Concrete joints are essential components of various structures and are implemented on construction sites based on specific construction requirements and design considerations. Construction joints in concrete structures are almost unavoidable, given that structures cannot be built in a single casting step. Therefore, with the presence of joints, building the structure piece by piece is possible until it becomes a complete whole.

There are different types of joints in concrete such as movement joints, contraction joints, expansion joints, sliding joints, construction joints, temporary joints, and isolation joints. Some of these joints can exist in structures of different configurations, addressing specific technical needs based on the design and nature of the structure.

Construction Joints

Construction joints are deliberate separations or discontinuities created within concrete structures. In other words, construction joints allow for the placement of concrete in stages. This is because it is not practical to pour concrete for an entire structure in a continuous manner, except for small construction works.

For example, depending on the technical capacity of the contractors, it may not be feasible to pour the concrete of a floor and the continuation columns of the floor on the same day. Moreover, the maximum quantity of concrete that may be mixed and placed on the construction site is also determined by the batching and mixing capacity, the number of the workforce, and the allocated time duration.

In effect, accurately positioned and effectively implemented construction joints establish boundaries for consecutive concrete placements, without causing any negative impact on the structure. A properly constructed joint in monolithic concrete ensures a robust and watertight surface, allowing the joint to maintain its flexural and shear continuity. In the absence of this continuity, the region becomes weaker, potentially functioning as a joint for either contraction or expansion.

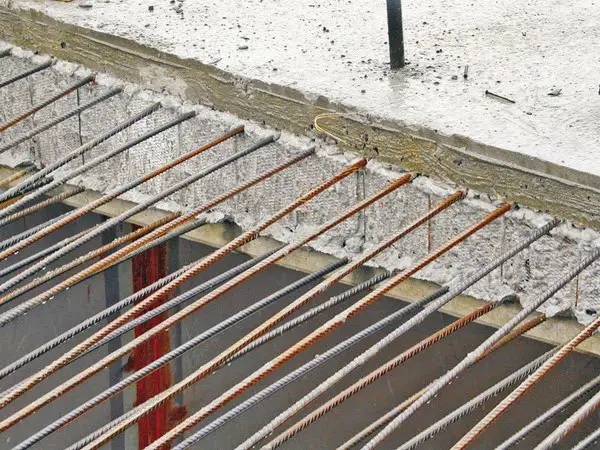

Preparation of Construction Joint Surfaces

To establish a strong and impermeable joint, several prerequisites must be met before the application of the newly poured concrete. It is necessary for the concrete to be thoroughly cleaned and free of any laitance residue.

When there is a short period of time between consecutive placements, it is essential to visually inspect and ensure that any loose particles, dirt, and laitance have been thoroughly removed. To ensure proper bonding between the new concrete and the hardened concrete, the new concrete should be extensively vibrated throughout the entire area.

For more mature joints, additional surface preparation is required. The concrete can be cleaned using an air-water jet or wire brooming while it is in a state where the laitance can be removed but the aggregate remains securely in place. To prepare hardened concrete, it is recommended to use either a wet sandblast or an ultra-high-pressure water jet, as stated by the ACI Committee 311 (2019).

According to ACI 318, it is necessary to thoroughly dampen the existing concrete before placing fresh concrete. Green concrete does not require any more water, but concrete that has dried up may require saturation for a duration of one day or longer. During concrete placement, there should be no stagnant water on the wet surface.

Location of the joint

When designing construction joints, it is important to consider the precise placement or location of the joint in the structure. If construction capacity allows, construction joints should be positioned in a way that minimizes the impact on the structural strength of the structure while still being in harmony with the building’s aesthetics.

The positioning of joints varies depending on the nature of the element being constructed. To provide clarity, beams and slabs will be discussed as distinct entities from columns and walls.

Beams and slabs

When it comes to the structural integrity of beam and slab floor systems, it is recommended to position joints perpendicular to the main reinforcement at sites where shear is minimal or at points of contraflexure. At the point of contraflexure, the bending moment is expected to be very minimal. Therefore, it is going to be the least stressed section of the structure.

Typically, joints are placed at the midpoint or within the central third of the span, but their exact placement should be confirmed by the structural engineer. According to ACI 318, in beam and girder construction, when a beam crosses a girder at the place where the shear is minimal, the construction joint in the girder should be positioned at a distance that is twice the width of the incident beam.

It is often discouraged to use horizontal construction joints in beams and girders. A conventional approach involves integrating beams and girders seamlessly with the slab. To achieve flexural continuity, it is necessary to extend the reinforcement through the joint with a length that is sufficient to provide an appropriate splice length for the reinforcement. Shear transmission occurs through either shear friction between the existing and new concrete, or dowel action in the reinforcement across the joint.

In Nigeria, it is usually typical to cast the beams of a suspended floor first, when it is not feasible to cast the entire floor in a single pour. At the subsequent casting, the slab deck is poured to sit on the hardened beam.

Columns and Walls

When it comes to concrete placement, it is common practice to limit the height of concrete to one story. Construction joints in columns and bearing walls should be positioned at the lower surfaces of floor slabs and beams, and at the upper surface of floor slabs for columns that extend to the subsequent floor. The column capitals, haunches, drop panels, and brackets must be integrated seamlessly with the slab.

The positioning of newly poured concrete on a level surface can impact the connection point. Traditionally, it is customary to apply a layer of mortar, with the same proportions as the concrete, before pouring new concrete over the joint. The ACI Manual of Concrete Inspection (ACI Committee 311, 2019) recommends using a bedding layer of concrete that contains a slightly higher proportion of cement, sand, and water than the design mix specified for the project.

Material measuring less than 3/4 inch can remain in the bedding layer, whereas any material above 3/4 inch should be removed. The recommended depth for placing this mixture is between 4 to 6 inches, and it should be vibrated vigorously along with the standard mixture placed on top.

Conclusion

Construction joints play a crucial role in the performance and buildability of reinforced concrete structures. They serve as specially selected interfaces between different sections or phases of a structure, during the concrete pour. Construction joints are typically formed by placing a layer of concrete, then allowing it to set before placing the next layer. The joint is then formed by removing any loose material and cleaning the surface of the concrete.

It is important to ensure that there is continuity of reinforcements at construction joints to ensure maximal shear transfer between the joints. Furthermore, in flexural members, joints should be located where stresses are minimal, while in compression members such as columns and walls, they should be preferably located at the top and bottom of the members.

Construction joints are crucial elements in ensuring the structural integrity, constructability, and aesthetics of concrete structures. Understanding their types, design considerations, and benefits helps optimize their role in creating safe, durable, and visually appealing buildings.