Earth materials are extensively utilised for highway construction in Nigeria. It has been recognised that high quality lateritic soils which are abundant in Nigeria can be used as fill, sub-base, and base course materials in highway construction. In this article, we are going to show the recommended standards for highway materials based on Federal Ministry of Works Specifications for Roads and Bridges (1997).

Generally, the material to be used for highway construction shall not be excavated from swamps, marshes or bogs. Furthermore, they shall be free from peat, logs, stumps, roots, and other perishable or combustible materials. Top soils and highly organic clays and silt shall not to be used for constructiont. All clays having liquid limit exceeding 80% or plasticity index exceeding 55 should be rejected.

The basic recommendations given for base course materials are for crushed stone base in clauses 6250, 6251, and 6252. Therefore, the recommendations for sub-base course materials shall be deemed to apply to base course earth materials too. Recommendations for crushed stone base will not be covered in this this article.

List of Tests for selection of highway earth materials

The lists of test that shall be conducted for highway materials are;

(1) Plasticity tests

(2) Grading tests

(3) Compaction tests

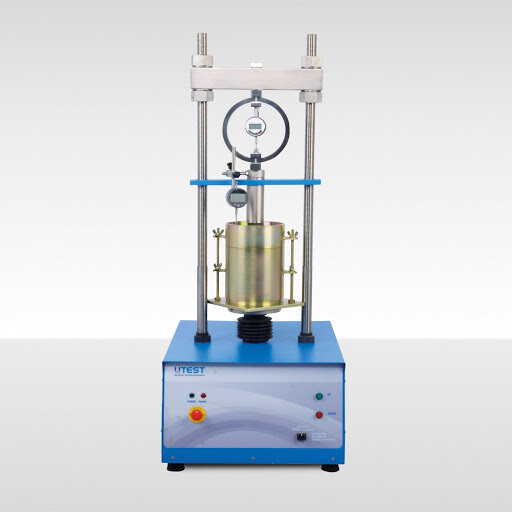

(4) Laboratory CBR tests

Materials for sub-base course (Type 1) – Heavy Traffic

(1) The percent by weight passing No 75μm sieve shall not be greater than 35%

(2) The material passing 425μm sieve shall have a liquid limit not more than 35% and plasticity index of nit more than 12%

(3) The material shall have unsoaked CBR value of 80% using Modified AASHTO or West African Standard Compaction and minimum CBR of 30% after 24 hours soaking.

Materials for sub-base course (Type 2) – Light Traffic

(1) The percent by weight passing No 75μm sieve shall not be greater than 35%

(2) The material passing 425μm sieve shall have a liquid limit not more than 35% and plasticity index of nit more than 12%

(3) The material shall have unsoaked CBR value of 80% using Modified AASHTO or West African Standard Compaction and minimum CBR of 20% after 24 hours soaking.

Materials for sub-base course (Type 3) – Substandard materials

When the site engineer recognises that suitable materials are not available for use, and the materials slightly fall short of the required standard, the following measures can be adopted;

(1) Compacting the material to a lesser density at the wet side of the optimum to contain the tendency of the material to shrink or swell.

(2) Mechanical stabilisation of the material with sand (if available) to reduce the fines content

This is the second of your material that I am reading. You are good