trucks offer the flexibility to mix concrete on-site if necessary.

This feature is particularly beneficial for remote or hard-to-reach construction sites. This is when and where transporting pre-mixed concrete may not be feasible. It also allows for adjustments to be made in case of changes or errors in the original mix design.

Support for Continuous Pouring

Continuous pouring is essential in projects that require a large amount of concrete to be poured at once. This includes foundation or flooring work. Concrete mixer trucks support this process by providing a constant supply of fresh and consistent concrete.

These trucks can continuously pour for extended periods without the need for frequent breaks or refills. This comes along with their efficient mixing process and large volume capacity. This saves time and labor. Thus, making construction projects more efficient.

Reduction in Labor Costs

Using a concrete mixer truck can also lead to significant cost savings in terms of labour. These trucks eliminate the need for manual mixing on-site. This can be a time-consuming and physically demanding task.

Moreover, fewer workers are needed to handle the pouring process. This comes along with their large capacity and continuous pouring capabilities. This leads to a decrease in labour costs and allows resources to be allocated elsewhere within the project.

Adaptability to Various Project Sizes

Concrete mixer trucks can adapt to various project sizes. This is whether it’s a small residential project or a large-scale construction site. Their versatile design and functionality make them suitable for different types of construction projects.

From sidewalks and driveways to high-rise buildings and bridges, these trucks can handle a wide range of projects with ease. This adaptability makes them an invaluable tool for the construction industry.

Environmental Impact and Sustainability

Concrete mixer trucks have also made significant strides in reducing their environmental impact. Many companies now use eco-friendly fuel options for their trucks. This can include biodiesel or electric engines.

Advancements in technology have led to more efficient and cleaner operations. Thus, reducing emissions from these vehicles. This not only benefits the environment. It also helps construction companies adhere to strict environmental regulations.

Bottomline

A concrete mixer truck plays a vital role in modern construction by providing an efficient and versatile solution for mixing and transporting concrete. These trucks have revolutionized the construction industry. So next time you see a concrete mixer truck on the road or at a construction site, remember its important role in shaping our built environment.

To read more, you can visit our blog page. We do have more topics!