In Nigeria, duplexes are the most preferred choice for private residential building construction. Duplexes normally consist of a ground floor and one suspended reinforced concrete floor with a living room (sitting room/parlour), en-suite bedrooms, dining room, kitchen, lounges, and other spaces as may be desired. Lobbies are used to connect the spaces in a duplex building, and a staircase is used for vertical circulation. Residential buildings with more than one suspended floor should not be described as duplexes.

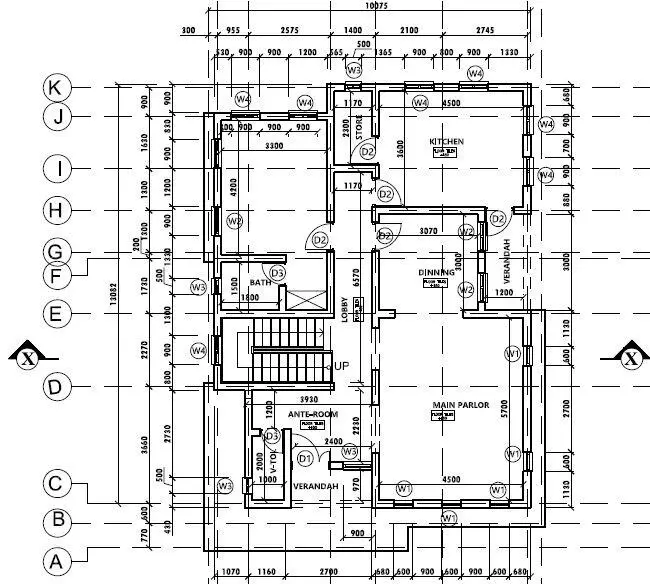

In most duplex designs, it is very typical for the living room, dining, kitchen, laundry room, and storeroom to be on the ground floor. The living room may be double volume (with no reinforced concrete slab over it), or it can be covered with a reinforced concrete slab to create more spaces upstairs.

The former alternative is usually for aesthetics and gives a sense of a freer atmosphere in the living room. Furthermore, it reduces the cost of construction due to the void over the sitting room, however, this comes at the expense of the loss of potentially useful space on the first floor.

The ground floor of most duplexes in Nigeria also houses the ante-room, visitor’s toilet, and the visitor’s bedroom which is usually provided with its own convenience (en-suite with toilet and bathroom). Depending on the desire of the client or homeowner, additional bedrooms and facilities may be provided on the ground floor. While this is usually very applicable to moderate duplexes, luxury duplexes can considerably vary in arrangement.

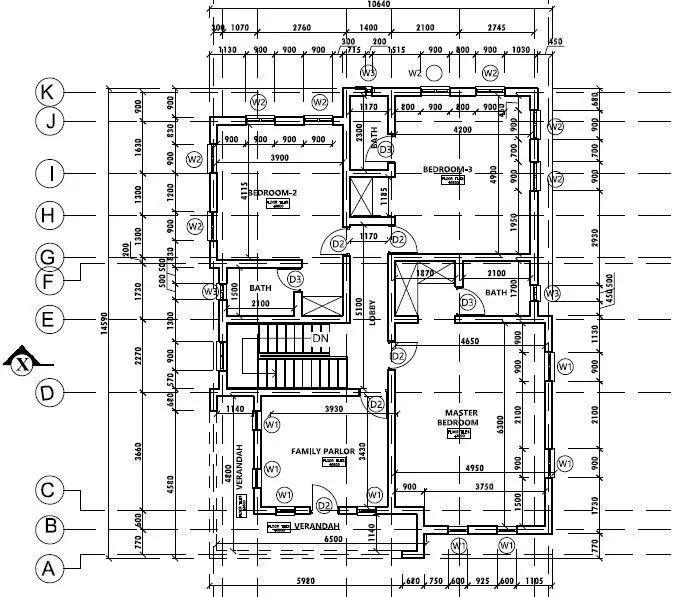

The first floor of a moderate duplex usually contains the majority of the bedrooms. A private family lounge can be provided on the first floor with a kitchenette that can serve as a coffee room. In modern construction, all the bedrooms should be en-suite.

Luxury duplexes can contain additional spaces such as exclusive wine cellars, study rooms/private offices, gyms, saunas, library rooms, theatres/cinemas, games rooms, bigger walk-in closets, kids’ play area, exclusive pantry rooms, elevator, panic room, mechanical/electrical panel rooms, internet server rooms, indoor swimming pool, etc. Modern luxury apartments should be smart buildings with most of the facilities fully automated.

The cost of constructing a duplex building in Nigeria depends on a number of factors such as;

Size: The size of the building will significantly increase the cost of materials and labour needed to construct the building. The bigger the building, the bigger the cost of execution.

Type of land: Buildings that are founded on soft/weak soils will cost considerably more than buildings that are founded on stiff non-problematic soils. Also, the effects of the depth groundwater table can influence the cost of construction. Duplex buildings on marginal soils can be supported on a raft or pile foundation, while duplexes on good soils can be supported on pad foundations. Buildings on pad foundations are cheaper than buildings supported on a raft or pile foundation.

Read Also…

The Cost and Processes of Constructing a Raft Foundation in Nigeria

Method of Construction: The construction method you choose might have a big impact on the cost of your building project. Before installing the block walls and partitions, contractors can build the structural parts of duplexes as pure reinforced concrete frames consisting of beams, columns, slabs, and staircases.

On the other hand, the partition walls and the structural frames can be constructed simultaneously, an approach that is more common in low- to medium-budget duplex construction projects. The latter has the advantage of being faster while saving a significant amount of money on materials and labor. The former, however, is of higher quality due to more stringent quality control throughout the construction of the structural elements.

Location of the project: The cost of a project can also be influenced by its location. Sites that are close to sand and gravel supplies will have lower material costs than sites that are further away. Additionally, if the site is not accessible by truck, significant labour expenditures will be incurred in transloading the items into your site before they are used. Labour costs can also be a factor since the average cost of labour varies from location to location.

Taste of the client: While the cost of constructing the frames and carcass of a duplex should be relatively consistent among buildings of similar size and volume, the cost of finishing a duplex might vary significantly because of the wide range of alternatives available to clients. A building’s finishes might be either high-end or low-cost. This can include everything from roofing sheets to doors, windows, tiles, sanitary fittings, electrical fittings, painting, among other things. A homeowner can choose between the cheapest choice and the most expensive luxury option. The price difference can be as much as 500%.

Getting Started in Duplex Construction

Land Acquisition

As should be expected, the first step in the construction of a duplex should be the acquisition of land. In the villages or rural areas, family or communal lands can be conveniently obtained depending on the family agreements. In the towns of Nigeria, landed properties can be purchased from individuals, corporate bodies, or real estate firms.

In all cases, the land to be used for the construction should be properly surveyed by a registered surveyor, and the title of the land clearly defined. The land should be properly registered and all legal documents for ownership properly verified. All laws for property ownership in the state should be fulfilled by the client.

Architectural Design

After you have secured your plot of land for the proposed construction, the design of the building can commence. The architect designs your preferred building while also satisfying the local building regulation codes/requirements, taking into account the nature, size, and shape of your site.

The airspace and setbacks between the property lines and the building line should adhere to the local building code. Septic tanks, soakaway pits, boreholes, gatehouses, generator houses, outdoor swimming pools, and other structures should all be clearly mapped out on the site layout.

Civil Engineering Designs

The geotechnical and structural engineering designs should be carried out for the ultimate safety of the proposed building. Site investigation and sub-surface exploration should be carried out to determine the engineering properties of the sub-surface soils. This information will inform the type of foundation to be used for the duplex. At the initial stage, a cue should be taken from the type of foundation used for supporting the surrounding buildings if any.

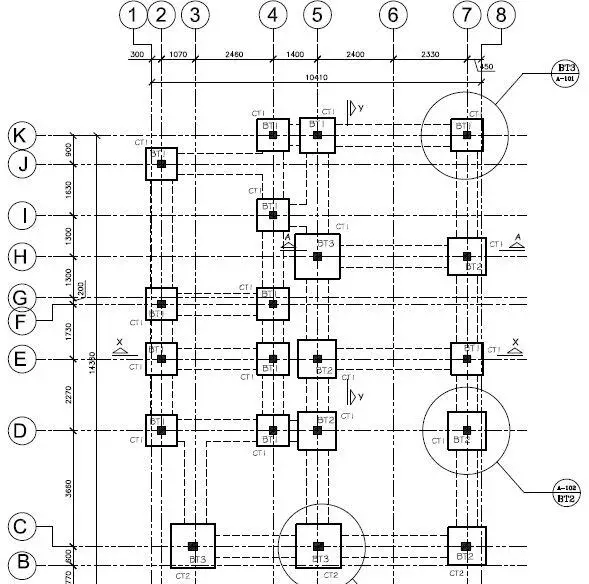

A structural design will identify the location and design of the columns, beams, slabs, staircase, and foundation. The structural design should be carried out, checked, and sealed by a COREN-registered civil engineer. A letter of structural stability and supervision should also be issued to you by the structural engineer.

Mechanical and Electrical Designs

The mechanical design should include the building’s plumbing, HVAC, and water sprinkler systems, among other things. The design should be in harmony with the building’s architectural and structural design so that the route of pipes, ducts, and other utilities can be clearly specified during the design stage, to avoid chiselling of structural components after construction.

The arrangement of electrical pipes and light fittings, security cameras, alarm systems, internet and television cables, cable tray routes, the position of distribution boards/panels, and so on should all be included in the electrical designs. COREN-registered mechanical and electrical engineers shall design and stamp the services drawing.

Approval

Having obtained all the necessary drawings, the complete set of drawings comprising the architectural, structural, mechanical, electrical, and soil test report should be submitted to the Physical Planning Board/Agency of the locality for approval. Other documents as may be required should be submitted too. Once the drawings are approved, the construction can commence.

Cost of Constructing a Duplex in Nigeria

For the sake of convenience in costing and project management, duplex construction in Nigeria can be conveniently broken into the following stages;

- Substructure (foundation)

- Ground floor to overhead level

- First-floor decking

- First floor to roof overhead level

- Parapet and roofing

- Finishes

These stages are consistent with projects where the block walls and the frames are to be built up together. For buildings that are to be constructed as pure frame structures, the above breakdown will not be very adequate.

Let us now survey the cost of constructing each phase of a duplex using the four-bedroom duplex building plan below as a case study. The building is to be constructed in a semi-urban region in south-eastern Nigeria, on lateritic soil with a bearing capacity of 175 kN/m2 at a depth of 1 m. Groundwater is at a great depth from the ground surface.

Substructure (Foundation)

The activities usually carried out under substructure works are setting out, excavation, concrete works (blinding, column bases, strip foundation, column stubs, and ground floor slab), reinforcement works, carpentry works, and filling.

Setting out

3 bundles of pegs @ ₦2500 = ₦7500

20 pcs of 2″ x 3″ softwood @ ₦750 = ₦15000

1 bag of 3″ and 2″ nails each @ ₦48,000 each = ₦96,000

6 rolls of twin ropes @ ₦500 = ₦3000

Labour and supervision (allow) = ₦100,000

Total for setting out = ₦221,500

Excavation works

Excavation of 82 m3 of earthwork for the column bases and the strip foundation @ ₦1,800/m3 = ₦147,600

Supervision = ₦60,500

Total cost for excavation works = ₦208,100

Concrete Works (foundation)

Blinding and casting of column base and strip foundation = 26.5 m3 of grade 25 concrete @ ₦108,600/m3 = ₦2,877,900

Labour and supervision cost = ₦425,000

Total cost for concrete works = ₦3,302,900

Reinforcement Works

Column base mat reinforcements = 384 kg of Y12 @ ₦1005/kg = ₦385,920

Column starter bars reinforcements = 455 kg of Y16 @ ₦1005/kg = ₦457,275

Column base links = 50 kg of Y8 @ ₦1005/kg = ₦50,250

Binding wire 1 roll @ ₦34,000 = ₦34,000

Labour and supervision cost = ₦100,000

Total cost for reinforcement works = ₦1,027,445

Block work

170 m2 of 9″ hollow block work @ ₦10,150/m2 = ₦1,725,500

Labour and supervision = ₦254,000

Total for block work = ₦1,979,500

Carpentry Works

Column stubs – 13.5 m2 of 1″ x 10″ plank @ ₦3525/m2 = ₦47,590

Slab edge formwork- 50 m length of 1″ x 9″ plank @ ₦780/m = ₦39,000

20 pcs of 2″ x 3″ bracings @ ₦750 = ₦15,000

Labour and supervision costs = ₦40,000

Total cost for carpentry works = ₦141,590

Backfilling and Compaction

150 tonnes of lateritic earth fill @ ₦6000/tonne = ₦900,000

Labour cost (allow) = ₦150,000

Total cost for backfilling and compaction = ₦1,050,000

BRC Mesh

160 m2 of A142 BRC mesh @ ₦1400/m2 = ₦224,000

Cost of installation = ₦25,000

Total cost of BRC mesh works = ₦249,000

Damp Proof Membrane

Allow ₦75,000 for purchase and installation = ₦75,000

Casting of ground floor slab

Blinding and casting of column base and strip foundation = 22.5 m3 of concrete @ ₦108,600/m3 = ₦2,443,500

Labour and supervision = ₦365,000

Total cost for concreting ground floor slab = ₦2,808,500

Total cost of substructure (foundation to DPC) = ₦11,063,535

Ground Floor to Overhead Level

Block work

212 m2 of 9″ hollow block work @ ₦10,150/m2 = ₦2,151,800

Labour and supervision = ₦304,400

Total cost for block work = ₦2,456,200

Concrete Works (Lintel and Columns)

9m3 of concrete @ ₦108,600/m3 = ₦977,400

Labour and supervision = ₦146,000

Total cost for concrete works = ₦1,123,400

Reinforcement Works

Y16 for columns – 512 kg @ ₦1005/kg = ₦514,560

Y12 for lintels – 405 kg @ ₦1005/kg = ₦407,025

Y8 for lintel and column links – 232 kg @ ₦1005/kg = ₦233,160

1 roll of binding wire = ₦34,000

Labour and supervision cost = ₦120,000

Total cost for reinforcement works = ₦1,308,745

Carpentry Works

Column formwork = 31.5 m2 of 1″ x 10″ plank @ ₦3525/m2 = ₦111,040

Lintel formwork (sides) = 46.5 m2 of 1″ x 10″ plank @ ₦3525/m2 = ₦163,915

Lintel formwork (bottom) = 12m2 of sawn 1″ x 9″ plank @ ₦3525/m2 = ₦42,300

Labour and supervision cost = ₦120,000

Total cost of carpentry works = ₦437,255

Total cost from ground floor to overhead level = ₦5,325,600

First Floor Decking

Formwork

1” x 9” x 12’ plank as soffit to slab and staircase = 155 m2 @ ₦3525/m2 = ₦546,375

1” x 9” x 12’ plank as sides to beam = 46.5 m2 of 1″ x 10″ plank @ ₦3525/m2 = ₦163,915

1” x 6” x 12’ plank as sides to beam and riser to staircase = 45 pcs @ ₦1200/pcs = ₦54,000

2” x 3” x 12 softwood = 120 pcs @ ₦750/pcs = ₦90,000

Bamboo props = 275 pcs @ ₦600/pcs = ₦165,000

2 bags of 2″ and 3″ nails each = ₦192,000

Labour and supervision cost = ₦300,000

Total cost of carpentry works = ₦1,511,290

Reinforcement Works

Y16 for beams – 855 kg @ ₦1005/kg = ₦859,275

Y12 for slab – 2425 kg @ ₦1005/kg = ₦2,437,125

Y10 for slab – 295 kg @ ₦1005/kg = ₦296,475

Y8 for links of beams – 190 kg @ ₦1005/kg = ₦190,950

2 rolls of binding wire @ ₦34,000 = ₦68,000

Labour and supervision cost = ₦300,000

Total cost of reinforcement works = ₦4,151,825

Electrical and Mechanical Piping Works

Allow – ₦800,000

Concreting of the slab, beams, and staircase

33m3 of concrete @ ₦108,600/m3 = ₦3,583,800

Labour and supervision cost = ₦512,000

Total cost of concreting = ₦4,095,800

Total cost of first floor decking = ₦10,558,915

First Floor to Roof Overhead Level

Block work

223 m2 of 9″ hollow block work @ ₦10,150/m2 = ₦2,263,500

Labour and supervision = ₦429,100

Total cost for block work = ₦2,692,600

Concrete Works (Lintel and Columns)

9m3 of concrete @ ₦108,600/m3 = ₦977,400

Labour and supervision = ₦157,500

Total cost for concrete works = ₦1,134,900

Reinforcement Works

Y16 for columns – 512 kg @ ₦1005/kg = ₦514,560

Y12 for lintels – 405 kg @ ₦1005/kg = ₦407,025

Y8 for lintel and column links – 232 kg @ ₦1005/kg = ₦233,160

1 roll of binding wire = ₦34,000

Labour and supervision cost = ₦150,000

Total cost for reinforcement works = ₦1,338,745

Carpentry Works

Column formwork = 31.5 m2 of 1″ x 10″ plank @ ₦3525/m2 = ₦111,040

Lintel formwork (sides) = 46.5 m2 of 1″ x 10″ plank @ ₦3525/m2 = ₦169,915

Lintel formwork (bottom) = 12m2 of sawn 1″ x 9″ plank @ ₦3525/m2 = ₦42,300

Labour and supervision cost = ₦150,000

Total cost of carpentry works = ₦473,255

Total Cost from the first floor to roofing level = ₦5,639,500

Cost Summary

Total cost of substructure (foundation to DPC) = ₦11,063,535

Total cost from ground floor to overhead level = ₦5,325,600

Total cost of first floor decking = ₦10,558,915

Total Cost from the first floor to the roofing level = ₦5,639,500

Total cost = ₦32,587,550

Allow 25% for contractor’s profit and overhead = ₦8,146,890

Therefore, the total cost of constructing a 4-bedroom duplex from the foundation to the roofing level should range between ₦32,587,550 to ₦40,734,437. Note that different professionals and contractors may have their own scale of fees or rates for executing every item of work which may vary from what is presented here.

For your building design and construction services, contact;

Structville Integrated Services Limited

Phone/WhatsApp: +2348060307054, +2347053638996

E-mail: info@structville.com

Very nice article with photos and clear numbers. This really helps the client visualize their approximate costs all in one. Do you have it in Excel spreadsheet format for users to download and change the numbers to suit their own project?

I do have a question. I see these estimates are from March 2022 which is fairly recent. How up to date are the prices and costs today in July 2022? I know there has been inflation but I don’t expect it to exorbitantly raise the total price. Can you reproduce this duplex right now in another state in Nigeria at the same price stated?

Please let me know. Thanks.

this is so clear..God bless you

Very well explained. Thanks

Great work but this is actually not a duplex

what is the current cost to build a 4-5 bedroom fully detached duplex in 2025