In geotechnical engineering, soil classification serves as a crucial framework for standardizing soil descriptions and grouping similar soils based on characteristics that profoundly influence their behaviour. These systems offer a systematic understanding of diverse soil types and their inherent properties, ultimately informing geotechnical engineering assessments and construction practices.

The primary determinant of a soil’s classification is the relative abundance of its constituent particle sizes: gravel, sand, silt, and clay. Additionally, specific attributes of the silt and clay fractions often come into play, particularly in distinguishing between these finer particle groups.

A key distinction arises from the definition of “clay” within soil classification. Unlike conventional size categorization, the term encompasses materials possessing specific mineralogical and behavioural characteristics. Clays are defined by the presence of clay minerals within the fines fraction, exhibiting distinct compositions and behaviours compared to silts and coarse-grained soils. Notably, clays inherently exhibit plasticity, the ability to remain deformed even after the removal of load. While finer particle sizes often correspond to clay minerals, some exceptions exist.

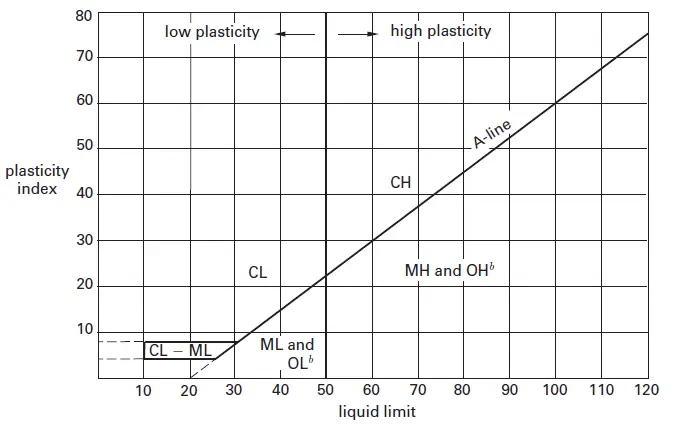

To quantify the plasticity characteristics of the fines fraction, laboratory Atterberg limit tests serve as the primary tool. These tests, including liquid limit and plasticity index measurements, provide essential data for classification purposes. However, in situations where laboratory testing is unavailable, simple “visual identification” tests can offer preliminary distinctions between clays and silts in the field.

The most popular methods of soil classification are the Unified Soil Classification System (USCS) and AASHTO Method. This article discusses the use of the USCS soil classification system and the typical range of engineering properties for different soil groups.

The Unified Soil Classification System (USCS)

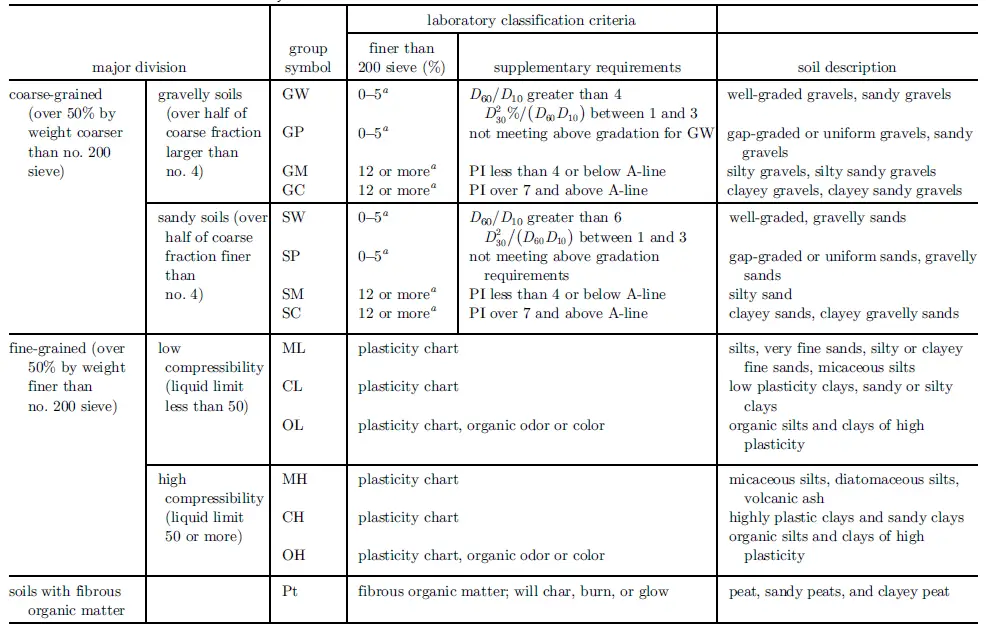

The Unified Soil Classification System (USCS), as presented below, offers a widely adopted classification framework. Similar to the AASHTO system, it utilizes grain size distribution, liquid limit, and plasticity index as its primary classification criteria.

Soils are categorized into USCS groups designated by distinct symbols and corresponding names. Each symbol comprises two letters: the first indicating the dominant particle size fraction and the second serving as a descriptive modifier. In certain instances, dual symbols are employed to accurately represent the soil’s characteristics.

Coarse-grained soils are divided into two categories: gravel soils (symbol G) and sand soils (symbol S). Sands and gravels are further subdivided into four subcategories as follows.

symbol W: well-graded, fairly clean

symbol C: significant amounts of clay

symbol P: poorly graded, fairly clean

symbol M: significant amounts of silt

Fine-grained soils are divided into three categories: inorganic silts (symbol M), inorganic clays (symbol C), and organic silts and clays (symbol O). These three are subdivided into two subcategories as follows.

symbol L: low compressibilities (LL less than 50)

symbol H: high compressibilities (LL 50 or greater)

The most recognised and common classification of soils in engineering is shown in Table 1;

| Class group Symbol | Description |

| GW | well-graded, clean gravels, gravel-sand mixtures |

| GP | poorly graded clean gravels, gravel-sand mixtures |

| GM | silty gravels, poorly graded gravel-sand silt |

| GC | clayey gravels, poorly graded gravel-sand-clay |

| SW | well-graded clean sands, gravelly sands |

| SP | poorly graded clean sands, sand-gravel mix |

| SM | silty sands, poorly graded sand-silt mix |

| SM-SC | sand-silt-clay mix with slightly plastic fines |

| SC | clayey sands, poorly graded sand-clay mix |

| ML | inorganic silts and clayey silts |

| ML-CL | mixture of organic silt and clay |

| CL | inorganic clays of low-to-medium plasticity |

| OL | organic silts and silt-clays, low plasticity |

| MH | inorganic clayey silts, elastic silts |

| CH | inorganic clays of high plasticity |

| OH | organic and silty clays |

Typical Engineering Properties of Different Soil Groups

Compaction

Soil compaction is the process of mechanically increasing the soil’s density by reducing the air void space between its particles. This densification leads to several desirable outcomes, including higher bearing capacity, reduced permeability, and improved stability.

The basic laboratory test used to determine the maximum dry density of compacted soils is the Proctor test. In construction, the maximum dry density and its corresponding optimum moisture content are obtained from the proctor test. This is used as a guide in the field to check the effectiveness of the compaction achieved.

Several approaches exist for evaluating soil compaction in the field and laboratory. Here are a few prominent methods:

- Standard Proctor Compaction Test: This classic test involves compacting soil samples in a cylindrical mould at varying moisture contents and measuring the resulting dry density. The relationship between moisture content and dry density is plotted to determine the optimum moisture content (OMC) for achieving maximum density at a specified compaction effort.

- Modified Proctor Compaction Test: This method employs higher compaction energy compared to the standard test, simulating the harsher conditions encountered in certain construction projects. The OMC and maximum dry density for the modified test are typically higher than those obtained for the standard test.

Typical values of optimum moisture content and suggested relative compactions (based on the standard Proctor test) are shown in Table 2.

| Soil Class Group Symbol | Description | Optimum Moisture Content for Compaction (Range in %) | Range of maximum dry density (kN/m3) |

| GW | well-graded, clean gravels, gravel-sand mixtures | 11–8 | 19.6 – 21.2 |

| GP | poorly graded clean gravels, gravel-sand mixtures | 14–11 | 18.0 – 19.6 |

| GM | silty gravels, poorly graded gravel-sand silt | 12–8 | 18.85 – 21.2 |

| GC | clayey gravels, poorly graded gravel-sand-clay | 14–9 | 18.0 – 20.4 |

| SW | well-graded clean sands, gravelly sands | 16–9 | 17.3 – 20.42 |

| SP | poorly graded clean sands, sand-gravel mix | 21–12 | 15.7 – 18.85 |

| SM | silty sands, poorly graded sand-silt mix | 16–11 | 17.3 – 19.63 |

| SM – SC | sand-silt-clay mix with slightly plastic fines | 15-11 | 17.3 – 20.4 |

| SC | clayey sands, poorly graded sand-clay mix | 19-11 | 16.5 – 19.63 |

| ML | inorganic silts and clayey silts | 24-12 | 15.0 – 18.85 |

| ML – CL | mixture of organic silt and clay | 22-12 | 15.7 – 18.85 |

| CL | inorganic clays of low-to-medium plasticity | 24-12 | 15.0 – 18.85 |

| OL | organic silts and silt-clays, low plasticity | 33-21 | 12.57 – 15.7 |

| MH | inorganic clayey silts, elastic silts | 40-24 | 11.0 – 14.92 |

| CH | inorganic clays of high plasticity | 36-19 | 11.78 – 16.49 |

| OH | organic and silty clays | 45-21 | 10.21 – 15.71 |

Permeability

Soil permeability describes the rate at which fluids flow through the porous matrix of soil, playing a critical role in numerous geotechnical and environmental applications. Measuring soil permeability accurately and efficiently is therefore essential for ensuring the stability and sustainability of constructed systems and mitigating potential environmental risks.

In the laboratory, the coefficient of permeability of soils is determined either through the falling head or constant head permeability tests. Typical values of the coefficient of permeability, K, are given in Table 3. Clays are considered relatively impervious, while sands and gravels are pervious. For comparison, the permeability of concrete is approximately 10-10 cm/s.

| Class group Symbol | Description | Typical coefficient of permeability (cm/s) |

| GW | well-graded, clean gravels, gravel-sand mixtures | 2.5 × 10-2 |

| GP | poorly graded clean gravels, gravel-sand mixtures | 5 × 10-2 |

| GM | silty gravels, poorly graded gravel-sand silt | > 5 × 10-7 |

| GC | clayey gravels, poorly graded gravel-sand-clay | > 5 × 10-8 |

| SW | well-graded clean sands, gravelly sands | > 5 × 10-4 |

| SP | poorly graded clean sands, sand-gravel mix | > 5 × 10-4 |

| SM | silty sands, poorly graded sand-silt mix | > 2.5 × 10-5 |

| SM-SC | sand-silt-clay mix with slightly plastic fines | > 10-6 |

| SC | clayey sands, poorly graded sand-clay mix | > 2.5 × 10-7 |

| ML | inorganic silts and clayey silts | > 5 × 10-6 |

| ML-CL | mixture of organic silt and clay | > 2.5 × 10-7 |

| CL | inorganic clays of low-to-medium plasticity | > 5 × 10-8 |

| OL | organic silts and silt-clays, low plasticity | – |

| MH | inorganic clayey silts, elastic silts | > 2.5 × 10-7 |

| CH | inorganic clays of high plasticity | > 5 × 10-8 |

| OH | organic and silty clays | – |

Shear Strength

Shear strength describes the resistance of soil to deformation and failure under applied shear stresses, playing a pivotal role in the stability of slopes, foundations, and earth-retaining structures. Understanding and accurately measuring shear strength are therefore paramount for geotechnical engineers to ensure the safety and integrity of constructed systems within the intricate dance of forces acting upon the ground.

The equation for the shear strength failure envelope is given by Coulomb’s equation, which relates the strength of the soil, S, to the normal stress on the failure plane.

S = τ + c tanφ

φ is known as the angle of internal friction and c is the cohesion intercept, a characteristic of cohesive soils.

Representative values of typical strength characteristics φ and c are given in Table 4.

| Soil Class Group Symbol | Description | Cohesion (as compacted), C (lbf/ft2(kPa)) | Cohesion (saturated), C (lbf/ft2(kPa)) | Effective Stress friction angle φ (degrees) |

| GW | well-graded, clean gravels, gravel-sand mixtures | 0 | 0 | > 38° |

| GP | poorly graded clean gravels, gravel-sand mixtures | 0 | 0 | > 37° |

| GM | silty gravels, poorly graded gravel-sand silt | – | – | > 34° |

| GC | clayey gravels, poorly graded gravel-sand-clay | – | – | > 31° |

| SW | well-graded clean sands, gravelly sands | 0 | 0 | 38° |

| SP | poorly graded clean sands, sand-gravel mix | 0 | 0 | 37° |

| SM | silty sands, poorly graded sand-silt mix | 1050 (50) | 420 (20) | 34° |

| SM – SC | sand-silt-clay mix with slightly plastic fines | 1050 (50) | 300 (14) | 33° |

| SC | clayey sands, poorly graded sand-clay mix | 1550 (74) | 230 (11) | 31° |

| ML | inorganic silts and clayey silts | 1400 (67) | 190 (9) | 32° |

| ML – CL | mixture of organic silt and clay | 1350 (65) | 460 (22) | 32° |

| CL | inorganic clays of low-to-medium plasticity | 1800 (86) | 270 (13) | 28° |

| OL | organic silts and silt-clays, low plasticity | – | – | – |

| MH | inorganic clayey silts, elastic silts | 1500 (72) | 420 (20) | 25° |

| CH | inorganic clays of high plasticity | 2150 (100) | 230 (11) | 19° |

| OH | organic and silty clays | – | – | – |

California Bearing Ratio (CBR)

California Bearing Ratio (CBR) plays a crucial role in pavement design and performance. This dimensionless index quantifies the relative strength of a soil compared to a standard crushed stone base material, serving as a critical indicator of its load-bearing capacity and susceptibility to deformation under traffic loads.

Table 5 gives typical CBR values.

| Class group Symbol | Description | CBR values (%) |

| GW | well-graded, clean gravels, gravel-sand mixtures | 40-80 |

| GP | poorly graded clean gravels, gravel-sand mixtures | 30-60 |

| GM | silty gravels, poorly graded gravel-sand silt | 20-60 |

| GC | clayey gravels, poorly graded gravel-sand-clay | 20-40 |

| SW | well-graded clean sands, gravelly sands | 20-40 |

| SP | poorly graded clean sands, sand-gravel mix | 10-40 |

| SM | silty sands, poorly graded sand-silt mix | 10-40 |

| SM-SC | sand-silt-clay mix with slightly plastic fines | 5-30 |

| SC | clayey sands, poorly graded sand-clay mix | 5-20 |

| ML | inorganic silts and clayey silts | ≤15 |

| ML-CL | mixture of organic silt and clay | – |

| CL | inorganic clays of low-to-medium plasticity | ≤15 |

| OL | organic silts and silt-clays, low plasticity | ≤5 |

| MH | inorganic clayey silts, elastic silts | ≤10 |

| CH | inorganic clays of high plasticity | ≤15 |

| OH | organic and silty clays | ≤5 |

Plate Bearing Value

The Plate Bearing Value (PBV) test offers insight into the soil’s ability to withstand applied loads. This critical in-situ technique sheds light on a soil’s bearing capacity, a fundamental property governing its suitability for supporting foundations, pavements, and other load-bearing structures.

The PBV test measures the load-deformation response of soil under a circular steel plate subjected to increasing pressure. The test quantifies the bearing capacity through the PBV itself, defined as the pressure at which the soil exhibits a predetermined, typically 12.5mm, deflection. Essentially, the PBV reflects the soil’s resistance to deformation under applied loads, providing a crucial indicator of its suitability for supporting structures.

The subgrade modulus (modulus of subgrade reaction), k, is the slope of the line (in psi per inch) in the loading range encountered by the soil. Typical values are shown in Table 6.

| Class group Symbol | Description | Modulus of subgrade reaction k (psi/in (kPa/mm))) |

| GW | well-graded, clean gravels, gravel-sand mixtures | 300–500 (80–140) |

| GP | poorly graded clean gravels, gravel-sand mixtures | 250–400 (68–110) |

| GM | silty gravels, poorly graded gravel-sand silt | 100–400 (27–110) |

| GC | clayey gravels, poorly graded gravel-sand-clay | 100–300 (27–80) |

| SW | well-graded clean sands, gravelly sands | 200–300 (54–80) |

| SP | poorly graded clean sands, sand-gravel mix | 200–300 (54–80) |

| SM | silty sands, poorly graded sand-silt mix | 100–300 (27–80) |

| SM-SC | sand-silt-clay mix with slightly plastic fines | 100–300 (27–80) |

| SC | clayey sands, poorly graded sand-clay mix | 100–300 (27–80) |

| ML | inorganic silts and clayey silts | 100–200 (27–54) |

| ML-CL | mixture of organic silt and clay | – |

| CL | inorganic clays of low-to-medium plasticity | 50–200 (14–54) |

| OL | organic silts and silt-clays, low plasticity | 50–100 (14–27) |

| MH | inorganic clayey silts, elastic silts | 50–100 (14–27) |

| CH | inorganic clays of high plasticity | 50–150 (14–41) |

| OH | organic and silty clays | 25–100 (6.8–27) |