Crack patterns can offer insight into the most likely cause of a structural failure in reinforced concrete structures. Looking at the picture in the post, what is the most likely cause of the structural failure in the building?

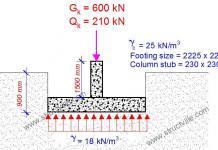

Structures are designed to satisfy ultimate and serviceability limit state requirements. Under ultimate limit state requirements, strength requirements such as bending, beam shear, punching shear, axial compression or tension, fatigue, etc are expected to be satisfied. Punching shear occurs when there is a high concentration of localised load (such as column load) on a flat element such as a flat slab or footing.

In serviceability limit state requirements, phenomena that can affect the appearance or functionality of the structure, or comfort of the occupants/users are addressed. Such phenomenon can include deflection, vibration or cracking.

The cracks looks like it was caused by a bending failure and could be because the cement did not have time to dry to its best strength to support what was there!

correct. the floor has not had enough time to cure before they placed load on it for the next floor decking

Is the rebar placement vs early concrete cure time the reason the cracking is a projection of the reinforcement?

This appears to be a shear crack directed at an angle approximately 45° which is the typical failure plain of reinforced concrete element such as a slab or a beam due to excessive shear.

It seems they should have left the props below the lower slab because concrete did not attain full strength before loading loads of the upper floor construction. The construction loads could be worst than regular loads, and as such, it seems there is an excessive shear force on the freshly constructed concrete and failure due to shear is clearly seen. Concrete is weak in shear before it attained full strength.

Looks like a combination of punching and flexural failure. Inadequate top reinforcement at the supports to counter hogging effects at that zone as well as inadequate concrete section/depth of the slab hence less strength to take the shearing forces.

Transferring the upper floor loads (and construction loads) to the lower slab (without props) is the cause of the slab failure. More so that the lower slab has wide span with no beans to safely transfer loads to the column

Agree with the shear failure crack pattern, known as punching shear. Also agree that the flats slabs are probably not underdesigned but shear failure caused due to due to the back proping not left in on ground level while the second floor is propped amd therefore supported by the 1st floor.

Lack of shoring supports on precedent floor or floors to resist the load above, exerted by the fresh concrete being poured.

The number of shoring supports depends widely on the maximum strength attained by the previous floors during the time of casting.

There is no beam to support the weight of the floor

Without reshoring below, the slab which likely was designed for a live load of 40 psi, appears to be supporting close to 100 psf. Additionally, the uncured concrete strength likely was also too low. I also wonder if the bottom reinforcing extent was too short.

it appears to be flat slab – Punching shear is cause of the cracks associated with settlement of foundation.