According to EN 1992-1-1:2004, lightweight concrete is concrete having a closed structure and a density of not more than 2200 kg/m3 consisting of or containing a proportion of artificial or natural lightweight aggregates having a particle density of less than 2000 kg/m3. By having a closed structure, the implication is that the concrete must not be aerated either autoclaved or cured for the requirements stated to apply.

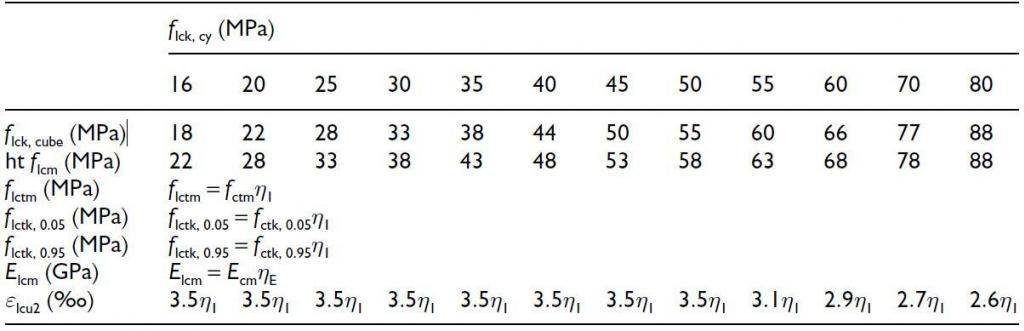

The requirements for normal-weight concrete are generally applicable to lightweight concrete unless specifically varied as described in Chapter 11 of EN 1992-1-1:2004. In general, where strength values originating from Table 3.1 of EC2 are used in Expressions, those values have to be replaced by the corresponding values for lightweight concrete, given in Table 11.3.1 OF EC 2.

Lightweight concrete offers the advantage of considerably reducing the dead load of a structure. According to ASTM 331-05, structural lightweight concrete should not have 28 days compressive strength of less than 17 MPa. Structural lightweight concrete can be applied in;

- Floors in steel frame buildings (lightweight concrete on fire-rated steel deck assemblies)

- Concrete frame buildings & parking structures (all types, including post-tensioned floor systems)

- Bridge decks, piers & AASHTO girders

- Specified density concrete, etc

To manufacture lightweight concrete, natural or artificial lightweight aggregates could be used (to form a closed structure). Alternatively, the concrete could be aerated or produced with no fines (open structure).

The main natural lightweight aggregates used for production of concrete are;

1. Diatomite

2. Pumice

3. Scoria

4. Volcanic cinders

5. Tuff

Artificial lightweight aggregates can be manufactured by heating raw materials such as shales, clay, and pellets in a kiln at a temperature of about 1200 ℃. Alternatively, molten blast furnace slag or clinker aggregates can be used.

The following symbols are used specially for lightweight concrete:

LC the strength classes of lightweight aggregate concrete are preceded by the symbol LC

ηE is a conversion factor for calculating the modulus of elasticity

η1 is a coefficient for determining tensile strength

η2 is a coefficient for determining creep coefficient

η3 is a coefficient for determining drying shrinkage

ρ is the oven-dry density of lightweight aggregate concrete in kg/m3

For the mechanical properties an additional subscript l (lightweight) is used.

Density Classes

Six density classes are identified for lightweight concrete in EN 206-1. This is reproduced in the table below. The table gives corresponding densities for plain and reinforced concrete with normal percentages of reinforcement which may be used for design purposes in calculating self-weight or imposed permanent loading. Alternatively, the density may be specified as a target value during mix design.

| Density class | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 |

| Range of density | 801 – 1000 | 1001 – 1200 | 1201 – 1400 | 1401 – 1600 | 1601 – 1800 | 180- 2000 |

| Nominal design density (kg/m3): Plain concrete | 1050 | 1250 | 1450 | 1650 | 1850 | 2050 |

| Nominal design density (kg/m3): Reinforced concrete | 1150 | 1350 | 1550 | 1750 | 1950 | 2150 |

Many properties of lightweight concrete are related to its density ρ. The coefficient;

η1 = 0.4 + 0.6ρ/2200

is used to modify the relevant property of normal-weight concrete. In this expression, ρ refers to the upper limit of the density for the relevant density class in accordance with the table above.

An estimate of the mean values of the secant modulus Elcm for lightweight concrete may be obtained by multiplying the values in Table 3.1 of EC2, for normal density concrete, by the following coefficient:

ηE = (ρ/2200)2

The strength classes and properties associated with lightweight concrete are shown in the Table below;

Design compressive strength

The value of the design compressive strength is;

flcd = αlccflck/γc

The recommended value in the code for αlcc is 0.85. The UK National Annex proposes to adopt the same value.

Similarly, the value of the design tensile strength is

flctd = αlctflctk/γc

with αlct = 0.85.