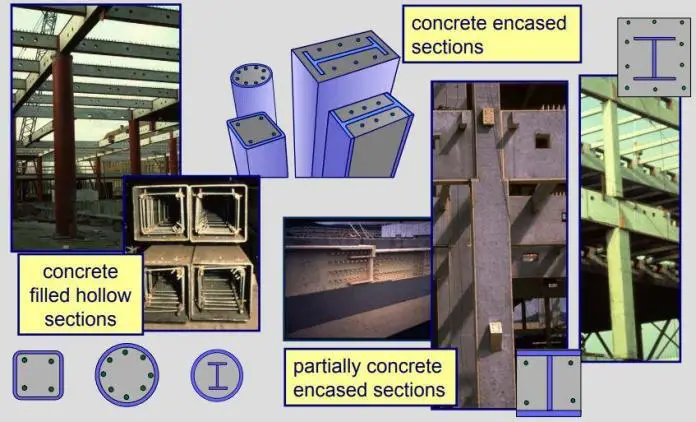

Composite sections of concrete and steel have a lot of advantages, especially in the structural performance and fire resistance of a building. For columns and other compression members, they usually appear as steel-reinforced concrete columns (SRC) or as concrete-filled steel tubes. In this article, we are going to consider the structural design of concrete encased H-section subjected to concentric axial load using Eurocode 4 and BS 5950.

According to BS 5950, the steps to design composite steel columns are as follows;

- Determine ultimate axial load Fc.

- Select trial section and check if it is non-slender.

- Determine rx, ry and Ag from steel tables.

- Determine effective lengths, LEX and LEY

- Calculate slenderness ratios, λEX (= LEX/rx) and λEY (= LEX/ry).

- Select suitable strut curves from Table

- Determine compressive strength, pc

- Calculate compression resistance of member, Pc = Agpc.

- Check Fc ≤ Pc . If unsatisfactory return to 2.

According to Eurocode 4, the simplified steps to design encased steel columns subjected to axial load are as follows;

- Determine the ultimate axial load on the column NEd

- Select a trial section and determine its properties

- Obtain the buckling length of the column L

- Obtain the effective flexural stiffness (EI)eff of the composite section

- Calculate the plastic resistance to compression of the composite section Npl,Rk

- Calculate the relative slenderness of the section (λ) using Euler’s critical load

- Choose the appropriate buckling curve and calculate the corresponding reduction factor χ

- Multiply the plastic resistance to compression with the reduction factor to obtain the buckling resistance of the section Nb,Rd

- Check if NEd < Nb,Rd else return to step 2.

Solved Example

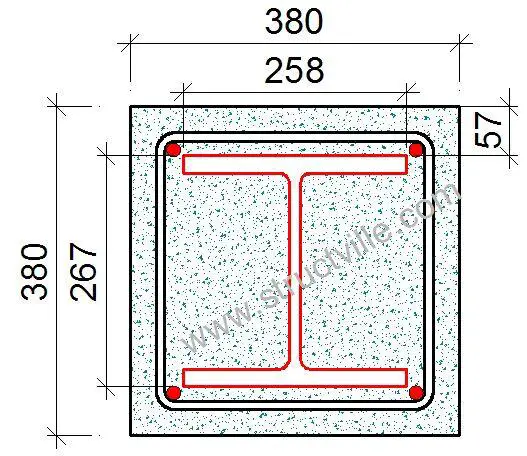

Verify the capacity of UC 254 x 254 x 107 in grade S275 steel encased in a concrete section of 380 x 380 mm to resist a characteristic permanent axial force of 1900 kN and variable axial force of 800 kN using concrete grade C25/30. Column is 3m long and considered pinned at both ends (Area of reinforcement provided = 4H16 (804 mm2 , fyk = 500 N/ mm2).

Solution by BS 5950

The ultimate axial load on the column is given by;

Fc = 1.4Gk + 1.6Qk = 1.4(1900) + 1.6(800) = 3940 kN

Properties of the UC section from Blue Book

Area of UC section (Ag) = 13600 mm2

Radius of gyration (rx) = 113 mm

Radius of gyration (ry) = 65.9 mm

Design strength (py) = 265 N/mm2 (since thickness of flange T = 20.5 mm)

Effective length (LE) = 3.0 m

Effective length

Check that the effective length of column (L = 3000 mm) does not exceed the least of:

(i) 40bc = 40 × 380 = 15200 mm

(ii) 100bc2/dc = (100 × 3802)/380 = 38000 mm

(iii) 250ry = 250 × 65.9 = 16475 mm OK

Radii of gyration for the cased section

For the cased section rx is the same as for UC section = 113 mm

For the cased section ry = 0.2bc = 0.2 × 380 = 76 mm but not greater than 0.2(B + 150) = 0.2(258.8 + 150) = 81.76 mm and not less than that for the uncased section (= 65.9 mm)

Hence ry = 76 mm and rx = 113 mm

Slenderness ratio

λEX = LEX/rx = (3000/113) = 26.548

λEY = LEY/ry = (3000/76) = 39.47

Compressive strength

The relevant compressive strength values for buckling about the x–x axis are obtained from Table 24(b)

of BS 5950 and from Table 24(c) of BS 5950 for bending about the y–y axis.

For λEX = 26.548 and py = 265 N/mm2, pc = 256.45 N/mm2

For λEY = 39.47 and py = 265 N/mm2, pc = 230.848 N/mm2

The compression resistance of the column is therefore given by;

Pc = (Ag + 0.45fcuAc/py)pc

Where:

Ag = 13600 mm2

fcu = 30 N/mm2

Ac = bcdc = 380 x 380 = 144400 mm2

pc = 265 N/mm2

pc = 230.848 N/mm2

Pc = [13600 + (0.45 x 30 x 144400)/265] x 230.848 x 10-3 = 4837.703 kN

Check that Pc is not greater than the short strut capacity, Pcs , given by;

Pcs = (Ag + 0.25fcuAc /py)py = [13600 + (0.25 x 30 x 144400)/265] x 265 x 10-3 = 4687 kN (this is less than Pc , therefore, take Pcs)

Fc /Pc = 3940 /4687 = 0.840 < 1.0 Okay

Design by Eurocode 4

At ultimate limit state;

NEd = 1.35Gk + 1.5Qk = 1.35(1900) + 1.5(800) = 3765 kN

Effective length of the column L = 3000 mm

Area of UC section (Aa) = 13600 mm2

Radius of gyration (iy) = 113 mm

Radius of gyration (iz) = 65.9 mm

Design strength (fy) = 265 N/mm2 (since thickness of flange T = 20.5 mm)

Iy = 17500 cm4

Iz = 5930 cm4

E = 210000 N/mm2

The plastic resistance to compression Npl,Rk = Aa.fy + 0.85Acfck + Asfyk

Aa = 13600 mm2

fy = 265 N/mm2

Ac = 380 x 380= 144400 mm2

fck = 25 N/mm2

As = 804 mm2

fyk = 500 N/mm2

Npl,Rk = [(13600 x 265) + (0.85 x 144400 x 25) + (804 x 500)] x 10-3 = 7074.5 kN

The relative slenderness λi = ( Npl,Rk / Ncr )0.5

Ncr,i = π2(EI)eff,i /L2

(EI)eff,i = EaIa + 0.6EcmIc + EsIs

Ea = Es = Elastic modulus of the structural steel and reinforcement respectively = 210000 N/mm2

Ia = Moment of inertia of structural steel in the relevant axis

Ecm = Modulus of elasticity of concrete = 22(fck/10)0.3 (GPa) = 28960 N/mm2 (see Table 3.1 of Eurocode 2)

Ic = moment of inertia of the uncracked concrete section = bd3/12 = (380 x 3803)/12 = 17376.133 x 105 mm4

Is = moment of inertia of the reinforcement = πD4/64 = (π x 164)/64 = 3216.99 mm4 (for four bars = 4 x 3216.99) = 12867.96 mm4

Hence;

(EI)eff,y = (210000 x 17500 x 104) + (0.6 x 28960 x 17376.133 x 105) + (210000 x 12876.96) = 6.69455 x 1013 N.mm2

(EI)eff,z = (210000 x 5930 x 104) + (0.6 x 28960 x 17376.133 x 105) + (210000 x 12876.96) = 4.26485 x 1013 N.mm2

Ncr,y = [(π2 x 6.69455 x 1013) /30002] x 10-3 = 73413.955 kN

Ncr,z = [(π2 x 4.26485 x 1013)/30002] x 10-3 = 46769.313 kN

λy = (Npl,Rk / Ncr,y)0.5 = (7074.5/73413.955)0.5 = 0.310

λz = (Npl,Rk / Ncr,z)0.5 = (7074.5/46769.313)0.5 = 0.389

Check h/b ratio = 266.7/258.8 = 1.0305 < 1.2, and tf < 100 mm (Table 6.2 EN 1993-1-1:2005)

Therefore buckling curve b is appropriate for y-y axis, and buckling curve c for z-z axis. The imperfection factor for buckling curve b α = 0.34 and curve c = 0.49 (Table 6.1)

Φ = 0.5 [1 + α(λ – 0.2) + λ2]

Φy = 0.5 [1 + 0.34 (0.310 – 0.2) + 0.3102] = 0.567

Φz = 0.5 [1 + 0.49 (0.389 – 0.2) + 0.3892 ] = 0.622

X = 1/[Φ + √(Φ2 – λ2)]

Xy = 1/[0.567 + √(0.5672 – 0.3102)] = 0.959

Xz = 1/( 0.622 + √(0.6222 – 0.3892)) = 0.903

Therefore Nb,Rd = (Xz Npl,Rk)= (0.903 x 7074.5) = 6388.685 kN

NEd /Nb,Rd = 3765/6388.685 = 0.589 < 1.0 kN Okay