In civil engineering works, excavation is the process of removing soil and rock from a designated area. It is an important aspect of building foundation construction or road works in most construction projects. Excavation works prepare the site for the construction of buildings, roads, utilities, basements, and various other structures.

The soil profile at a virgin construction site can be generally divided into:

(a) Topsoil (vegetable soil), and

(b) Subsoil

The topsoil of any virgin site is mineral in origin. However, it contains a very high proportion of organic matter as well as bacteria, insects and other creatures such as worms. As a result, they are not suitable for construction and are often removed, and discarded away from the site. Generally, the layer of topsoil is usually fairly uniform at around 200mm where the ground has been cultivated, down to around 100–150 mm for naturally occurring land with good vegetable growth.

The subsoil layer lies below and has no organic constituents in its makeup, although it might be home to living creatures that burrow below the topsoil. However, the subsoil is of interest to civil engineers and is usually used to support buildings, roads, bridges, towers, etc. Therefore, excavation works usually extend to the subsoil.

Many forget that excavations can be extremely dangerous and difficult jobs that can lead to huge complications if not done properly. Even though many underestimate its importance, you need some guidance on how to prepare for it and what to focus on in order not to encounter unnecessary problems. However, this is something you cannot avoid if you want to do any type of construction project. This article provides a step-by-step guide to help you go through this stage without any stress or worry.

Before the Commencement of Excavation

Before excavation commences, meticulous groundwork must be done on the site to ensure a seamless and efficient excavation. This preparatory phase encompasses several critical steps:

- Site Survey and Planning: A thorough site survey identifies underground utilities, potential hazards, site levels/topography and soil characteristics. This information guides the selection of the excavation method, and shoring systems (if needed), and determines the safe working depth. Plans outlining traffic management, stockpiling locations, and spoil removal routes are also established.

- Demolition and Clearing: Existing structures or vegetation within the excavation footprint may need to be removed. This could involve controlled demolition, careful tree removal, or surface clearing depending on the site conditions. Permit requirements and environmental considerations are addressed during this stage.

- Establishment of Datum and Site Levels: The establishment of the datum and site levels sets the reference points for all subsequent measurements, ensuring a structurally sound and level building. The datum, often referred to as a benchmark, acts as a fixed horizontal reference point with an assigned elevation. This elevation can be chosen arbitrarily or tied to a national survey network for larger projects.

Site levels are then determined relative to this datum. This is typically achieved using surveying instruments like levels and staffs to measure and mark out critical elevations on the site, such as finished floor levels, foundation depths, and column base heights. Establishing these reference points early on provides a consistent and precise foundation for the entire construction process. - Foundation Setting Out: Building setting out, also referred to as setting out or site layout is an important step in any construction project. It involves transferring the architectural plans and dimensions from paper to the actual building site. This process meticulously establishes the precise location and layout of the foundation, walls, columns, and other structural elements. They must be established before excavation work can commence.

Methods of Carrying out Excavation

There are different approaches to carrying out excavation works. However, it is important to point out that the chosen method depends on several factors such as the project scale, site conditions, soil type, and depth of excavation.

Project size and complexity: Larger projects often require mechanical excavation for efficiency, while smaller projects might utilize manual methods. If the extent to be excavated is very large, the manual method of excavation may become very tasking and time-consuming.

Site conditions: Soil type, presence of groundwater, and existing structures all influence the chosen technique. Hard rock necessitates specialized methods, while loose soil might be suitable for mechanical excavation.

Depth of excavation: Deeper excavations require more robust shoring systems and may influence the choice of equipment.

Cost and schedule: Balancing cost-effectiveness with project timelines is also an important factor to be considered.

Environmental regulations: Some methods, like trenchless excavation, might be preferred in environmentally sensitive areas.

Here’s a breakdown of common excavation techniques used in building construction:

1. Manual Excavation: Manual excavation is suitable for small-scale projects, or where there is limited space, or delicate work around existing structures. The process involves the use of hand tools like shovels, picks, and wheelbarrows for digging and transporting soil. It is cost-effective for small jobs and allows for more precise control in tight spaces. However, it is labour-intensive, slow, and limited to shallow depths due to safety concerns.

2. Mechanical Excavation: This category encompasses a variety of machines employed for faster and more efficient excavation on larger projects.

- Excavator: The most versatile machine, with a hydraulic arm and bucket for digging, loading trucks, and backfilling. Different-sized excavators are available for various project scales.

- Loader: Similar to a tractor with a front bucket, ideal for loading loose soil from the excavation pit into trucks or stockpiles.

- Bulldozer: Equipped with a large blade for pushing and levelling large amounts of soil, often used for initial site clearing or bulk excavation.

- Backhoe: Combines a digging bucket and a loading arm, making it suitable for trenching and smaller excavation jobs.

- Scrapper: A self-loading hauling machine with a scraper blade that excavates, transports, and dumps large quantities of earth over short distances.

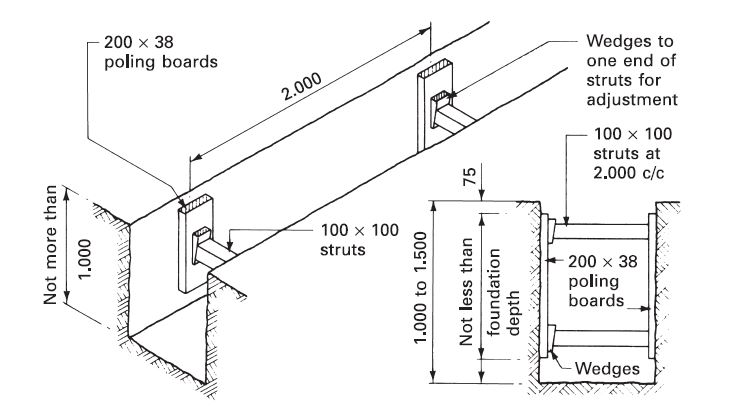

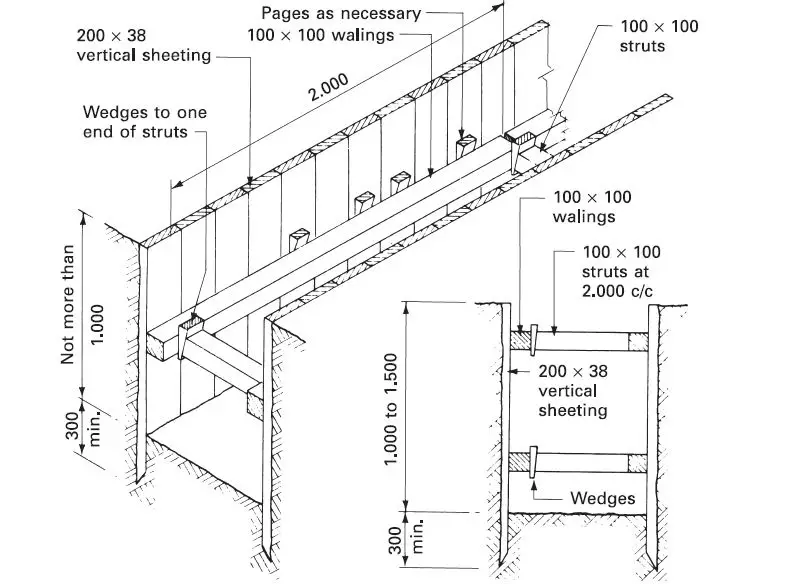

3. Trench Excavation: Trench excavation is when narrow strips of soil are excavated. It is suitable for installing underground utilities like pipes, cables, or conduits. The process typically involves digging a narrow, linear ditch using machinery or manual labour, depending on the depth and project scale. Shoring systems are often required to maintain trench stability and prevent cave-ins. Trenching is a high-risk activity, therefore proper shoring, maintaining a safe entry/exit angle, and having a rescue plan in place are crucial.

4. Basement Excavation: Basement excavation is carried out to create a basement level below the natural ground surface. The process requires digging a deep pit, often utilizing mechanical excavation equipment. Shoring techniques or the utilisation of braced cuts like sheet piles, soldier piles, or lagging are frequently used to ensure the stability of surrounding structures and prevent soil collapse.

Alternatively, the sides of the excavation may be sloped to increase the stability.

5. Rock Excavation: Rock excavation is suitable for sites with hard rock formations that cannot be removed with conventional machinery. Specialized techniques like blasting or mechanical rock breaking with hydraulic hammers mounted on excavators are employed. Blasting requires careful planning and execution to minimize risks and comply with local regulations.

6. Trenchless Excavation: Trenchless excavation is employed when there is a need to minimise surface disruption, or when working under existing structures or environmentally sensitive areas. Various methods exist for trenchless excavation such as horizontal directional drilling (HDD), pipe bursting, and vacuum excavation. These techniques utilize specialized equipment to create underground passages without traditional open excavation.

Timbering/Shoring Foundation Excavations

Timbering or shoring is a term used to cover temporary supports to the sides of excavations and is sometimes called planking and strutting. For deep excavations, appropriately designed braced cuts will be required. In a construction site, timbering or shoring constitutes the temporary works of the project.

In clay or cohesive soils, vertical excavations can be self-supporting up to a depth known as the critical depth. The excavation is at risk of collapse once the depth of the excavation exceeds the critical depth. The critical depth depends on the shear strength and unit weight of the soil.

Generically, the sides of some excavations will need support to:

- protect the operatives while working in the excavation;

- keep the excavation open by acting as a retaining wall to the sides of the trench.

The type and amount of timbering required will depend upon the depth and nature of the subsoil. Over a short period, many soils may not require any timbering, but weather conditions, seepage, depth, type of soil and duration of the operations must all be taken into account, and each excavation must be assessed separately.

Simplified Guide to Successful Excavation Works

The following simplified checks must be carried out to ensure a hitch-free excavation programme.

Soil Testing and Site Plan

Before doing anything else, make sure the soil is appropriate for the kind of construction you want to build there. This can be accomplished through rigorous site investigation and laboratory testing of soils. Keep in mind that soil can differ very much and that small negligence can lead to catastrophic results. When it comes to site planning and site surveying, always hire a professional to make sure everything is safe and that the topographical and geotechnical survey is reliable.

Qualified Operators

Always search for qualified operators to make sure everything is in order and to ensure they know what they are doing. Every operator needs to have something to prove their qualifications. For example, Excavator tickets Sydney are very important, as you need to go through some training to see whether you are actually able to perform such a job. This proof is necessary to know whether they are reliable or not and not to worry about any complications.

Necessary Permits

Many people make this mistake and start the excavation without actually making sure they have all the necessary permits and encounter delays and legal problems. These rules differ from place to place, but everywhere you need to submit the required documentation and plans to obtain an excavation permit. Once you do this, you don’t have to worry about any unnecessary legal complications and can continue without stressing out about it.

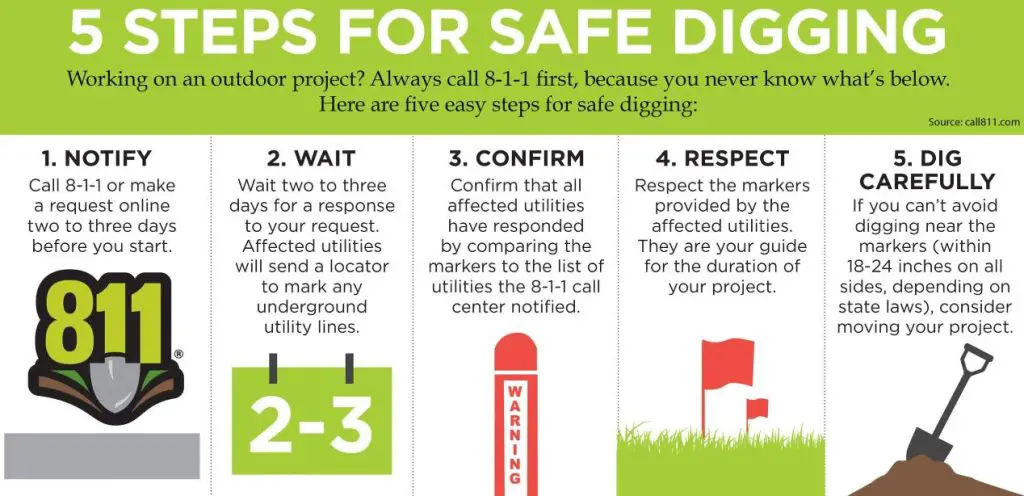

Inform Public Utilities (Call Before You Dig)

This is also very important, as this way you can prevent any damage to underground utilities. Always contact them before you start any work and request that they mark the location of the underground lines that you can later use to plan the whole process without causing any problems.

“Call Before You Dig” is a national program in the United States (and many other countries have similar initiatives) aimed at preventing underground utility line strikes during excavation projects. Before any excavation work, regardless of size or depth, property owners or contractors are required to contact a one-call centre in their area, typically by dialling the national number 811. This call initiates a process where the location of underground utilities (gas lines, electrical lines, water lines, etc.) within the designated excavation area will be marked by professional locators.

This service aims to safeguard people and property by promoting awareness of underground utilities before any digging commences. Striking a buried utility line can cause serious injuries, property damage, and service disruptions.

Focus on Safety

Once you have gone through all these steps and have made sure everything is ready for the excavation, make sure to implement safety measures at the excavation site to protect people from any injuries caused by improper signs. This way, you also keep any unauthorized people off the construction site, managing the safety of someone who doesn’t know how unsafe this can be. Also, always ensure the workers wear all the required safety pieces of equipment to avoid any tragic problems.

Bottomline

Excavation is not as simple as it seems and demands careful planning and operation. With the help of this article, you know what you have to do to ensure the safety of both the workers and everyone around you and to make sure you follow all the legal obligations in order to avoid additional problems and shorten this whole process.