Waffle slabs are reinforced concrete slabs that are normally employed for large-span construction. They can be described as the equivalent of 2-way spanning solid slabs but with a ribbed slab system spanning in both directions. In waffle slabs, the grids run in two directions to provide support for the floor.

Waffle slabs have a flat top and a surface resembling a grid made of concrete joists on the bottom. After the concrete has set and cured, the waffle moulds are removed to create the grid. Due to the rigidity of the waffle slab, this form of structure is suggested for buildings like manufacturing plants and laboratories that require little vibration.

Additionally, waffle slabs are utilized in structures like theatres and train stations that call for expansive open areas. Waffle slabs may be more expensive than other types of slabs because they require intricate formwork, but depending on the project and the amount of concrete used, they may be less expensive to construct.

The design concept of waffle slabs is similar to that of ribbed slabs, with the difference being that waffle slabs have ribs spanning in both directions, and the coefficients used for analysing the slab are similar to those used for a two-way restrained slab. Waffle slabs are supported on beams or columns, where the support zones are made to be uniformly thick.

Design Example of Waffle Slab

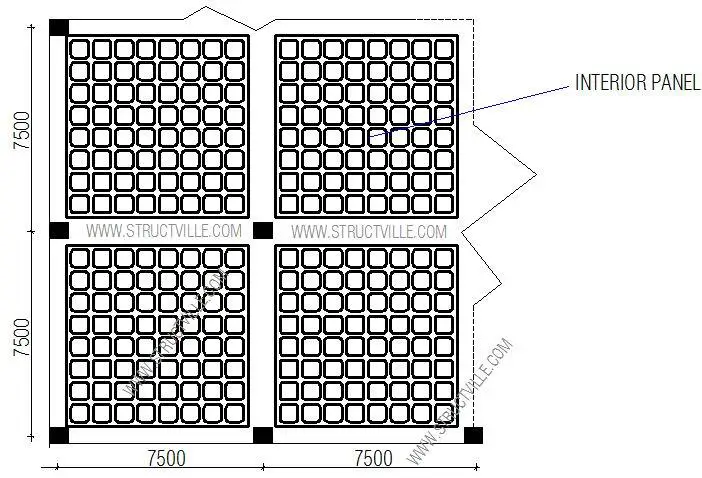

A church building has a square grid of 7.5m x 7.5m of waffle slab, and is to support an imposed load of 5 kN/m2, design an interior panel of the waffle slab, and a supporting beam. fck = 30 Mpa, fyk = 500 Mpa. The design will be done according to Eurocode 2 (EN 1992-1-1:2004).

For details of waffle mould, see details of technical data sheet.

Solution

From basic span/effective depth ratio of 26, the trial depth of slab to be adopted = 7500/26 = 288 mm

From the table, let us select the following mould details;

Mould height = 225 mm

Top layer thickness = 75 mm

Total height of slab = 300 mm

Average rib width = 176 mm

Load Analysis

Self weight of concrete = 5.2 kN/m2 (see technical data sheet)

Finishes = 1.2 kN/m2

Partition allowance = 1.5 kN/m2

Total permanent action = 7.9 kN/m2

Imposed load = 5 kN/m2

At ultimate limit state = 1.35gk + 1.5qk = 1.35(7.9) + 1.5(5) = 18.165 kN/m2

Load per rib = 0.9 × 18.165 = 16.35 kN/m2

Analysis of the slab

Treating as all sides fixed:

k = Ly/Lx = 1.0

Span coefficient = +0.024

Support coefficients = -0.032

Design of the span

Designing the span as a T-beam;

MEd = 0.024 × 16.35 × 7.52 = 22.07 kN.m

Effective depth (d) = h – Cnom – ϕ/2 – ϕlinks

Assuming ϕ12 mm bars will be employed for the main bars, and ϕ10 mm bars for the stirrups (links)

d = 300 – 25 – (12/2) -10 = 259 mm

k = MEd/(fckbd2) = (22.07 × 106)/(30 × 500 × 2592) = 0.0219

Since k < 0.167, no compression reinforcement required

z = d[0.5+ √(0.25 – 0.882k)]

k’ = 0.0219

z = d[0.5+ √((0.25 – 0.882(0.0219))] = 0.95d = 246.05 mm

Depth to neutral axis x = 2.5(d – z) = 2.5(259 – 246.05) = 32.375 mm < 1.25hf (93.75 mm)

Therefore, we design rib as a rectangular section

Area of tension reinforcement As1 = MEd / (0.87fyk z)

As1 = MEd / (0.87fyk z) = (22.07 × 106) / (0.87 × 500 × 0.95 × 259) = 206 mm2

Provide 2H12 Bot (ASprov = 226 mm2)

Check for deflection

ρ = As,req /bd = 206 / (900 × 259) = 0.0008837

ρ0 = reference reinforcement ratio = 10-3√(fck) = 10-3√(30) = 0.00547

Since ρ ≤ ρ0;

L/d = k [11 + 1.5√(fck) ρ0/ρ + 3.2√(fck) (ρ0/ρ – 1)(3⁄2)]

k = 1.5 (continuous system)

L/d = 1.5 [11 + 1.5√(30) × (0.00547/0.0008837) + 3.2√(30) × [(0.00547 / 0.0008837) – 1](3⁄2)]

L/d = 1.5[11 + 50.855 + 207.227] = 269.082

βs = (500 Asprov)/(fyk Asreq) = (500 × 226) / (500 × 206) = 1.09

beff/bw = 900/176 = 5.11

Therefore multiply basic length/effective depth ratio by 0.8

Therefore limiting L/d = 1.09 × 0.8 × 269.082 = 234.639

Actual L/d = 7500/259 = 28.96

Since Actual L/d (28.96) < Limiting L/d (234.639), deflection is satisfactory.

Design of Supports;

MEd = 0.032 × 16.35 × 7.52 = 29.43 kN.m

k = MEd/(fckbd2) = (29.43 × 106)/(30 × 176 × 2592) = 0.083

Since k < 0.167, no compression reinforcement required

z = d[0.5+ √(0.25 – 0.882k)]

k = 0.083

z = d[0.5+ √((0.25 – 0.882(0.083))] = 0.92d

Area of tension reinforcement As1 = MEd / (0.87fyk z)

As1 = MEd / (0.87fyk z) = (29.43 × 106) / (0.87 × 500 × 0.92 × 259) = 283 mm2

Provide 3H12 TOP (ASprov = 339 mm2)

Shear Design

Maximum shear force in the rib

VEd = 0.33 × 16.35 × 7.5 = 40.466 kN/m

VRd,c = [CRd,c.k.(100ρ1 fck)(1/3) + k1.σcp]bw.d ≥ (Vmin + k1.σcp) bw.d

CRd,c = 0.18/γc = 0.18/1.5 = 0.12

k = 1 + √(200/d) = 1 + √(200/259) = 1.88 < 2.0, therefore, k = 1.88

Vmin = 0.035k(3/2) fck0.5

Vmin = 0.035 × (1.88)1.5 × 300.5 = 0.494 N/mm2

ρ1 = As/bd = 339/(176 × 259) = 0.00743 < 0.02; Therefore take 0.00743

VRd,c = [0.12 × 1.88 (100 × 0.00743 × 30 )(1/3)] × 176 × 259 = 28941.534 N = 228.94 kN

Since VRd,c (28.94 kN) < VEd (40.466 kN), shear reinforcement is required.

The compression capacity of the compression strut (VRd,max) assuming θ = 21.8° (cot θ = 2.5)

VRd,max = (bw.z.v1.fcd) / (cotθ + tanθ)

V1 = 0.6(1 – fck/250) = 0.6(1 – 30/250) = 0.528

fcd = (αcc fck) / γc = (0.85 × 30) / 1.5 = 17 N/mm2

Let z = 0.9d

VRd,max = [(176 × 0.9 × 259 × 0.528 × 17) / (2.5 + 0.4)] × 10-3 = 126.981 kN

Since < VEd < VRd,c < VRd,max

Hence Asw / S = VEd / (0.87 Fyk z cot θ) = 40466 / (0.87 × 500 × 0.9 × 259 × 2.5 ) = 0.159

Minimum shear reinforcement;

Asw / S = ρw,min × bw × sinα (α = 90° for vertical links)

ρw,min = (0.08 × √(fck)) / fyk = (0.08 × √30) / 500 = 0.000876

Asw/Smin = 0.000876 × 176 × 1 = 0.154

Maximum spacing of shear links = 0.75d = 0.75 × 259 = 194.25 mm

Provide H8mm @ 175 mm c/c as shear links (Asw / S = 0.574)

Slab Topping

A142 BRC Mesh can be provided or H8 @ 250mm c/c

Watch out for design of supporting beams…

Thank you for this information!

Ps.

1. For various reasons I cannot access the information in the link for: “technical data sheet attached.”

…. if you can send me this information on the email address: relu59@yahoo.com.

2. I have to solve urgently a floor with dimensions 7.80 m x 24.20 m leaning on a structure of load-bearing masonry with the thickness of walls of 0.45 m. Are you willing to give me some advice or even technical solutions ?

Thank you in advance.

The maximum opening of the waffle roof is such that it can be divided into three important factors in the structure. These three factors mean structural safety, cost, and aesthetics of the plan. These three factors are very important for engineers, contractors and even buyers. To be able to execute our structure with a roof that is responsive to high spans. We can also save on building costs by removing extra columns. It is an important thing in construction.

according to which code this design had done

If I may ask. why did you use 5.20 kN/m2 for self weight and is said to be according to the technical data sheet. on the data sheet I see 4.05 kN/m2 for dead load.

very good

Hi there, could you link the design calcs you have done for supporting beams?