Reinforcements in concrete piles are usually provided to counteract the bending and tensile stresses that are developed during the installation or working life of the pile foundation. Pile foundations are deep foundations that are in the form of slender columns used for transmitting superstructure loads to deeper stratum in the soil. Pile foundations derive their load-bearing capacity from side friction, end-bearing, or both.

While reinforcement in concrete piles can contribute to compression load-bearing, its extent at any pile section is determined by the specific loads and stresses applied. The extent of pile reinforcement is determined by specific needs and requirements, which vary based on individual projects.

There is no definitive standard for the location (depth of embedment) or quantity of reinforcement. Generically, pile analysis theories, incorporating field observations and theoretical considerations, provide the necessary guidance for determining the quantity and extent of reinforcement required in the pile.

Pile foundations that are subjected to bending moments require reinforcement, and the Matlock and Reese method (1960) provides a means to evaluate bending moments and shearing forces in laterally loaded piles. This approach models the pile as an elastic beam embedded in a homogeneous or nonhomogeneous soil. The ultimate capacity of a laterally-loaded pile is often governed by the structural capacity of the pile’s flexible length.

Types of Reinforcement in Piles

The two main types of steel reinforcement found in concrete piles are longitudinal and lateral reinforcement.

- Longitudinal Reinforcement: This consists of steel bars or wires running parallel to the pile’s length. It is primarily responsible for resisting axial forces, such as compression and tension.

- Lateral Reinforcement: Also known as transverse reinforcement, this comprises steel stirrups or ties that encircle the longitudinal bars. It is essential for resisting shear forces, which can occur due to lateral loads or seismic activity.

Structural Behaviour of Piles

The structural behaviour of piles may depend on whether some portion of the pile extends above the grade level or whether the pile is fully embedded in the ground. The properties or stiffness of the soil surrounding the pile may also influence its properties.

Piles fully embedded in the ground

According to IS 2911-1-1 (2010), when an axially loaded pile is fully embedded in soil with a minimum undrained shear strength of 10 kN/m², its axial load-carrying capacity is not necessarily restricted by its structural capacity as a long, slender column.

However, for piles installed in very soft soils with an undrained shear strength below 10 kN/m², additional analysis is required to assess the potential for column buckling. If buckling is a concern, appropriate reductions to the pile’s structural capacity should be applied based on standard structural engineering principles.

Research has shown that soil cohesion exerts a substantial influence on the stress distribution along the length of a pile. As soil cohesion increases, leading to greater soil stiffness, compressive stresses within the pile tend to increase.

In the case of soft soils characterized by low cohesion, tensile stresses are likely to be present within the pile at a depth approximately six times the pile diameter. Subsequently, at a depth of roughly twelve times the diameter, stresses may return to zero. Beyond this depth, compressive stresses are typically observed.

Piles above the ground Level

When a pile extends above ground level without adequate bracing, its effective length, which influences its buckling resistance, is determined by factors such as:

- Structural Connections: The way the pile is connected to the superstructure.

- Soil Conditions: The type and strength of the soil surrounding the pile.

In good soils, the point of contraflexure can be assumed to be approximately 1 metre below ground level, but not less than three times the pile diameter. In weak soils like soft clay or silt, the point of contraflexure may be located at about half the pile’s penetration depth into the weak stratum, up to a maximum of 3 meters or 10 times the pile diameter, whichever is greater.

According to BS 8004, vertically driven piles that are fully embedded in the ground usually have a low risk of buckling. Therefore, it’s not necessary to apply column design principles outlined in various design standards.

However, for exceptionally long and slender piles installed in very soft soils (such as alluvial soils with a shear strength of less than 20 kN/m²), additional considerations are necessary. However, when a portion of the pile extends above ground level, that part should be designed as a column following the guidelines of reinforced concrete design standards. The points of contraflexure requirements are the same as those found in IS 2911-1-1 (2010).

Reinforcement Requirements in Cast-in-situ Concrete Piles

The magnitude of applied loads, type of soil, and structural design considerations determine the quantity and extent of reinforcement required for cast-in-situ concrete piles. While some building codes (such as BS 8004 – 1986 and DIN 4014 -part I-1975) provide distinct reinforcement guidelines for driven and bored piles, others (like IS 2911-1-1:2010 and ACI 543R-1974)) treat both types under a unified framework for cast-in-situ concrete piles.

IS 2911-1-1(2010) provides the following recommendations for reinforcement in cast-in-situ concrete piles:

- Cage Construction: Reinforcement should be formed into cages that are securely wired to maintain their shape during handling and installation.

- Bar Spacing: Bars should be spaced adequately to allow for proper concrete placement and consolidation.

- Lateral Ties or Spirals: Lateral ties or spirals should be spaced at a minimum of 150 mm centre-to-centre.

- Reinforcement Percentage: The total reinforcement percentage should generally not exceed 0.8% of the pile’s cross-sectional area.

ACI 543R (2000) provides recommendations for reinforcement in cast-in-situ concrete piles in the following situations:

- Unsupported Sections: For any portion of the pile that is not fully embedded in solid ground (e.g., sections through air, water, or very soft soil), reinforcement is necessary to resist buckling under applied loads.

- Uplift Loads: If the pile is subjected to upward forces, reinforcement is required to counteract tensile stresses.

- Lateral Loads: When lateral forces are present, the pile should be designed and reinforced to resist the resulting bending moments and shear forces.

General Reinforcement Guidelines:

- Minimum Longitudinal Reinforcement: A minimum of four longitudinal bars is recommended, except for cases involving only uplift loads.

- Reinforcement Extent: The amount and distribution of reinforcement below ground level should be determined based on structural analysis considering flexural stresses and load distribution.

Overall, the extent of reinforcement in cast-in-situ concrete piles is primarily governed by the specific loading conditions and structural analysis results.

DIN 4014 (1990) recommends that bored piles typically require both longitudinal and transverse reinforcement along their entire length. The minimum diameter of the longitudinal reinforcing bars shall be 16 mm, while the minimum diameter of the links shall be 6 mm, with a maximum spacing (pitch) of 250 mm.

This reinforcement is usually formed into a cage and installed within the casing pipe to prevent displacement during concreting or extraction of the casing. The spacing of the reinforcing bars shall not be less than twice the maximum size of the aggregates. Clear cover to reinforcement shall not be less than 50 mm.

In certain cases, full-length reinforcement can be omitted for vertical piles with a diameter of at least 30 cm and a length of no more than 7.5 m, provided there’s no risk of bending due to earth pressure, lateral pressure from soft soils, eccentric loading, or other factors.

Curtailment of reinforcement along the depth of the pile

As stated earlier, the extent to which reinforcement within a pile can be curtailed typically varies depending on the specific loading conditions and the nature of the underlying soil.

In the design of cast-in-situ bored piles, building codes do not explicitly stipulate a specific depth for reinforcement bars to counteract tensile stresses. This design aspect is typically left to the discretion of the engineer.

For piles subjected solely to compressive loads, the amount of reinforcement may be curtailed at suitable depths as determined by the design specifications. For bored piles in sand, the reinforcement should extend to at least 0.4 times the length of the pile.

The reinforcement requirements for bored piles in clay are primarily determined by the shear strength of the soil. In stiff clay, the reinforcement may be curtailed at the top quarter to ensure adequate anchorage with the pile cap. However, in soft clays, the reinforcement length may need to extend beyond half the pile length.

However, for piles experiencing uplift loads, lateral loads, bending moments, or a combination of these with compressive loads, reinforcement must be maintained throughout the entire pile length.

Furthermore, in instances involving soft clay, loose sand, or situations where the integrity of the fresh concrete may be compromised by the driving of nearby piles, reinforcement should be provided along the full depth of the pile, irrespective of the requirements arising from uplift or lateral load considerations.

According to Bowles (1988), reinforcement in bored piles may be primarily necessary in the upper regions. This is because bending moments, which are resisted by the pile shaft, tend to reduce with increasing depth. Consequently, the primary load carried by the shaft at approximately half its length (L/2) is axial. Furthermore, temperature fluctuations at this depth are generally minimal, thus negating the need for longitudinal and spiral reinforcement.

Tomlinson and Woodward (2008) also suggest that reinforcement in bored piles might not be essential unless the pile is subjected to uplift forces. These uplift forces can arise from the swelling and shrinkage of clay soils. Additionally, reinforcement may be required in the upper portion of the shaft to withstand bending moments resulting from eccentric loading or moments transferred from ground beams.

Effect of Bending Moment

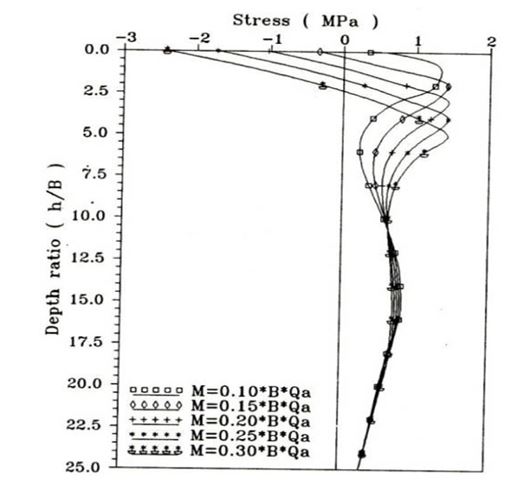

Salman et al. (2010) showed that for bored piles in clay, tensile stresses are primarily concentrated in the upper portion of the pile shaft due to applied bending moments. As depth increases, these tensile stresses gradually diminish and transition into compressive stresses. The maximum tensile stress coincides with the point of maximum bending moment.

Theoretical analyses suggest that at a depth ratio of approximately 2.5 times the pile diameter, the tensile stress becomes negligible and subsequently transitions to compressive stress. This observation implies that reinforcement may only be necessary up to this depth to counteract the tensile stresses.

Effect of Lateral Loading

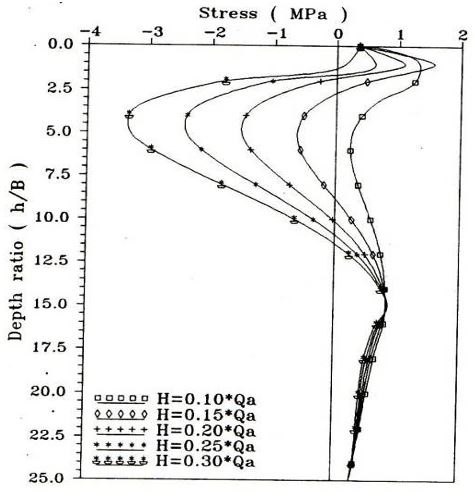

According to Salman et al. (2010), as the applied lateral load on a bored pile in clay increases, the tensile stress within the pile decreases. This inverse relationship is likely due to the increased soil resistance counteracting the bending moment caused by the lateral load. The depth at which tensile stress becomes zero also increases with increasing lateral load. This implies that the zone of tensile stress shifts deeper into the soil as the lateral load intensifies.

The maximum tensile stress typically occurs at a depth ratio between 4 and 6, depending on the lateral load magnitude. A higher lateral load generally corresponds to a deeper location of maximum tensile stress. For a lateral load of 30% of the applied load, the zero tensile stress occurs at a depth ratio of approximately 11.5. The effect of the applied moment becomes negligible at a depth ratio of about 10, while the influence of the lateral load itself diminishes at a depth ratio of around 15.

Conclusion

Curtailment of reinforcement in piles is a design consideration that aims to optimize the use of steel while ensuring structural integrity. The extent of curtailment depends primarily on the type of loading (compressive, uplift, lateral), soil conditions (stiffness, cohesion), and the presence of bending moments.

For piles under compressive loads, reinforcement can be reduced at appropriate depths according to design requirements. However, in cases involving uplift, lateral loads, or moments, full-depth reinforcement is generally necessary. Additionally, in soft soils or when adjacent pile driving poses a risk to fresh concrete, full-depth reinforcement is recommended regardless of specific loading conditions.

Sources and Citations

ACI Committee 543R (1974). Recommendations for Design, Manufacture, and Installation of Concrete Piles. (ACI 543R, 74), American Concrete Institute.

Bowles JE (1988). Foundation Analysis and Design. 4th edition. McGraw-Hill Book Company.

DIN 4026 (1975). Driven Piles, Manufacture, Dimensioning, and Permissible Loading.

DIN 4014 (Part-I) (1975). Bored Piles for Conventional Type, Manufacture, Design, and Permissible Loading.

Matlock H, Reese LC (1960). Generalized solutions for laterally loaded piles. JSMFE. ASCE, 86(SM5): 63-91.

Salman F.A., Fattah M.Y., Mohammed M. M. and Hashim R. (2010). Numerical investigation on reinforcement requirement for piles embedded in clay. Scientific Research and Essays Vol. 5(18), pp. 2731-2741

Tomlinson M, Woodward J (2008). Pile Design and Construction Practice. 5th edition. Taylor and Francis. New York.