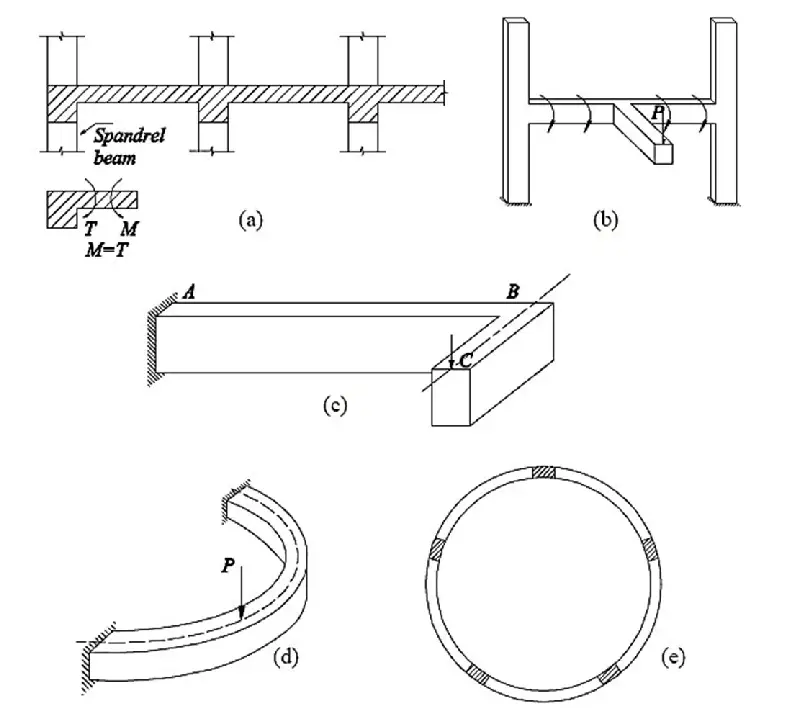

A full torsional design covering the ultimate and serviceability limit states is required when the equilibrium of a structure is dependent on the torsional resistance of the member. Reinforced concrete (RC) beams are subjected to torsion when the point of application of loads does not coincide with the shear centre of the beams. This can be due to the arrangement of the beams or the loading pattern as can be found in circular or canopy beams.

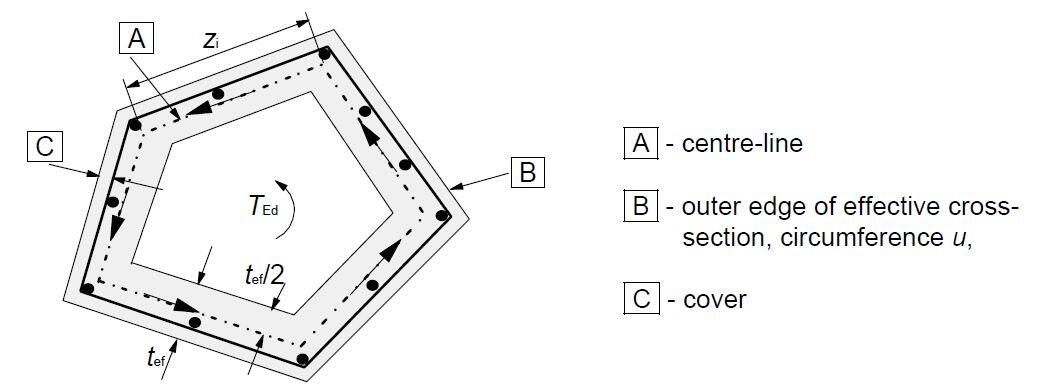

According to clause 6.3.1(3) of EN 1992-1:2004, the torsional resistance of a section may be calculated on the basis of a thin-walled closed section, in which equilibrium is satisfied by a closed shear flow. Solid sections may be modelled by equivalent thin-walled sections. Complex shapes, such as T-sections, may be divided into a series of sub-sections, each of which is modelled as an equivalent thin-walled section, and the total torsional resistance taken as the sum of the capacities of the individual elements.

In Eurocode 2, the shear stress in a wall of a section subject to a pure torsional moment may be calculated from:

τt,itef,i = TEd/2Ak

The shear force VEd,i in a wall i due to torsion is given by:

VEd,i = τt,itef,izi

where;

TEd is the applied design torsion

Ak is the area enclosed by the centre-lines of the connecting walls, including inner hollow areas.

τt,i is the torsional shear stress in wall i

tef,i is the effective wall thickness. It may be taken as A/u, but should not be taken as less than twice the distance between edge and centre of the longitudinal reinforcement. For hollow sections the real thickness is an upper limit

A is the total area of the cross-section within the outer circumference, including inner hollow areas

u is the outer circumference of the cross-section

zi is the side length of wall i defined by the distance between the intersection points with the adjacent walls

The required cross-sectional area of the longitudinal reinforcement for torsion ΣAsl may be calculated from Expression (6.28) of EC2:

ΣAsl/fyd = TEdcotθ/2Ak

where;

uk is the perimeter of the area Ak

fyd is the design yield stress of the longitudinal reinforcement Asl

θ is the angle of compression struts

According to clause 6.3.2(4) of EC2, the maximum resistance of a member subjected to torsion and shear is limited by the capacity of the concrete struts. In order not to exceed this resistance the following condition should be satisfied:

TEd/TRd,max + VEd/VRd,max ≤ 1.0 (Equation 6.29, EC2)

where:

TEd is the design torsional moment

VEd is the design transverse force

TRd,max is the design torsional resistance moment = TRd,max = 2ναcwfcdAktef,isinθcosθ

VRd,max is the maximum design shear resistance according to Expressions (6.9) of EC2

Worked Example

Carry out a full torsional design of a rectangular reinforced concrete (RC) beam subjected to an ultimate torsional moment of 55 kNm, and shear force of 225 kN. The section is 600 x 400 mm, and reinforcement of 4H25 (As,prov = 1964 mm2) has been provided to resist the bending moment. (fck = 28 N/mm2; fyk = 500 N/mm2)

Solution

Concrete strength class; C28/35 ×γα

Characteristic compressive cylinder strength;fck = 28 N/mm2

Partial factor for concrete -Table 2.1N; γC = 1.50

Compression chord stress coefficient – cl.6.2.3(3); αcw = 1.00

Compressive strength coefficient – cl.3.1.6(1); αcc = 0.85

Design compressive concrete strength – exp.3.15; fcd = αcc × fck/γC = 15.9 N/mm2

Compressive strength coefficient – cl.3.1.6(1); αccw = 1.00

Design compressive concrete strength – exp.3.15; fcwd = αccw × fck/γC = 18.7 N/mm2

Tensile strength coefficient – cl.3.1.6(2); αct = 1.00

Mean value of axial strength of conc. – cl.3.1.6(2); fctm = 0.3 N/mm2 × (fck)2/3 = 2.77 N/mm2

Characteristic axial strength of conc. (5% factile); fctk,0.05 = 0.7 × fctm = 1.94 N/mm2

Design axial strength of concrete; fct,d = act × fctk,0.05/γC = 1.29 N/mm2

Reinforcement details

Characteristic yield strength of reinforcement; fyk = 500 N/mm2

Partial factor for reinforcing steel – Table 2.1N; γS = 1.15

Design yield strength of reinforcement; fyd = fyk/γS = 435 N/mm2

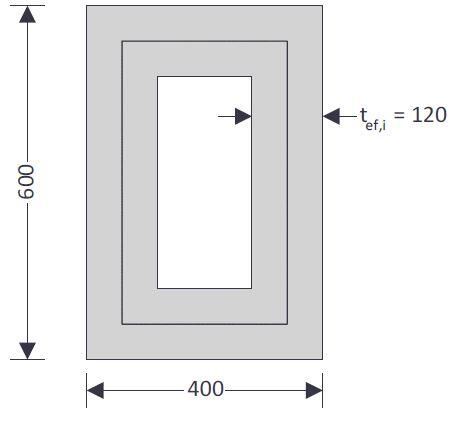

Beam dimensions

Section width; b = 400 mm

Section depth; h = 600 mm

Design forces

Maximum design torsional moment; TEd,max = 55.0 kNm

Maximum design shear force; VEd,max = 225.0 kN

Area of design longitudinal reinforcement; Asl = 1964 mm2

Effective depth to outer layer; d = 450 mm

Torsional resistance (Section 6.3, EC2)

Effective thickness of walls – cl.6.3.2(1); tef,i = (b × h) / (2 × (b + h)) = 120 mm

Area enclosed by centre lines of walls – cl.6.3.2(1); Ak = (b – tef,i) × (h – tef,i) = 134400 mm2

Perimeter – cl.6.3.2(3); Uk = 2 × ((b – tef,i) + (h – tef,i)) = 1520 mm

Strength reduction factor; v1 = 0.6 × (1 – fck / 250 N/mm2) = 0.533

Design shear stress; vt,Ed = VEd,max / (b × d) = 1.250 N/mm2

Torsional shear stress in wall – exp.6.26; tt,Ed = TEd,max / (2 × Ak × tef,i) = 1.705 N/mm2

Concrete strut angle;qt = min[45°, max(0.5 × Asin(min(2 × (vt,Ed / 0.9 + tt,Ed) / (αcw × fcwd × v1), 1)), 21.8°)] = 21.8°

Max design value of torsional resist. mnt – exp 6.30; TRd,max = 2 × v1 × αcw × fcd × Ak × tef,i × sin(qt) × cos(qt) = 94.0 kNm

Max design shear force – exp.6.9; VRdt,max = acw × b × 0.9 × d × v1 × fcwd / (cot(qt) + tan(qt)) = 555.6 kN

Interaction formulae – exp.6.29; TEd,max / TRd,max + VEd,max / VRdt,max = 0.990

PASS – concrete section is adequate

Torsional and shear resistance of the concrete alone

Maximum torsional resist moment with no shear reinf. – cl.6.3.2(5); TRd,c = 2 × Ak × fct,d × tef,i = 41.6 kNm

Shear resistance constant – cl.6.2.2; CRd,c = 0.18/γC = 0.120

Reinforcement ratio – cl.6.2.2; rl = min(Asl/(d × b), 0.02) = 0.011

Effective depth factor – cl.6.2.2; kv = min(1 + √(200mm/d), 2) = 1.667

Minimum shear stress; vmin = 0.035 N/mm2 × kv3/2 × (fck / 1N/mm2)0.5 = 0.4 N/mm2

Design value for shear resistance – exp.6.2.a; VRd,c = max(CRd,c × kv × 1N/mm2 × (100 × rl × fck/1N/mm2)1/3 × b × d, vmin × b × d) = 112.5 kN

Interaction formulae – exp.6.31; TEd,max / TRd,c + VEd,max / VRd,c = 3.320

Therefore, additional reinforcement required

Required torsional reinforcement

Required area of add. long. reinf. for torsion (6.28); Asl,req = TEd,max × Uk × cot(qt) / (2 × Ak × fyd) = 1788 mm2

Provide 10Y16 side bars (5 on each face) for torsion (Asprov = 2010 mm2)

The longitudinal bars should be arranged so there is at least one bar at each corner with the other spaced around the periphery of the links at a spacing of 350mm or less (cl.9.2.3(4))

Required shear reinforcement for torsion (one leg); Asw,req = TEd,max / (2 × Ak × fyd × cot(qt)) = 188 mm2/m

Maximum spacing for torsion shear reinforcement; sw,max = min(Uk/8, b, h) = 190 mm

Provide 2 legs H10@175 c/c as torsion/shear reinforcement

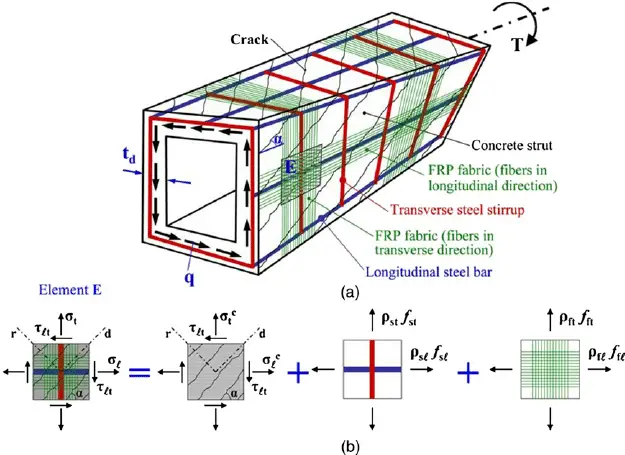

[Featured Image Credit] Chai H.K., Majeed A.A., Allawi A.A (2015): Torsional Analysis of Multicell Concrete Box Girders Strengthened with CFRP Using a Modified Softened Truss Model. ASCE Journal of Bridge Engineering, 20(8) https://doi.org/10.1061/(ASCE)BE.1943-5592.0000621

To download this article in PDF format, click HERE