Concrete is the building material that is most usually used for sewer systems because of its favorable structural qualities, capacity for prefabrication, and freedom from form restrictions. For a variety of reasons, such as the effects of (bio)chemical deterioration, ageing, and the loss of soil support, the structural integrity of concrete sewer pipes degrades with time.

The design life of a sewer system is several decades. Due to the capital-intensive nature of maintaining a sewer system as well as the severe societal and financial consequences of catastrophic failure, accurate condition evaluation has become increasingly important over time.

The two most frequent sources of data used to determine whether to repair or replace sewers are Closed-Circuit Television (CCTV) inspection and age. The difficulty of revealing deterioration on the outside of the sewer pipe wall, the low accuracy and reliability of visual inspection data, and the weak correlation between visual inspection data and material properties are just a few drawbacks that have recently been discovered with regard to these inspection methods.

Additionally, the majority of nations lack a database that contains precise information on the state of the subsurface infrastructure. Thus, it is obvious that clear knowledge about the real structural state of sewer systems is required in order to enhance current inspection techniques and enable adequate condition assessments.

The structural state of sewer networks has been the subject of numerous study investigations during the past few decades. Much emphasis has been paid to the biogenic sulphuric acid-induced degradation process that typically occurs in concrete sewer pipes.

Investigations into the sulphuric acid-producing bacteria and the chemical deterioration mechanisms that result at the inner surface of sewer pipes have revealed that the concrete’s calcium hydroxide and calcium silicate hydrate react with the acid to create gypsum and/or ettringite, which frequently causes an increase in porosity and, as a result, a decrease in strength and stiffness.

Additionally, naturally occurring carbondioxide in soil may migrate to the outside of concrete sewer pipes, where it may interact with hydrated cement in the presence of moisture. The strength, porosity, and pore size distribution of the cement paste may change as a result of this carbonation process. The assessment of the structural failure behavior of sewer pipes was the focus of additional experimental researches.

Despite the fact that the aforementioned investigations have focused on important issues and facts, a complete understanding of how (bio)chemical attack affects the mechanical performance of in-situ concrete sewer pipes is still lacking. However, this information is necessary to boost the suitable recommendations that municipalities and other stakeholders can use when making decisions about the upkeep and replacement of concrete sewer pipe systems.

Evaluation of Deterioration of old Sewer Pipes

Recently, researchers (Luimes et al, 2022) from the Department of the Built Environment, Eindhoven University of Technology, Eindhoven, The Netherlands, and Department of Hydraulic Engineering, Deltares, MH Delft, The Netherlands, studied the effects of biochemical attack on the mechanical performance of used concrete sewer pipes which they published in the journal, Construction and building materials (Elsevier).

Thirty-five used, unreinforced concrete sewer pipes provided by The Netherlands’ Municipalities of The Hague and Arnhem were used for the experimental program. The tested pipes, which range in age, size, and geometry, have been in use as combined sewer systems (i.e., the tested pipes installed in the 1920s and 1950s) or as improved separated systems (i.e., the tested pipes installed in the 1990s) up until July/August 2019 (pipes from Arnhem) and January 2020 (pipes from The Hague), respectively, without undergoing rehabilitation or protection treatments.

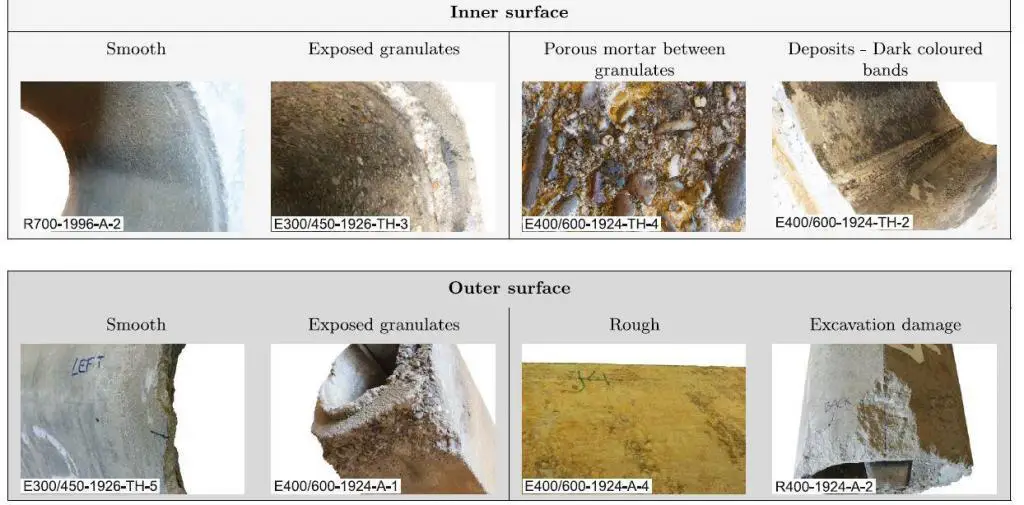

The test program involved concrete sewer pipes that had been in use for between 22 and 95 years. During that time, exposure to particular in-situ circumstances had resulted in some chemical attack, which may have been accompanied by mechanical damage from traffic loads and excavation. This might have reduced the concrete’s mechanical qualities, which might have affected the pipe’s ability to support structural loads. The inner and outer surfaces of the sewer pipes were first given a rigorous visual inspection during the study, and were then classified using various surface condition classes in order to explore these issues in more detail.

The cross-sections of the sewer pipes were also tested for residual alkalinity using a phenolphthalein method, where a pH indicator was provided by a 1 percent solution of phenolphthalein. The solution turns from pink to magenta in moderately alkaline conditions with a pH in the range of 9.2 to pH 10. The solution turns magenta in extremely alkaline surroundings with a pH > 10, but it stays colorless in somewhat alkaline and acidic conditions with a pH 9.2.

The dissolution of solid calcium-hydroxide in the pore solution causes the pH of the concrete to rise to a level above 12.5 to 13, which is shown by the magenta zones. On the other hand, the colorless zones indicate the presence of a chemical attack in the past, which may have been brought on by carbonation (8.3 < pH < 9) and biogenic suphuric acid corrosion (1< pH < 3).

X-ray diffraction (XRD) data were used by the researchers to further analyze the type of chemical attack. A total of 6 different surface condition classes were identified, and a particular place may be described by many surface conditions. The surface conditions were classified as follows in accordance with nomenclature generally used by the sewer asset management community:

- Smooth – A surface that is virtually intact and aesthetically comparable to the surface of a brand-new sewer pipe

- Exposed granulates – Exposed granulates and porous mortar between granulates referred to chemically harmed surfaces where the granulates are now visible and/or have fallen off due to the loss of the thin outer mortar layer. In the latter class, the mortar that once held the exposed granulates together has degraded into a porous, loose material that is simple to spall off.

- The deposits class — As a result of variations in the wastewater level, dark colored bands indicate obvious color changes and adhering deposits along the inner pipe surface.

- Rough – A surface with minor chemical assault symptoms, wherein a portion of the thin outer mortar layer is still covering the granulates.

- Excavation damage – This refers to relatively big scraped or broken off pieces brought about by bulldozers and excavators during the mechanical removal of the sewer pipes from the soil.

(5) Rough, and (6) Excavation damage, as observed on the inner and outer surfaces of the tested concrete sewer pipes (Luimes et al, 2022)

The types and degree of biochemical attack were respectively assessed by performing XRD analyses and phenolphthalein tests. The following conclusions were obtained from the findings.

- The process of biogenic sulphide corrosion can be blamed for a major portion of the structural deterioration of old sewer lines. This process often results in a porous mortar layer between the granulates and a weak, corroded layer that looks like exposed granulates at the inside of the pipe.

- Carbonation may have an impact on the sewer pipe’s outside, but it seems to have a very small impact on the pipe’s surface condition and is thought to be less detrimental to the structural integrity.

- In contrast to the relatively new pipes from the 1990s, the old pipes from the 1920s and 1950s typically exhibit quite significant levels of chemical attack. Despite the fact that the level of chemical attack tends to increase with pipe age, an explicit relationship between pipe age and the degree of chemical attack cannot be determined from measurement data because the pipe’s specific material composition and the surrounding environment also have a significant impact on the level of chemical degradation.

According to the researchers (Luimes et al, 2022), the study’s findings can be used to develop and improve inspection and condition assessment standards. Further research has shown that biogenic sulphide corrosion can significantly contribute to the mechanical deterioration of sewer pipes, making it prudent to keep an eye on how this corrosion process is progressing inside in-situ sewer pipes.

Source:

Luimes R. A., Scheperboer I.C., Suiker A.S.J., Bosco E., and Clemens F.H.L.R. (2022): Effect of biochemical attack on the mechanical performance of used concrete sewer pipes. Construction and Building Materials 346 (2022) 128390 https://doi.org/10.1016/j.conbuildmat.2022.128390

The contents of the cited original article published by Construction and Building Materials (Elsevier) is open access, under the CC BY license (http://creativecommons.org/licenses/by/4.0/) which allows you to share and adapt (remix) the article provided the appropriate credit is given, and the link to this license provided.