Slurry cut-off walls or slurry trenches are excavations that are made under the ground and filled with engineered slurries for the purpose of preventing the movement of groundwater into an excavation or construction area. Apart from acting as barriers to groundwater movement, slurry walls can also be used as barriers to the flow of leachate or contaminated groundwater. They can also be used to prevent the migration of gases into an area in a soil formation.

Slurry cut-off walls have been used for a long time in the control of groundwater during construction. In principle, engineered slurries are placed into a narrow excavation that forms the boundary of the area that needs to be barricaded from groundwater flow. The slurry will exert a hydrostatic pressure on the face of the excavation which will keep it stable from collapse while at the same time, prevent the movement of groundwater into the area of interest. Slurry cut-off walls are applicable to all kinds of soils but are more applicable to sandy soil deposits where the coefficient of permeability is high. Sandy soils also have more potential for collapse when excavations in it are unsupported.

Excavations for slurry trenches can be carried out using hoe excavators and can extend very deep to the impermeable stratum on the soil profile. Therefore, the construction will require adequate planning for workspace, safety, and operation of heavy construction equipment.

Bentonite slurry is the most commonly used material for filling slurry trenches. Bentonite slurry is formed by mixing bentonite clay with water, after which the colloidal mixture is pumped into the excavation. As a result, no additional shoring or bracing is required in slurry cut-off walls (see design of braced cuts).

One of the requirements of slurry trenches is that the lateral pressure exerted by the slurry on the excavation face must be equal to or greater than the lateral pressure from the soil and ground water. The properties of the slurry which influence the design of slurry trench walls are;

- Density of the slurry

- Gel strength (thixotropy) of the slurry

- Viscosity of the slurry

- pH of the slurry

The aim of this article is to show how to determine the required minimum density of slurry that will ensure the lateral stability of an excavation using a worked example.

Solved Problem

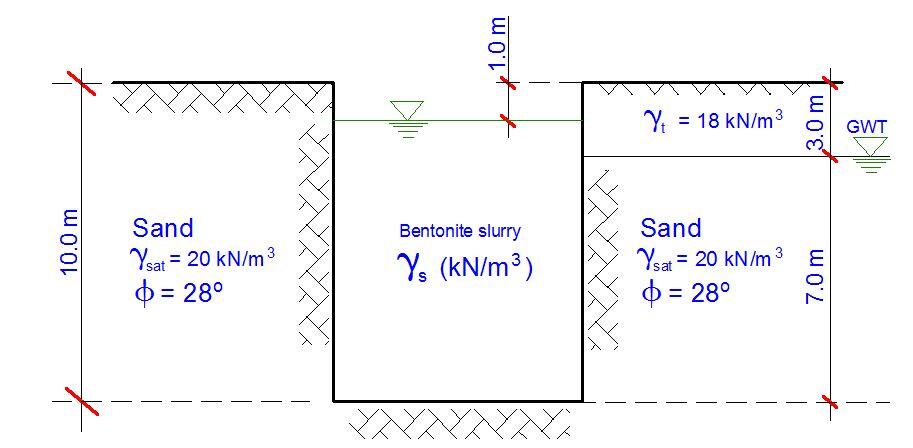

For the slurry cut-off wall shown above, calculate the minimum density of the slurry in the trench to prevent the wall of the excavation from sliding.

Solution

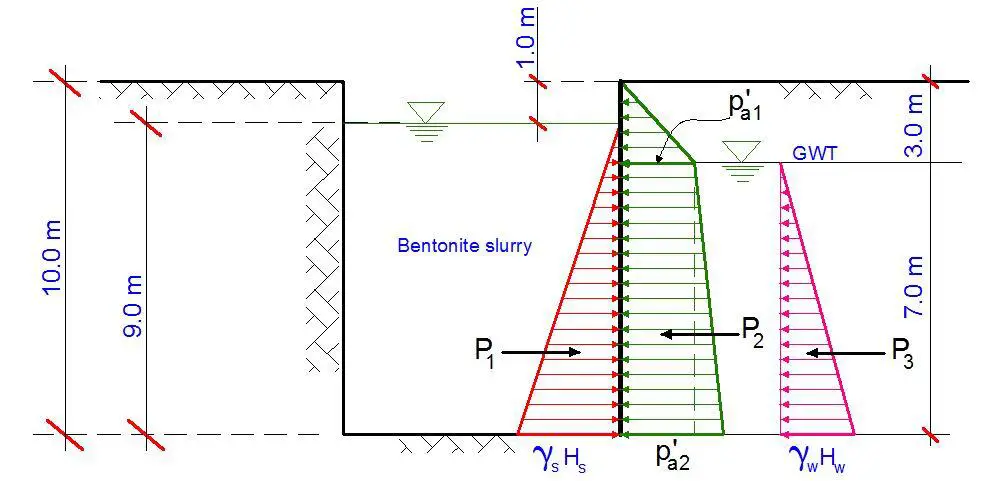

The solution to this problem is based on the principle of lateral earth pressure. The lateral pressure exerted by the slurry must be equal to or greater than the lateral earth and groundwater pressure at the face of the excavation. The free-body diagram of the pressures are shown below;

For stability of the excavation;

P1 = P2 + P3

Using Rankine’s earth pressure theory, the coefficient of active earth pressure is given by;

kA = (1 – sinΦ)/(1 + sinΦ) = (1 – sin 28)/(1 + sin 28) = 0.361

P1 = ½γsHs2 = (0.5 × γs × 92) = 40.5γs

P3 = ½γwHw2 = (0.5 × 9.81 × 72) = 240.345 kN/m

p’a1 = kaγth1 = 0.361 × 18 × 3 = 19.494 kN/m2

p’a2 = ka[γth1 + (γsat – γw)hw] = 0.361[18 × 3 + (20 – 9.81) × 7] = 45.244 kN/m2

P2 = ½(p’a1)h1 + ½(p’a1 + p’a2)hw = (0.5 × 19.494 × 3) + 0.5( 19.494 + 45.244) × 7 = 29.241 + 226.583 = 255.824 kN/m

P1 = P2 + P3

40.5γs = 255.824 + 240.345

On solving;

γs = 12.25 kN/m3

Therefore, among other factors the slurry must have a minimum density of 12.25 kN/m3.

Nice one Boss