Bamboo is a perennial, evergreen, hollow-stemmed plant that is woody, hard, and green in appearance. It is a member of the Poaceae family of true grass. In fact, with 91 genera and more than 1000 species, it is the largest member of the grass family. While some of its members are big, others are more normal. Around the world, bamboo can be found in a variety of climates, from chilly mountains to tropical areas. Bamboo and its derivatives have been used in construction, textile production, medicine, and as food.

It is important to note that not all species of bamboo can be used for construction purposes. Only a few species of bamboo, such as Guadua angustifolia (Guadua Bamboo) and Phyllostachys edulis (Moso Bamboo), have compression ratios that are nearly twice as high as those of concrete and steel, respectively.

According to Bornoma et al (2016), the bamboo-built homes remained standing and unaffected by the tremendous earthquake that rocked Colombia in 1999, but practically all concrete buildings were seriously affected. This article examines the numerous mechanical properties of bamboo and how they might be applied to architectural design and examples of potential domestic building construction.

Bamboo Anatomy and Structure

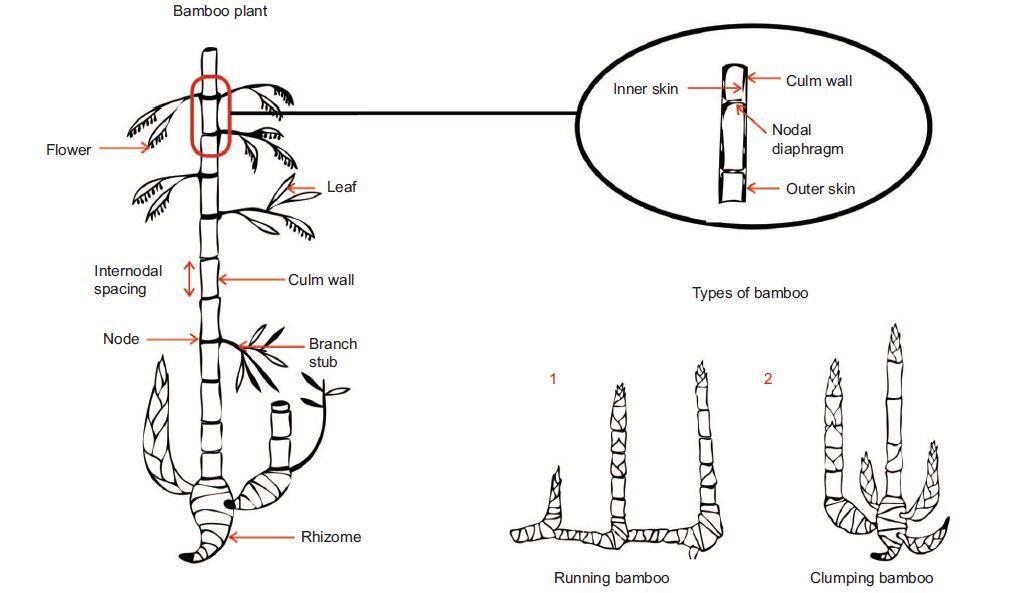

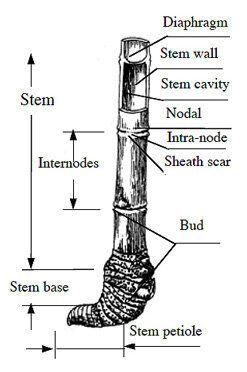

The structure of bamboo, which determines its ultimate mechanical qualities, is described in the anatomy of bamboo. The three fundamental parts of the bamboo culm are depicted below:

- The above-ground stem, which may be straight or bent.

- The stem base, which is the lower portion of the stem that reaches the ground.

- The stem petiole, which is composed of several short sections and is the lowest part of the stem.

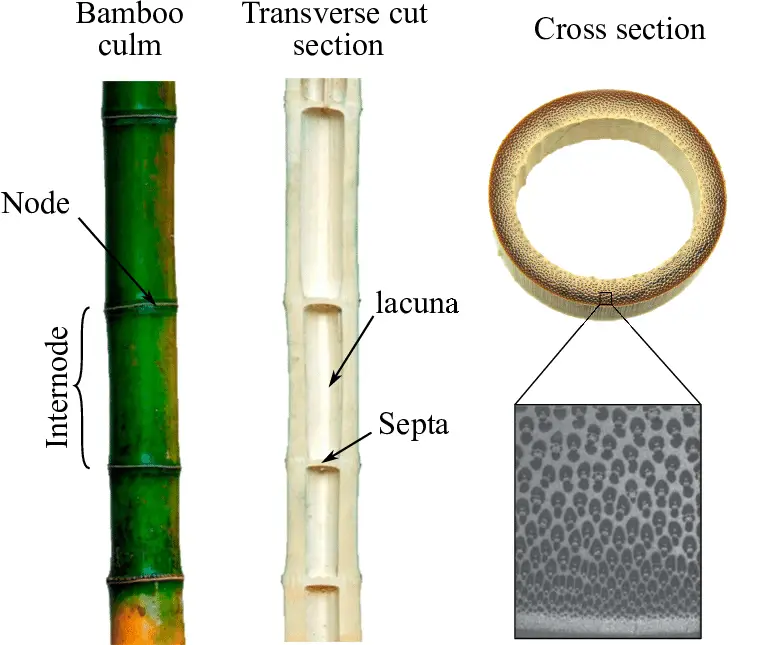

The internodes and nodes, also known as diaphragms, make up the culm’s structural components. Cells that are traverse-oriented or parallel to the nodes make up the nodes, whereas cells that are axially orientated make up the internodes. Since culms are typically hollow like tubes, the distance between the inner and outer surfaces of the stem is determined by the thickness of the wall. However, some species have solid culms.

Mechanical Properties of Bamboo

Along its fibre direction, bamboo has stronger mechanical qualities than across it. Natural bamboo is a viable renewable material for construction in high performance applications due to its distinct microstructural characteristics in relation to its mechanical capabilities.

Because of its readily available nature and established mechanical properties, bamboo can be utilised as an alternative to steel for masonry reinforcing. The yield tensile strength of bamboo has outperformed several materials in some tests, including steel. However, being a natural material, bamboo’s distinctive high performance differs from one kind to another; as a result, anytime mechanical property values of bamboo are mentioned, the name of the relevant bamboo type is required.

The hollow, tubular structure of bamboo, which it evolved over millennia to withstand wind forces in its native habitat, gives it its tensile strength. It is also simple to harvest and transport thanks to the structure’s low weight. Bamboo is also very affordable because of its incredibly quick growth cycle and the range of environments in which it may grow. Because grass grows so quickly and has to absorb so much CO2, cultivating it as a building material would slow down the rate of climate change. The development of bamboo as reinforcement is encouraged by only these characteristics.

In spite of these advantages, there is still effort to be done to get over bamboo’s drawbacks. One such limitation, brought on by both temperature variations and water absorption, is contraction and expansion. Fungus and naturally occurring biodegradation-induced structural weakening in bamboo is another risk factor. Ironically, numerous nations that might gain from bamboo reinforcement also lack the resources necessary to develop it as a practical replacement for the steel they currently rely on.

Moisture Content

Raw bamboo’s moisture content (MC) is an important factor, particularly for uses in the building and construction industry and for the creation of composite materials. The bonding strength of bamboo fibres in composite goods and bamboo laminates may be negatively impacted by MC. The performance and service life of new bamboo composite materials are therefore anticipated to be significantly impacted by the moisture content.

The geometrical features of raw bamboo, such as dimensional stability, are also impacted by moisture content in addition to its effects on mechanical parameters, such as tensile strength and flexural strength. Despite the fact that many research works have looked at the impact of water absorption on the dimensional stability of raw bamboo and bamboo composite specimens, they haven’t looked at the relationship between green bamboo’s water absorption and its mechanical characteristics. Rapid fluctuations in moisture can cause bamboo layers to shrink or expand significantly, which could fracture layer bonds, particularly when bamboo is used in laminates or composites.

Therefore, before processing the raw bamboo fibres into composites or laminates, it is crucial to determine the moisture content of different sections of raw bamboo and classify the moisture content according to the location within the culm length.

Density of Bamboo

The density of bamboo typically increases on the outside surface and decreases toward the inner layers of the wall cross section, according to a number of studies. As a result, bamboo culms’ outer layers are thought to possess superior mechanical properties. However, no exhaustive and systematic investigations of the density and culm geometry of bamboo, including wall thickness, culm diameter, and culm height, have been discovered to date. The performance of bamboo may be significantly affected by the determination of sections with higher fibre densities and conceivably improved quality in terms of physical and mechanical qualities.

The properties of some bamboo species are shown below;

| BAMBOO SPECIE | SL (m) | DBH (cm) | IL (cm) | NI (unit) | DW (kg) | BD (g/cm3) |

| Bambusa beecheyana | 8.97 | 7.80 | 28 | 32 | 10.50 | 0.670 |

| B. dissimulator | 9.52 | 4.58 | 41 | 23 | 5.19 | 0.780 |

| B. malingensis | 7.36 | 4.33 | 28 | 26 | 3.49 | 0.700 |

| B. nutans | 9.95 | 5.83 | 38 | 26 | 7.75 | 0.615 |

| B. oldhamii | 9.93 | 6.94 | 41 | 24 | 8.37 | 0.608 |

| B. stenostachya | 15.10 | 8.17 | 35 | 43 | 17.50 | 0.653 |

| B. textilis | 8.13 | 4.77 | 44 | 18 | 3.80 | 0.690 |

| B. tulda | 11.90 | 6.56 | 49 | 24 | 11.89 | 0.773 |

| B. tuldoides | 9.15 | 4.26 | 46 | 19 | 3.75 | 0.620 |

| B. ventricosa | 9.30 | 4.84 | 44 | 21 | 4.47 | 0.640 |

| B. vulgaris | 10.70 | 8.06 | 32 | 33 | 12.45 | 0.747 |

| B. vulgaris var. vittata | 9.30 | 7.22 | 34 | 27 | 10.27 | 0.730 |

| Dendrocalamus asper* | 25.60 | 15.40 | 46 | 62 | – | – |

| D. asper | 14.50 | 12.20 | 34 | 43 | 36.93 | 0.599 |

| D. giganteus | 16.00 | 14.20 | 34 | 47 | 40.73 | 0.552 |

| D. latiflorus | 11.50 | 11.50 | 37 | 31 | 21.58 | 0.683 |

| D. strictus | 10.00 | 7.60 | 38 | 26 | 8.94 | 0.667 |

| Guadua amplexifolia | – | – | – | – | – | 0.654 |

| G. angustifolia | – | – | – | – | – | 0.451 |

| G. spinosa | – | – | – | – | – | 0.489 |

| G. superba | – | – | – | – | – | 0.559 |

| Ochlandra travancorica | 11.30 | 9.40 | 40 | – | 26.00 | 0.704 |

* Stem length without a minimum diameter.

In a study by Omaliko and Ubani (2021), the density of bamboo specimens (Guadua angustifolia) at 12% moisture content were observed to range from 712.84 to 799.70 kg/m3. It was also observed that the node region has a somewhat higher density than the internode section. This is in line with the observations made by Huang et al. (2015), who found that specimens with and without nodes varied in density. This difference is caused by a unique characteristic of node vascular bundles, which show less vascular bundle content, shorter fibre length, and wider parenchyma cell lumens than internodes.

Specific Density of Bamboo

It is important to measure both specific density (SD) and moisture content (MC) values and link them to the mechanical characteristics of raw bamboo since the specific density of raw bamboo is a potential predictor of the qualities of bamboo-based products, such as laminates and bamboo composite materials. The specific density (SD) is the weight of an equal volume of water divided by the oven-dry weight of a given volume of raw bamboo. MC values and SD values have a close relationship. To guarantee that results are comparable with those from other studies, a standardised procedure for measuring SD and MC is required.

Specific density values will vary from the outer to inner portion of the wall cross section as the fibre density varies with wall thickness. Therefore, it is necessary to know which portion of the wall cross section is processed and what the associated MC and SD of that portion are before using raw bamboo for any application. The best bamboo sections can be chosen for the creation of items made of bamboo that meet specific criteria by measuring the MC and SD values and correlating them with measurements of wall thickness and mechanical properties.

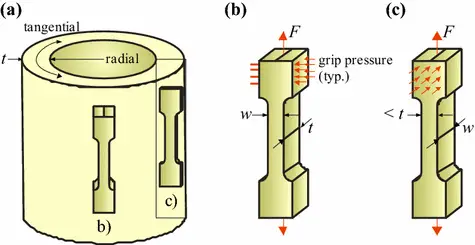

Tensile Strength

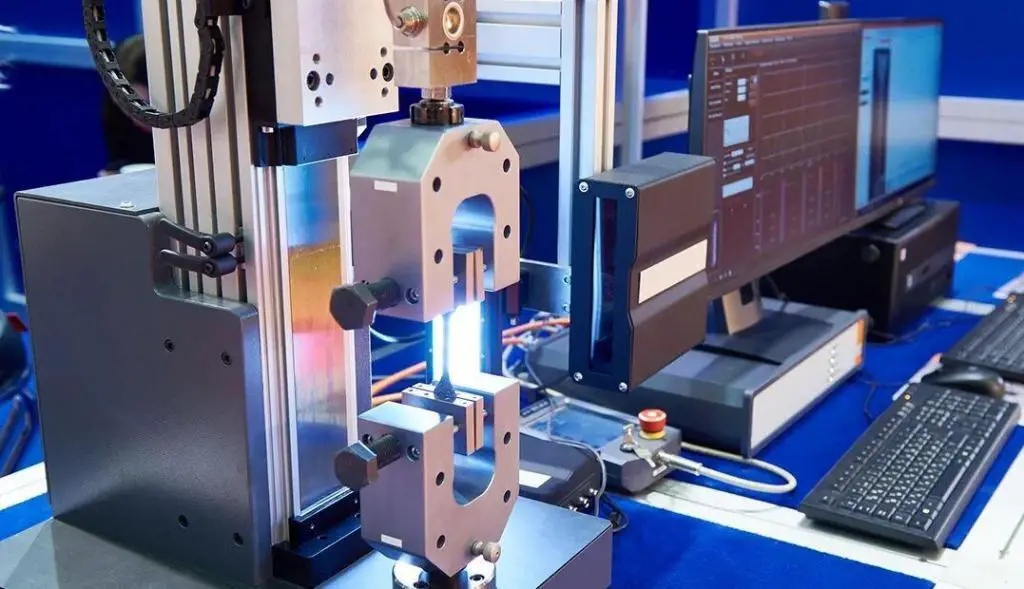

A 100 kN tensile testing machine can be used to determine the tensile strength of bamboo samples in the lab using the ASTM D143-09 standard test technique for small clear specimens of timber. Samples can be made into dog-bone shapes after being cut from the 1m sections of bamboo culms that have been selected from various radial points along the sections. The sample’s average width and length can be 25 and 50 mm, respectively, while the gauge length can be 130mm on average. The ultimate load at test failure (Fult) is measured, and its value is divided by the cross section of the sample across the gauge length (A), to determine the tensile strength.

In a study on Dendrocalamus asper. samples along the fibre direction by Javadian et al (2019), the highest tensile strength of class 1 samples (culm diameters of 80 to 90 mm) is 295 MPa for a wall thickness of 7-8 mm. Wall thickness categories of 6-7 mm and 8-9 mm have comparable tensile strengths within the same class. The samples with a wall thickness of 7-8mm in class 2 (90-100mm culm diameter) have the highest tensile strength of 298 MPa. There is no discernible difference between the values for other types of wall thickness because they all have comparable tensile properties.

However, as culm diameter increases, the average tensile strength for class 4-7 (diameter > 110 mm) decreases. When comparing the data from SD and tensile strength test, a correlation between the culm diameter, specific density, and tensile strength is seen. As the culm diameter increases, there is no discernible change in SD and tensile strength for class 1-3 (diameter 110 mm). The tensile strength and SD for class 4-7 (diameter > 110 mm) decrease as the culm diameter increases.

The density of bamboo fibres affects the tensile strength for culm diameters more than 110mm. Larger culms are likely to have more lignin and less cellulose fibres. As a result, raw bamboo loses a significant amount of its tensile strength, which is primarily derived from the tensile capacity of the cellulose fibres. As previously stated, the fibre density has a major impact on SD; as a result, decreasing the fibre density has been found to result in decreased SD in prior studies. When choosing bamboo culms for composite processing, the relationship between SD, tensile strength, and fibre density is important.

Flexural Strength of Bamboo

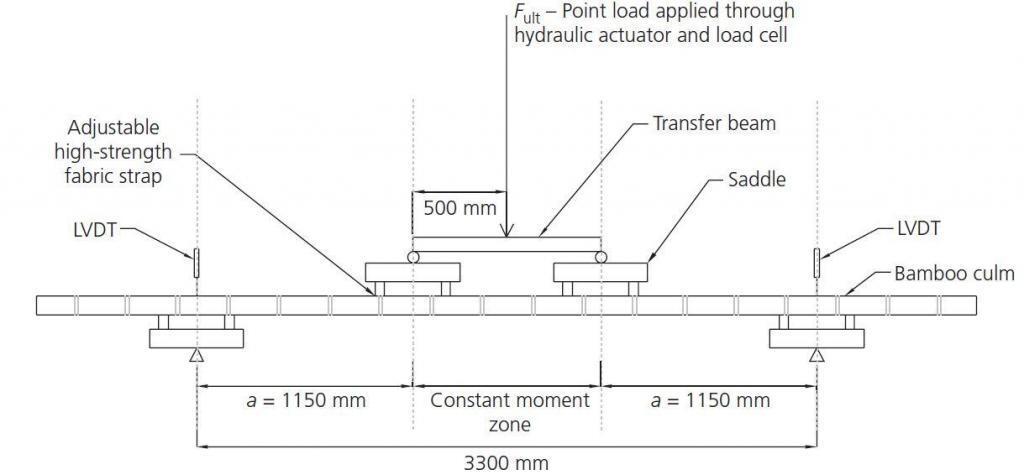

The flexural strength of bamboo can be measured according to ASTM D3043-00(2011) standard test method for structural panels in flexure. two-point flexural test is generally recommended. The advantages of a two-point flexure test over a center-point flexure test is that the sample is subjected to peak stress over a greater region as opposed to the center-point flexure test, which applies the peak stress to a single, isolated place. As a result, the likelihood that any fracture or flaw exists between two loading supports will be higher and the results of a two-point flexure test will be more accurate.

In a study by Javadian et al (2019), the flexural strength for class 1 (culm diameters of 80 to 90 mm) samples was observed to be 209 MPa, while the flexural strength for class 7 (140 – 150 mm) samples is 121 MPa. The flexural strength decreases from 209 to 198 MPa for class 1 samples when the wall thickness is increased from 6 to 9 mm.

There is no discernible correlation between the wall thickness and the flexural strength for samples from classes 2 (90-100 mm) and 3 (100 – 110 mm). In class 4 (110 – 120 mm) samples, going from a wall thickness of 6 to 10 mm causes a 6.7% decrease in the flexural strength going from 166 MPa to 155 MPa. The lowest flexural strength for class 5 (120 – 130 mm) is 149 MPa for walls with a thickness of 10 to 11 mm.

Larger culms have thicker walls, especially at the lower parts. A higher proportion of lignin and a lower proportion of cellulose fibres are caused by the thicker wall thickness. Similar conclusions can be drawn about flexural strength as they were with regard to the tensile capacity and its connection to fibre density earlier. The upper regions of the hierarchical structure of bamboo culms, where a smaller diameter predominates, are densely packed with cellulose fibres. The flexural strength of bamboo increases as culm diameter is decreased.

This emphasises how important fibre density is to the mechanical qualities of raw bamboo. Natural bamboo has exceptional mechanical properties thanks to cellulose fibres. The outer layer of the wall sections and the top portions of the culms have a higher cellulose fibre density. As a result, the flexural strength increases with rising fibre content and with falling lignin content around the fibres.

Compressive Strength of Bamboo

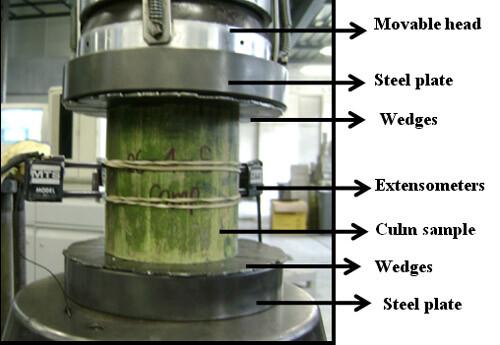

Two types of compressive strength, namely compressive strength parallel to the fibre direction and compressive strength perpendicular to the fibre direction, must be tested in accordance with the ISO 22157 standard in order to comply with European regulations. Three distinct samples of each stem will be evaluated because of the natural curvature of the bamboo stem. Three different areas of the log are sampled: the bottom, the centre, and the top. This is required because a bamboo stem does not have a continuous cross-section and because the bottom section, which has a bigger diameter, and the upper section, which has a smaller diameter, have different structural characteristics.

Chung and Yu (2002) conducted compression tests on two types of bamboo, Bambusa pervariabilis and Phyllostachya pubescens. Bambusa pervariabilis has an average ultimate compressive strength of 103 MPa and an average compressive modulus of elasticity of 10.3 GPa. Phyllostachys pubescens has an average ultimate compressive strength of 134 MPa and an average compressive modulus of elasticity of 9.4 GPa. Based on their observations, they concluded that bamboo had superior mechanical properties to regular structural lumber.

According to a study by Omaliko and Ubani (2021), the constitutive relationship of bamboo culm node sections and inter-nodal sections are different. Samples from the internodes demonstrated lower compressive strength than those from the node region of the bamboo culm. As a result, it can be concluded that nodes along the bamboo culm favourably affect the compressive strength of bamboo.

The study also demonstrated that when bamboo’s density increased, so did its compressive strength. Numerous other researchers have noted this relationship between the density and compressive strength of bamboo. They discovered that the unequal distribution of specific gravity across the bamboo culm’s heights and positions is the cause of the positive link between density and compressive strength.

Modulus of Elasticity in Tension

The rigidity of the bamboo matrix and its resistance to elastic deformation are both quantified by the bamboo’s modulus of elasticity. According to ASTM D143-14, the modulus of elasticity in tension of bamboo Petung (Dendrocalamus asper.) was tested by Javadian et al (2019) for various classes of bamboo Petung with variable culm diameters and wall thicknesses. Class 4 (110-120 culm diameter) samples with 9mm to 10mm wall thickness exhibit the highest modulus of elasticity (28,230 MPa), whilst class 7 samples (140 – 150 mm culm diameters) with 19mm to 20mm wall thickness exhibited the lowest modulus of elasticity (18,140 MPa).

The wall thickness of bamboo similarly increases as the culm diameter increases. As has been seen in earlier investigations, the volumetric ratio of cellulose fibres to lignin decreases as wall thickness increases in larger culms. As a result, thicker wall sections are anticipated to contain a higher percentage of lignin than cellulose fibres. As a result, larger bamboo culms have a lower modulus of elasticity than smaller culms, which have a higher volumetric ratio of cellulose fibres to lignin.

Shear Strength of Bamboo

The same machine that is used for a compression test can also be used to shear test bamboo culms parallel to the fibre. Additionally, the test was conducted in compliance with ISO-22157-2 (2004) procedure. The specimens can be made in the same way as a specimen for a compression test, with the exception that they were taken from the bottom, middle, and top of the bamboo culm and their length was equal to the outer diameter of the bamboo.

At each of the four shear zones, all measurements, including the specimen’s height, L, and thickness, t, should be taken. The specimens should be positioned in the middle of the moveable head, vertically. Additionally, the specimen needs to be centred in relation to the loading and supporting plate. The maximum load, Fult, shall be measured at the end of the continuous application of the load at a constant rate of 0.01 mm/s. Then, the equation below is used to determine the ultimate shear strength.

τ = Fult / ∑(t × L)

Where;

τ = Ultimate shear strength, in N/mm2

Fult = Maximum load at which the specimen fails, in N.

∑(t × L) = Sum of four product of t and L.

References

- Bornoma A. H., Faruq M. and Samuel M. (2016): Properties and Classifications of Bamboo for Construction of Buildings. Journal of Applied Sciences & Environmental Sustainability 2(4):105 – 114

- Huang, P., Chang, W., Ansell, M., Chew, Y., & Shea, A. (2015). Density distribution profile for internodes and nodes of Phyllostachysedulis (Moso bamboo) by computer tomography scanning. Construction and Building Materials, 93:197-204

- Javadian A, Smith IFC, Saeidi N and Hebel DE (2019): Mechanical Properties of Bamboo Through Measurement of Culm Physical Properties for Composite Fabrication of Structural Concrete Reinforcement. Front. Mater. 6:15. doi: 10.3389/fmats.2019.00015

- Omaliko I. K. and Ubani O. U. (2021): Evaluation of the Compressive Strength of Bamboo Culms under Node and Internode Conditions. Saudi Journal of Civil Engineering, Sept, 5(8): 251-258