Household wastes are usually dumped in municipal solid waste landfills (MSWLFs). Landfills are sites that are designed for the dumping and management of municipal solid wastes. However, non-hazardous sludge, industrial solid waste, and construction and demolition waste can be dumped in landfills as well.

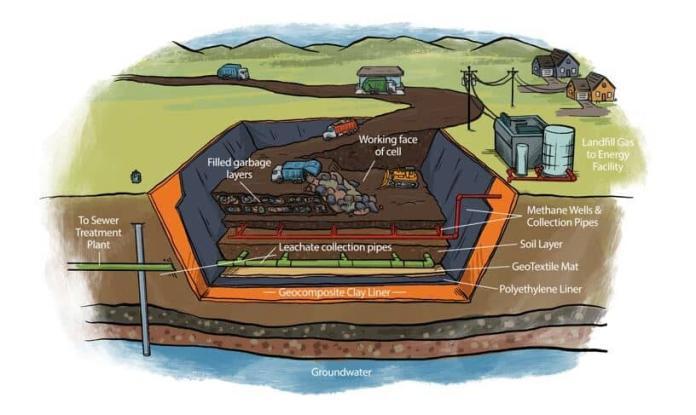

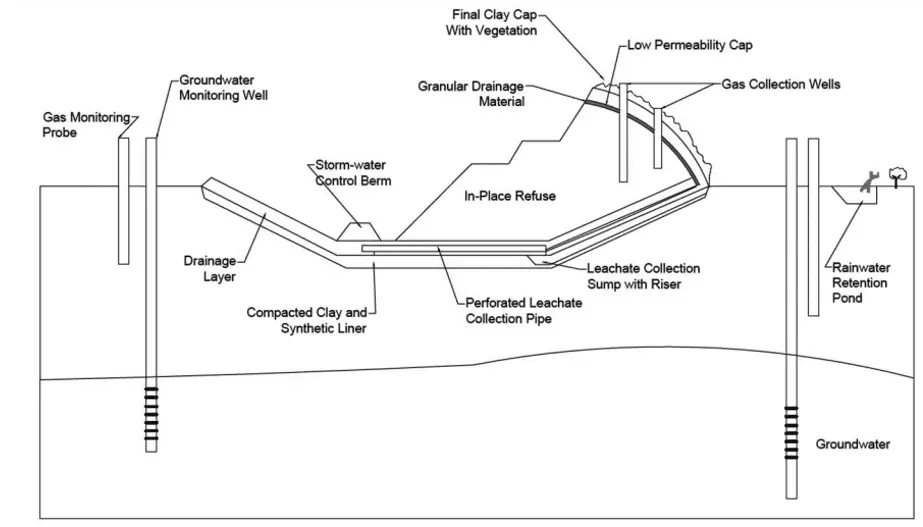

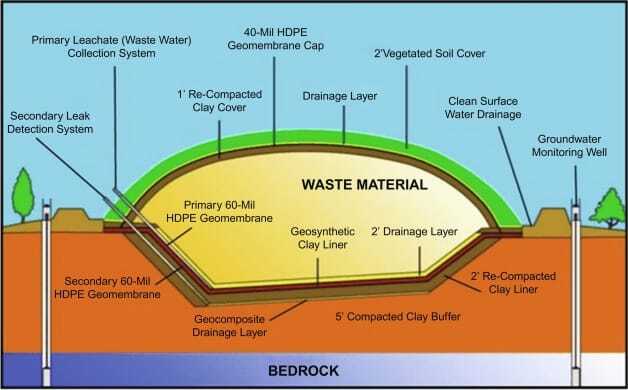

Modern landfills are well-engineered structures that are situated, developed, managed, and monitored to ensure they comply with the relevant environmental laws. The basic engineering design of landfills is to prevent the contamination of the ground and groundwater around the landfill. In essence, landfills for solid waste must be designed and constructed to safeguard the environment against contaminants that could be present in the waste stream.

Many of the concerns with landfills in the past were caused by poorly managed and improperly engineered dump sites. The disposal of waste in landfills has a lot of possible environmental consequences. The potential for groundwater and surface water pollution, the unchecked movement of landfill gas, and the generation of odour, noise, and visual nuisances are just a few of the long-term problems that may arise.

The dangers to human health resulting from the disposal of waste will be prevented, or at least reduced, to the greatest extent practicable, by proper landfill site design. It is important that the designer embrace practices, standards, and operational frameworks that are based on best practices currently in use and that take into account advancements in management practices and containment standards. The design approach should take into account the need to safeguard both human health and the environment.

Designing a landfill is a collaborative process that takes into account conceptual design ideas, results of environmental assessments and environmental monitoring, risk assessment, and findings from site investigations. Sustainable development is the main goal of waste management. Therefore, it is implied that landfill development and operation, which are inextricably intertwined, should take this strategy into account.

In addition to providing additional precautions, the landfill siting plan limits the placement of landfills in environmentally sensitive locations while on-site environmental monitoring systems look for any indication of groundwater pollution and landfill gas. Additionally, a lot of modern landfills capture potentially dangerous landfill gas emissions and turn them into electricity.

The main goal of landfill site design is to offer efficient control measures to prevent or reduce, as much as possible, adverse effects on the environment, in particular the contamination of surface water, groundwater, soil, and air, as well as the resulting risks to human health resulting from the landfilling of waste.

The soil properties, geology, and hydrogeology of the site, as well as any potential environmental effects, all affect a landfill’s architectural idea. A site-specific design should be able to be created with the help of the studies for a landfill.

The philosophy of landfill design has changed recently from the dry storage concept to the bioreactor approach. Leachate is recirculated in the bioreactor approach to increase the moisture content of the municipal solid waste and speed up biodegradation. This is a financially viable solution because it would be costly to dispose of collected leachate securely. By recirculating leachate, one can avoid the costly treatment cost of leachate.

In addition, waste degrades quickly as a result of the high moisture content brought on by leachate recirculation. Consequently, bioreactor landfills offer a significant decrease in post-closure management time and operation expense (Reddy and Bogner 2003).

A bioreactor landfill is described by SWANA (2001) as “any permitted landfill or landfill cell, subject to new source performance standards/emissions guidelines, where liquid or air, in addition to leachate and landfill gas condensate, is injected in a controlled manner into the waste mass to accelerate or enhance bio-stabilization of the waste.”

There are three different types of bioreactor landfills:

- anaerobic,

- aerobic, and

- hybrid.

In anaerobic bioreactor landfills, anaerobic microorganisms (those that do not need oxygen for cellular respiration) speed up biodegradation. These bacteria turn organic wastes into organic acids, which are then converted into methane and carbon dioxide (Sharma and Reddy 2004). Aerobic microorganisms, which need oxygen for biological respiration and create carbon dioxide, are used in aerobic bioreactor landfills. Hybrid bioreactor landfills combine the aforementioned two methods.

Types of Landfills

The Environment Protection Agency (EPA) reports that landfills are controlled under RCRA Subtitle D (solid waste) and Subtitle C (hazardous waste), or by the Toxic Substances Control Act (TSCA).

States and local governments are responsible for the principal planning, regulating, and implementing bodies for the management of nonhazardous solid waste, such as domestic waste and nonhazardous industrial solid waste (Subtitle D);

Subtitle D landfills include the following:

Municipal Solid Waste Landfills (MSWLFs) – Specifically designed to receive household waste, as well as other types of nonhazardous wastes.

Bioreactor Landfills – A type of MSWLF that operates to rapidly transform and degrade organic waste.

Industrial Waste Landfill – Designed to collect commercial and institutional waste (i.e. industrial waste), which is often a significant portion of solid waste, even in small cities and suburbs.

Construction and Demolition (C&D) Debris Landfill – A type of industrial waste landfill designed exclusively for construction and demolition materials, which consists of the debris generated during the construction, renovation and demolition of buildings, roads and bridges. C&D materials often contain bulky, heavy materials, such as concrete, wood, metals, glass and salvaged building components.

Coal Combustion Residual (CCR) landfills – An industrial waste landfill used to manage and dispose of coal combustion residuals (CCRs or coal ash). EPA established requirements for the disposal of CCR in landfills and published them in the Federal Register April 17, 2015.

Subtitle C establishes a federal program to manage hazardous wastes from cradle to grave. The objective of the Subtitle C program is to ensure that hazardous waste is handled in a manner that protects human health and the environment. To this end, there are Subtitle C regulations for the generation, transportation and treatment, storage or disposal of hazardous wastes. Subtitle C landfills including the following:

Hazardous Waste Landfills – Facilities used specifically for the disposal of hazardous waste. These landfills are not used for the disposal of solid waste.

Polychlorinated Biphenyl (PCB) landfills – PCBs are regulated by the Toxic Substances Control Act. While many PCB decontamination processes do not require EPA approval, some do require approval.

Design Considerations for Landfills

The designer should consider all environmental media that may be significantly impacted through the life of the landfill. The chosen design will have a major influence on the operation, restoration and aftercare of the facility. Aspects that must be considered in the design are briefly discussed below.

(1) Nature and quantities of waste

The waste types accepted at the landfill will dictate the control measures required. The requirements at a landfill accepting inert waste will be different to those at one accepting non-hazardous biodegradable waste which in turn will be different from a facility accepting hazardous waste.

(2) Water control

To reduce leachate generation, control measures may be required to minimise the quantity of precipitation, surface water and groundwater entering the landfilled waste. Contaminated water will need to be collected and treated prior to discharge.

(3) Protection of soil and water

A liner must be provided for the protection of soil, groundwater and surface water. The liner system may consist of a natural or artificially established mineral layer combined with a geosynthetic liner that must meet prescribed permeability and thickness requirements.

(4) Leachate management

An efficient leachate collection system may have to be provided to ensure that leachate accumulation at the base of the landfill is kept to a minimum. The leachate system may consist of a leachate collection layer with a pipe network to convey the leachate to a storage or treatment facility.

(5) Gas control

The accumulation and migration of landfill gas must be controlled. Landfill gas may need to be collected with subsequent treatment and utilisation, or disposal in a safe manner through flaring or venting.

(6) Environmental nuisances

Provisions should be incorporated in the design to minimise and control nuisances arising from the construction, operation, closure and aftercare phases of the landfill. Nuisances that may arise from landfilling include; noise, odours, dust, litter, birds, vermin and fires.

(7) Stability

Consideration must be given to the stability of the subgrade, the basal liner system, the waste mass and the capping system. The subgrade and the basal liner should be sufficiently stable to prevent excessive settlement or slippages. The hydraulic uplift pressure on the lining system due to groundwater must be considered. The method of waste emplacement should ensure stability of the waste mass against sliding and rotational failure. The capping system should be designed to ensure stability against sliding.

(8) Visual appearance and landscape

Consideration should be given to the visual appearance of the landform during operation and at termination of landfilling and its impact on the surrounding landforms.

(9) Operational and restoration requirements

The designer must consider the manner of site development and the necessary site infrastructural requirements during landfill operation and restoration. Landfill sites should be developed on a phased basis. Site infrastructure should include for the provision of; site accommodation, weighbridge, waste inspection area, wheelwash, site services and security fencing.

(10) Monitoring requirements

The designer should consider monitoring requirements at the design stage. These should be consistent with the requirements outlined in the Agency’s manual on ‘Landfill Monitoring’.

(11) Estimated cost of the facility

The designer should estimate the cost of the total project (construction, operation, closure and aftercare) from commencement to completion. This should include the costs of planning, site preparation and development works, operational works, restoration/capping works, landfill aftercare, and monitoring. Consideration should be given to the financing of the facility at the design stage in order to ensure that sufficient funds can be generated to fund ongoing and potential liabilities.

(12) Afteruse

The designer should consider the intended afteruse of the facility. It should be compatible with the material components and physical layout of the capping system, the surrounding landscape and current landuse zoning as specified in the relevant development plan.

(13) Construction

Environmental effects during construction must be considered. These may include noise from machinery, dust from soil excavation and soil placement, disturbance, traffic diversion, and avoidance of pollution by construction related activities.

(14) Risk Assessment

The design and engineering of a landfill should be supported by a comprehensive assessment of the risk of adverse environmental impacts or harm to human health resulting from the proposed development.

Conclusion

Modern landfills are well-engineered facilities which are situated, constructed, operated, and monitored in line with both federal and municipal laws. In the written word, there are three different kinds of landfills. Traditional dry landfills are the most popular choice. Dry landfills are being replaced by bioreactor landfills as a more environmentally friendly option. The newest entry on the list is sustainable landfills. Resources can be mined and refilled in sustainable landfills.

It is possible to think about landfills as a reliable and abundant source of materials and energy. This is widely recognized in the developing world, where waste pickers are frequently seen scouring the trash for useful stuff. Either landfilling is discouraged in underdeveloped nations or materials are recovered from landfills. In this framework, it is possible to see the idea of sustainable landfills as offering a universal remedy for waste disposal in both developed and developing countries.