Timber joists are flexural horizontal timber members that are used for framing an open space in a building in order to support a floor or sheathing. They are usually closely spaced (usually between 400 – 800 mm) with the plane of maximum strength positioned vertically.

The spans of the joists are usually supported or intercepted by blockings which may be linear or skewed (staggered). Timber joists transfer the load of the floor to the vertical compression members (such as timber columns) and can be made of solid timber, glulam, or other engineered wood products.

As flexural structural members, the design of timber joists is expected to satisfy the following requirements;

- Bending

- Shear

- Bearing

- Lateral buckling

- Deflection, and

- Vibration

Design Example of Timber Joists

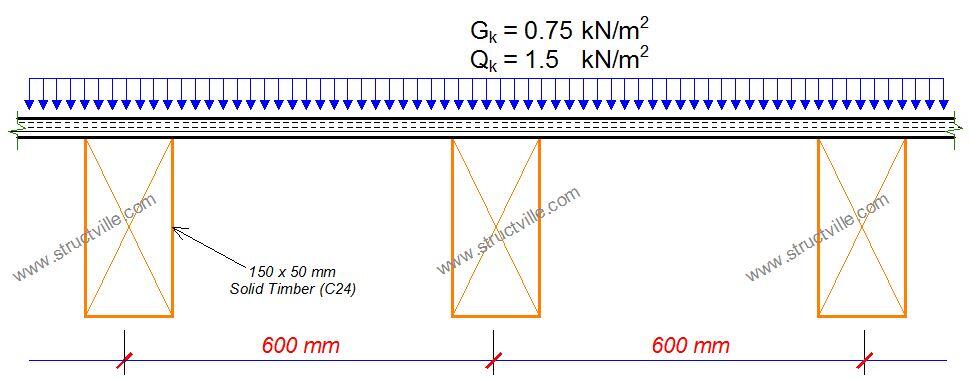

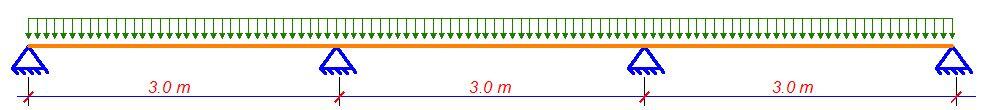

In this article, let us design the timber floor joists for a domestic dwelling using timber of strength class C24 to support a medium-term permanent action of 0.75 kN/m2 and a variable (live) load of 1.5 kN/m2 given that the:

a) floor width, b, is 3.6 m and floor span, l, is 3.0 m

b) joists are spaced at 600 mm centres

c) the bearing length is 100 mm

Self weight of timber = 3.4335 kN/m3 x 0.15m x 0.05m = 0.0257 kN/m

Chaaracteristic permaent action on each joist = 0.75 kN/m2 x 0.6m = 0.45 kN/m

Total characteristic permanent action gk = 0.476 kN/m

Total characteristic variable action qk = 1.5 kN/m2 x 0.6 m = 0.9 kN/m

At ultimate state; pEd = 1.35gk + 1.5qk = 1.9926 kN/m

At serviceability limit state pEd = 1.0gk + 1.0qk = 1.376 kN/m

Structural Analysis

Structural Design

Member – Span 1

The partial factor for material properties and resistances

Partial factor for material properties (Table 2.3 of EN 1995-1-1:2004); γM = 1.300

Member details

Load duration (cl.2.3.1.2 of EC5); Medium-term

Service class – (cl.2.3.1.3 of EC5); 2

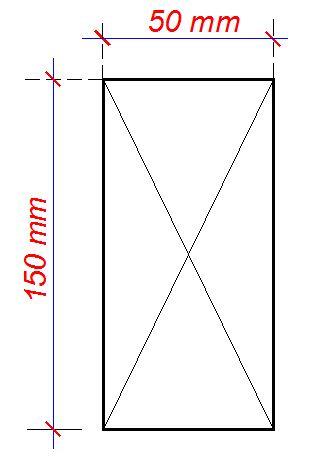

Timber section details

Number of timber sections in member; N = 1

Breadth of sections; b = 50 mm

Depth of sections; h = 150 mm

Timber strength class – EN 338:2016 Table 1; C24

Properties of 50 x 150 mm timber section

Cross-sectional area, A = 7500 mm2

Section modulus, Wy = 187500 mm3

Section modulus, Wz = 62500 mm3

Second moment of area, Iy = 14062500 mm4

Second moment of area, Iz = 1562500 mm4

Radius of gyration, iy = 43.3 mm

Radius of gyration, iz = 14.4 mm

Timber strength class C24

Characteristic bending strength, fm.k = 24 N/mm2

Characteristic shear strength, fv.k = 4 N/mm2

Characteristic compression strength parallel to grain, fc.0.k = 21 N/mm2

Characteristic compression strength perpendicular to grain, fc.90.k = 2.5 N/mm2

Characteristic tension strength parallel to grain, ft.0.k = 14.5 N/mm2

Mean modulus of elasticity, E0.mean = 11000 N/mm2

Fifth percentile modulus of elasticity, E0.05 = 7400 N/mm2

Shear modulus of elasticity, Gmean = 690 N/mm2

Characteristic density, rk = 350 kg/m3

Mean density, rmean = 420 kg/m3

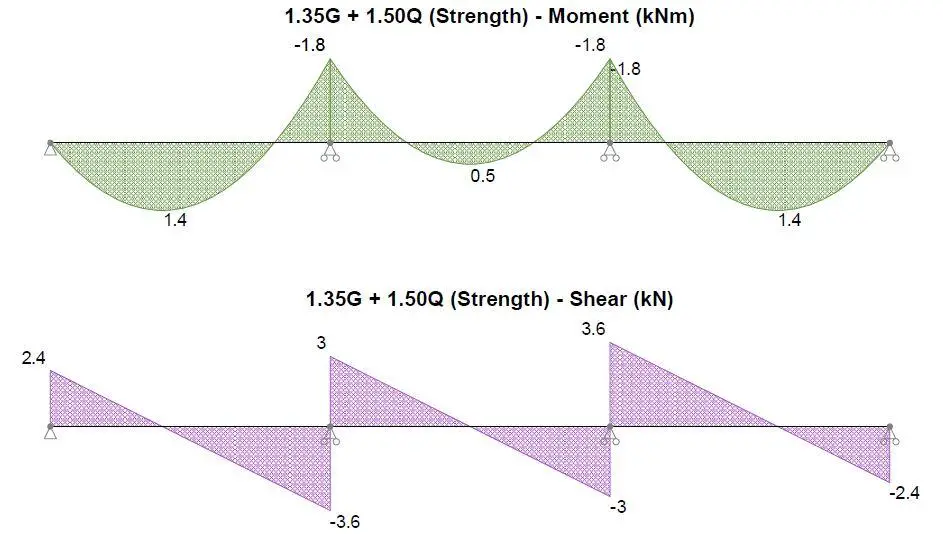

Consider Combination 1 – 1.35Gk + 1.5Qk (Strength)

Modification factors

Duration of load and moisture content – Table 3.1; kmod = 0.8

Deformation factor – Table 3.2; kdef = 0.8

Bending stress re-distribution factor – cl.6.1.6(2); km = 0.7

Crack factor for shear resistance – cl.6.1.7(2); kcr = 0.67

Load configuration factor – cl.6.1.5(4); kc,90 = 1.5

System strength factor – cl.6.6; ksys = 1.1

At the start of span

Check compression perpendicular to the grain (cl.6.1.5 of EC5)

Design perpendicular compression – major axis; Fc,y,90,d = 2.394 kN

Effective contact length; Lb,ef = Lb = 100 mm

Design perpendicular compressive stress – exp.6.4; sc,y,90,d = Fc,y,90,d / (b × Lb,ef) = 0.479 N/mm2

Design perpendicular compressive strength; fc,y,90,d = kmod × ksys × fc.90.k / γM = 1.692 N/mm2

sc,y,90,d / (kc,90 × fc,y,90,d) = 0.189

PASS – Design perpendicular compression strength exceeds design perpendicular compression stress

Check shear force (Section 6.1.7 of EC5)

Design shear force; Fy,d = 2.394 kN

Design shear stress – exp.6.60; ty,d = 1.5 × Fy,d / (kcr × b × h) = 0.714 N/mm2

Design shear strength; fv,y,d = kmod × ksys × fv.k / γM = 2.708 N/mm2

ty,d / fv,y,d = 0.264

PASS – Design shear strength exceeds design shear stress

At the end of span

Check compression perpendicular to the grain – cl.6.1.5

Design perpendicular compression – major axis; Fc,y,90,d = 6.572 kN

Effective contact length; Lb,ef = Lb = 100 mm

Design perpendicular compressive stress – exp.6.4;

sc,y,90,d = Fc,y,90,d / (b × Lb,ef) = 1.314 N/mm2

Design perpendicular compressive strength;

fc,y,90,d = kmod × ksys × fc.90.k / γM = 1.692 N/mm2

sc,y,90,d / (kc,90 fc,y,90,d) = 0.518

PASS – Design perpendicular compression strength exceeds design perpendicular compression stress

Check shear force – Section 6.1.7

Design shear force; Fy,d = 3.583 kN

Design shear stress – exp.6.60; ty,d = 1.5 × Fy,d / (kcr × b × h) = 1.070 N/mm2

Design shear strength; fv,y,d = kmod × ksys × fv.k / γM = 2.708 N/mm2

ty,d / fv,y,d = 0.395

PASS – Design shear strength exceeds design shear stress

Check bending moment – Section 6.1.6

Design bending moment; My,d = 1.784 kNm

Design bending stress; sm,y,d = My,d / Wy = 9.517 N/mm2

Design bending strength; fm,y,d = kmod × ksys × fm.k / γM = 16.246 N/mm2

sm,y,d / fm,y,d = 0.586

PASS – Design bending strength exceeds design bending stress

Serviceability Limit State

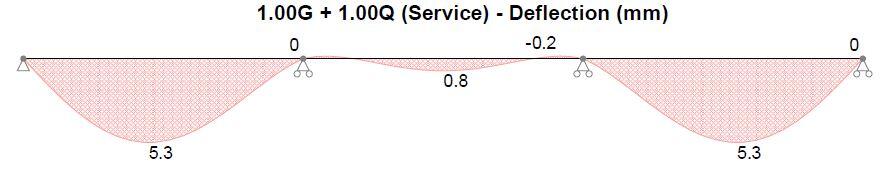

Consider Combination 2 – 1.0Gk + 1.0Qk (Service)

Check y-y axis deflection – Section 7.2

Instantaneous deflection; dy = 5.3 mm

Quasi-permanent variable load factor; y2 = 0.3

Final deflection with creep; dy,Final = 0.5 × dy × (1 + kdef) + 0.5 × dy × (1 + y2 × kdef) = 8.1 mm

Allowable deflection; dy,Allowable = L / 250 = 12 mm

dy,Final / dy,Allowable = 0.676

Therefore, the final deflection is acceptable.

It is also typical to check the floor for vibration, but this was not considered in this design.

Hello. I was going through this and its great work. But i am not understanding how you are able to get the design perpendicular compression at the start of the span and at the end as 2.394 and 6.572.where did you calculate them from

Hi Brian, take a look at the shear force diagram, the support reaction at the start of the span is 2.394 kN (approximated as 2.4 kN, while the total support reaction at the penultimate support is approximately 6.6 kN (3 + 3.6 = 6.6 kN).