The use of swimming pools is increasingly becoming an important part of the urban lifestyle. Apart from the public swimming pools in parks and other recreation areas, a private swimming pool in a home offers a lot of benefits to the homeowner, and also increases the value of the property.

Swimming pools can be constructed of different materials such as reinforced concrete, shotcrete, plastics, composites, glass, etc. In all cases, the material to be used in the construction of a swimming pool must be able to resist the water pressure, some degree of impact, and must be watertight.

Glass swimming pools have gained popularity over the years especially due to their aesthetic appeal. The use of glass is more popular in suspended or surface swimming pools for obvious reasons. For suspended pools, glass can be used as the side panels and/or the base, while for surface pools it can be used for the side panels only. Advances in glass technology have improved the engineering properties of glass to make them less brittle, with improved toughness and durability. The basic design requirements for glass swimming pools are;

- Maximum transparency

- Robustness

- Water tightness, and

- Strength

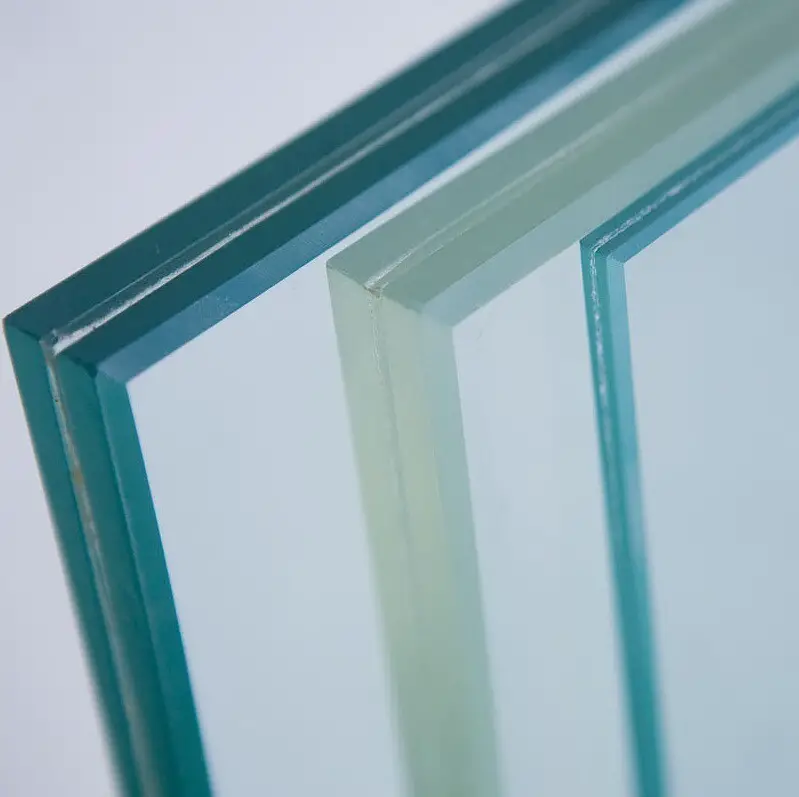

Structural glass for swimming pools is usually made of heat strengthened laminated glass, which offers shatterproof behaviour when subjected to an impact force. Multiple glass sheets laminated together are usually used in glass engineering for additional functionality in case one of the glass sheet fails.

Furthermore, different materials such as PVB (Polyvinyl butryl) or ionoplast can be used as the interlayer between different panes of glass to form laminated glass. Ionoplast interlayer, however, offers the best behaviour for glass subjected to adverse loading conditions. The safety of the people inside the pool and the people in the building should be given top priority in the design.

Structural Design of glass swimming pools

In the structural design of glass swimming pools, the thickness of the glass is determined from the anticipated hydrostatic pressure. The glass can be modelled as plate elements with simply supported boundary conditions. Glass possesses some elastic properties which allows it to regain its shape after unloading, but has no plastic properties.

This implies that fracture occurs in the material before any permanent deformation can take place. As a result, linear elastic analysis using Kirchoff’s thin plate theory is sufficient for the analysis of glass swimming pools, and the material can be idealised as a homogenous and isotropic. Failure in a glass is usually in tension because glass has good compressive strength.

Laminated glass has a modulus of elasticity several thousand times larger than the modulus of elasticity of the weakest interlayer material, PVB or ionoplast. This great mismatch makes the behaviour complex as well as analysis and modelling of laminated glass. To account for this during modelling, full relaxation of the interlayer (no cooperation between the sheets) can be assumed. This is deemed a conservative approach. Therefore, the thickness of the glass to be used in finite element modelling can be taken as;

tm = tpl √n

Where tm is the thickness to be used in modelling, tpl is the nominal thickness of each individual sheet, and n is the number of glass layers.

It is a good practice to investigate different types of support stiffness depending on the actual support conditions of the glass. Furthermore, the pool can be analysed for other conditions such as when one or more sheets are broken, and the effect evaluated.

For bottom glass panels, the self-weight of the glass and the water pressure can be applied as UDL on the surface of the glass, while for the walls, the water pressure should be applied as a triangular hydrostatic load. For suspended swimming pools, wind pressure and other anticipated forces should also be checked. After the analysis, the deflection, tensile stresses, and support reactions of the glass panes should be checked. The occurring tensile stress from the applied loading should not exceed the tensile strength capacity of the glass.

Detailing

Since every joint in a water retaining structure is a potential source of leakage, the number of joints should be minimised. The openings in the concrete floor or wall supporting the glass should be closed with a glass made of one piece. The joint between the concrete and the glass should be filled with a selected adhesive which should not react with the interlayer material. The concrete notch for the glass should be treated with primer to bind properly with the adhesive.

what should u recommend to seal likage b/n concrete and tempered glass.do u think only adhesive could stop it.

if in want to construct the swimming pool with a side of 4 meters, i want to use glass wall.

The pool size is width 4m, depth 1.5m and leght 16m

please help me calculate how thickness of glass we need to use

regards,

Design of Glass Swimming Pools highlights the striking beauty and modern appeal of transparent pool walls, offering a luxurious and visually stunning way to elevate any backyard or rooftop space.