Have you ever pondered the detrimental effect of water seepage on road pavements? It is common knowledge among engineers that frequent water seepage can result in road defects such as swelling of the subgrade layer and the formation of potholes and stains on roads. Perhaps you find yourself on a road construction project with water seeping out of the ground. What solution would you proffer?

This article will discuss the use of filter media in road construction as an alternative solution to water susceptibility of road pavements from groundwater absorbed into the pavement structure by capillary action. Thus, by controlling water seepage into pavement structures, we can reduce the formation of road defects and increase the lifespan of road pavements.

Detrimental effects of water seepage

Water is vital to human existence. However, given enough time, water can destroy even the best infrastructures. Therefore, water seepage and other water-related problems pose significant threats to road pavements. For instance, water action from groundwater or high hydrostatic pressure from surrounding water features leading to frequent water seepage can erode and damage road pavements. For example, look at the adverse effect of water seepage on a road near Guam Reef Hotel in Tumon, Guam, USA.

Water seepage is a prevalent issue that occurs after heavy rainfall. For instance, additional water is in the underlying road pavement layers when groundwater rises. This extra water then creates hydrostatic pressure against the road pavement resulting in soaked road layers, which reduces the bonding strength and load-bearing capacity of the premixed road materials.

Furthermore, the prolonged seepage of water into a road pavement in conjunction with traffic loads results in several pavement defects and problems, such as the formation of road stains and potholes, settlement, rutting, cracking, stripping, ravelling, and swelling of the subgrade layer. Therefore, it becomes necessary to give maximum consideration to water-related problems and how to reduce their damaging effects during the design and construction of road pavements.

Filter media in road construction

A filter media is generally used in earthworks and other civil engineering structures, such as roads, dams, retaining walls, and embankments. For example, a subsurface filter media is essential in road projects because they help to prevent the decrease in the strength of the underlying layers of road pavement caused by increased water or moisture content.

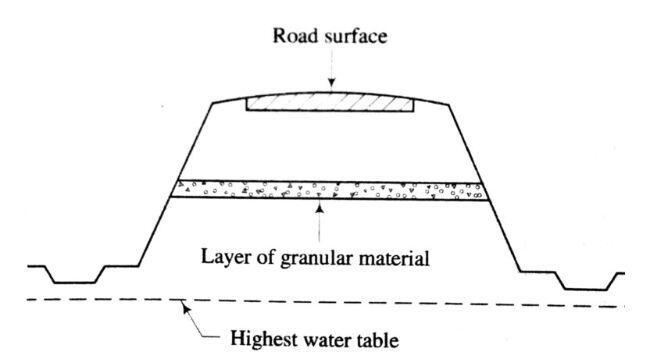

Similarly, a layer of filter media is necessary when the surface of a road has its highest water table sufficiently below the crust of the road, and there is a likelihood of water rising to the subgrade or road surface through capillary action.

When filtering is targeted at preventing water seepage into a road pavement, a filter media is a layer of free-draining granular materials or clasts (e.g. cobblestones) underneath a road’s sub-base layer. The layer of granular materials or cobblestones of suitable thickness is usually provided to cut off capillary action between a road’s subgrade and its highest water table. Thus, granular materials or cobblestones prevent the build-up of hydrostatic or water pressure on the road pavement layer.

Filtering in road construction significantly reduces road defects and failures resulting from water seepage. When filter materials are provided, the water that is supposed to rise into the underlying road layers will drain away into roadside drains. Furthermore, filtering with cobblestones is a suitable solution to controlling the capillary rise in waterlogged terrains where the subgrade is usually subjected to extreme soaking conditions due to high ground water table levels.

Selection criteria for granular materials and cobblestones as filter media

The filter media for roadbed drainage to remove seepage water and prevent damage to road pavements from uplift pressure may consist of either a single layer or several layers, each with different grading. The essential criteria are the grading and permeability of the granular materials and cobblestones. However, any filter material used as a filter media must be clean, hard, durable, dimensionally stable, and corrosion, dissolution, and frost-resistant.

Furthermore, the filter material must be free from deleterious materials that can adversely affect the efficiency and longevity of the material. These deleterious materials include clayey, elongated, flaky particles, chemically unsound or readily soluble materials, and excessively porous or laminated materials. Thus, the choice of filter material requires accessing a wide range of chemical and physical properties and sometimes depends on the judgment and experience of a designer.

The minimum acceptance criteria for granular materials and cobblestones as filter media are listed below.

- Oven-dried relative density not less than 2.5

- Maximum flakiness and elongation indices not greater than 30

- Water absorption not greater than 3% by weight

- Aggregate impact value, not more than 30

- Aggregate crushing value, not more than 30

- 10% fines value not less than 100 kN

- Los Angeles abrasion value not greater than 40

- Aggregate abrasion value not greater than 20

- Magnesium sulfate soundness value not more than 12% loss

Road construction procedures with cobblestones as filter media

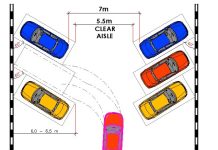

The construction procedures follow the standard methods for constructing asphalt concrete roads, except for introducing cobblestones as a filter layer. The procedures are briefly discussed below;

- Planning

- Marking out of road alignment and dimensions

- Earthworks, including excavation, grading and compaction of road subgrade

- Placement of precast or casting of in-situ roadside flood drains

- Laying of a suitable filter layer (cobblestones) with appropriate thickness where required along the stretch of the road

- Laying, grading and compaction of sub-base and base courses

- Laying and compaction of binder and surface or wearing asphalt courses

- Lastly, it is essential to note that quality control is compulsory at every construction stage.

Alternative materials for filter media

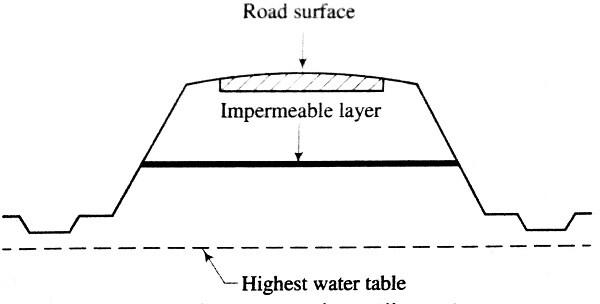

Bituminous material

An impermeable or bituminous layer covering a road section to seal water underneath the road’s sub-base can also serve as a filter media. Bitumen, made up of organic liquids that are highly viscous, sticky, and waterproof, is insoluble in water and water-resistant, thus, making it a viable alternative as an effective sealant and filter media. In addition, a filter media of bituminous material has significant advantages of availability and affordability and can be used over long stretches of a roadway.

Geosynthetics

These materials can be used as filters in addition to or in place of traditional granular materials in road construction. Furthermore, geosynthetics are easy to install, have low permeability, and are often cost-effective, especially when granular materials are scarce and expensive or when the available ones do not meet project specifications.

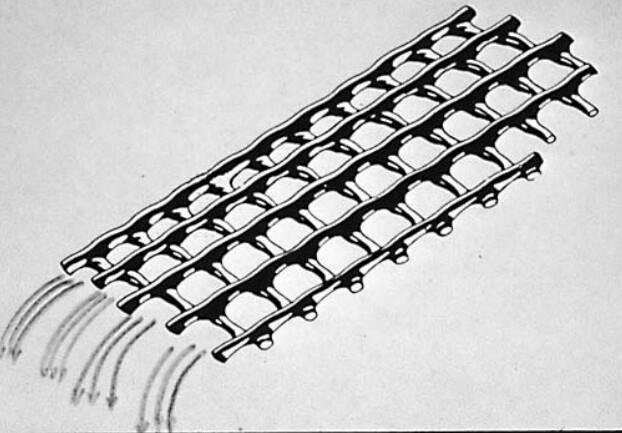

Common geosynthetics used as filter media are geomembranes, geotextiles, and geonets. Also, it can be a combination of geotextiles and geonets to form a drainage geocomposite, whereby the geotextile act as a filter while the geonet serves as a drain. For example, geonets are designed in such a way that they can convey maximum anticipated seepage within their channels during their design life. Similarly, geotextiles are designed to dissipate pore water pressure at the base of roadway structures.

Conclusion

Capillary water that seeps into a road pavement attacks the bond between the asphalt binder and aggregates in the pavement. It is important however to note that keeping road pavements from coming in contact with water can be almost impossible. However, if you ignore and refuse to treat water seepage right away as a design or construction engineer, you put the road or a stretch of the road at risk of defects andfailure.

Therefore, a road or highway engineer needs to be aware of the potential sources of water on a road project and make provisions for them. For instance, providing a filter layer becomes necessary to prevent long-term damage or collapse if the water source is groundwater seepage. Lastly, it is vital to design and construct roads such that their water susceptibility is minimized and their service life is improved.

References

[1] Gourc, J. P. (2006), “Training Course on Geosynthetics: Geosynthetics in Drainage and Filtration”, International Geosynthetics Society (8IGG), Yokohama, Japan, September, available at: https://www.geosyntheticssociety.org/wp-content/uploads/2014/10/TrainingCourse_GeosyntheticsinDrainageandFiltration.pdf

[2] Engineering Geology Special Publications (2007), Aggregates for use in filter media, Geological Society, London, Vol. 17, No. 1, pp. 291-298, available at: https://doi.org/10.1144/GSL.ENG.2001.017.01.13 or https://www.scribd.com/document/400882158/Aggregates-for-Use-in-Filter-Media