Cost is often a major determiner of decision-making on projects. Therefore, for all civil engineering works, it is required to know the probable construction cost before the project’s commencement. This is known as the estimated cost, which comprises the cost of labour, materials, equipment, and other general overhead costs. The construction and cost comparison of rectangular and trapezoidal drains can be an important consideration during highway design.

In a previous article, determining the best hydraulic section of roadside drains was discussed whereby a particular peak discharge was designed, resulting in rectangular and trapezoidal cross-sections. However, the cost comparison of both cross-sections will be discussed in this article to determine which cross-sections will result in greater savings on cost.

The details of both drain cross-sections are provided below. However, it must be noted that it is assumed that the construction is in-situ, and the cost comparison is based on 1m length of the drain cross-sections. Furthermore, the cost of labour is proportional to the quantity of materials.

Construction Process of Reinforced Concrete Drains

The procedures for the construction of reinforced concrete drains are stated below:

Marking of alignment: This involves a surveyor marking out the alignment for the trench to be dug. This alignment includes horizontal and vertical alignment. The projection of the drain in the horizontal plane is termed as the horizontal alignment, while the projection in the vertical plane is termed the vertical alignment. Survey instruments are used in this operation.

Excavation: After the surveyors have marked out the trench alignment, the depth is also marked out. Excavation is then carried out through the use of manual labour or mechanical means by the use of excavating machine.

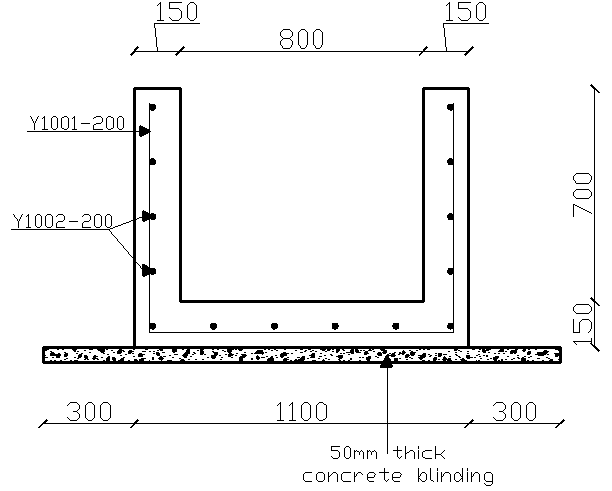

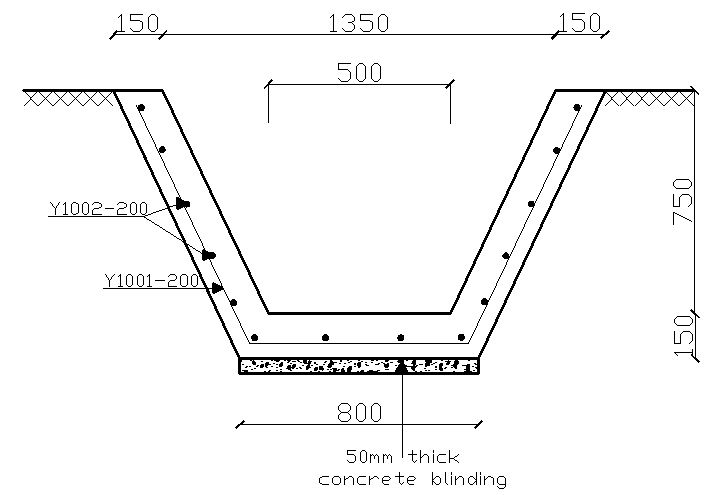

Concrete blinding: This is the process of pouring a thin layer of concrete over the bed of the trench to seal in the underlying soil material and prevent dirt and mud from interfering with the drain structure. It is also done to correct any irregularities in the bed of the excavated surface, and to provide smooth, level and regular surface to receive the concrete base. The concrete blinding is a mass concreting and usually 50mm in thickness.

Positioning of reinforcements: U-shape or trapezoidal-shape rebars, as the case may be, are usually placed in position on the blinded surface at the designed spacing. Furthermore, the rebars are positioned with the aid of concrete biscuit to create a concrete cover. It must be ensured that the center of the base aligns with the center alignment provided by the surveyor in order to have a uniform alignment.

Concrete base: After the positioning of rebars, the next step is to cast the concrete base. Usually, a concrete base of 150mm in thickness is cast on the blinded bed of the drain. A guiding panel or formwork is placed into position to guide in casting the concrete base to achieve a uniform alignment base edge, thickness, width, and to manage the concrete while pouring.

Concrete wall: After the casting of the base, and setting and hardening of the concrete, the formwork for the drain walls are positioned to allow for the casting of the wall. The fair-finished panels to be used as formwork should be lubricated, clipped and prepared to receive the concrete. After casting, setting and hardening of the walls, the panels are removed and the concrete is cured.

Backfilling and compaction: After the casting of the drain walls, the excavated portion left beside the drain is backfilled and compacted to avoid settlement of the backfill.

Cost Analysis of Rectangular Drain

Excavation

Volume of soil = (1.1 + 0.6) × (0.05 + 0.15 + 0.7) × 1 = 1.53 m3

Unit cost of excavation = ₦1,500 per m3

Cost of excavation = 1.53 x 1,500 = ₦2,295

Concrete in blinding

Volume of concrete = 0.05 × 1.7 × 1 = 0.085 m3

Unit cost of concrete = ₦55,000

Cost of concrete material = 0.085 × 55,000 = ₦4,675

Concrete in drain

Volume of concrete = [(1.1 × 0.15) + 2(0.7 × 0.15)] x 1 = 0.375 m3

Unit cost of concrete = ₦55,000

Cost of concrete material = 0.375 × 55,000 = ₦20,625

Reinforcement

Bar Mark 1 = 6 × 2.6 × 0.617 = 9.626 kg

Bar Mark 2 = 14 × 1 × 0.617 = 8.638 kg

Total weight of rebar = 9.626 + 8.638 = 18.264 kg

Unit cost of rebar = ₦ 450

Cost of rebar = 18.264 x 450 = ₦ 8,220

Formwork

Base = 2(0.15) × 1 = 0.3 m2

Walls = 2(0.7+0.7) × 1 = 2.8 m2

Total area of formwork required = 0.3 + 2.8 = 3.1m2

Unit cost of formwork = ₦5,400 (marine plywood)

Total cost of formwork = 3.1 x 5,400 = ₦16,740

Cost Analysis of Trapezoidal Drain

Excavation

Volume of soil = [0.5(0.8 + 1.65) × 0.95] × 1 = 1.164m3

Unit cost of excavation = ₦1,500

Cost of excavation = 1.164 × 1,500 = ₦1,745

Concrete in blinding

Volume of concrete = 0.05 × 0.8 × 1 = 0.04m3

Unit cost of concrete = ₦55,000

Cost of concrete material = 0.04 × 55,000 = ₦2,200

Concrete on drain

Volume of concrete = [0.5(1.65 + 0.8) × 0.9] – [0.5(0.5 + 1.35) × 0.75] = (1.1025 – 0.69375) × 1 = 0.409m3

Unit cost of concrete = ₦55,000

Cost of concrete material = 0.409 × 55,000 = ₦22,495

Reinforcement

Bar Mark 1 = 6 × 2.6 × 0.617 = 9.626 kg

Bar Mark 2 = 14 × 1 × 0.617 = 8.638 kg

Total weight of rebar = 9.626 + 8.638 = 18.264 kg

Unit cost of rebar = ₦450

Cost of rebar = 18.264 x 450 = ₦8,220

Formwork

Walls = 2(0.865) × 1 = 1.73m2

Unit cost of formwork = ₦5,400

Total cost of formwork = 1.73 × 5,400 = ₦9,345

The table below shows the cost comparison of the rectangular and trapezoidal drains;

| Cost component | Rectangular Section | Trapezoidal Section | % reduction or increment |

| Excavation | ₦2,295 | ₦1,745 | – 23.97% |

| Concrete in blinding | ₦4,675 | ₦2,200 | – 52.94% |

| Concrete in drain | ₦20,625 | ₦22,495 | + 9.07% |

| Reinforcement | ₦8,220 | ₦8,220 | — |

| Formwork | ₦16,740 | ₦9,345 | – 44.18% |

| Total | ₦52,555 | ₦44,005 | – 16.27% |

Conclusion

The article has discussed the cost comparison of rectangular and trapezoidal drain cross-sections per meter run for a particular peak discharge. From the cost analysis, it can be deduced that the cost of concrete in drain required for the trapezoidal drain is 9.07% higher than that of the rectangular drain. However, there are significant reductions of 23.97% in excavation cost, 52.94% in concrete blinding cost, and 44.18% in formwork cost for the trapezoidal drain over the rectangular cross-section.

Furthermore, there is an overall cost reduction of 16.27% if the choice of drain cross-section is trapezoidal. Similarly, suppose the labour cost is directly related to the quantity of materials. In that case, adopting the trapezoidal cross-section is expected to result in savings on the cost compared to a rectangular cross-section. This justifies that trapezoidal cross-sections are usually the most economical, provided there is a right-of-way (ROW).

This great it is of good benefit to We the up coming Engineer

Great I love this

Hw much is drainage gutter of 600 by 600 cost per m² in Nigeria