Site managers are saddled with the responsibility of making material requisition and ensuring that construction progresses without too many glitches. One of the major causes of delay in construction is the unavailability of materials on site. Therefore a site engineer is expected to have very quick tips on how to estimate the quantity of materials required to execute a given item of work.

In this article, we are going to provide a basic quantity estimate guide for common construction materials that are used on site. The list is not exhaustive and will be updated from time to time.

(a) Quantity Estimation Guide for Concrete Works

The materials that are required for the production of normal weight concrete are cement, sand, coarse aggregates, and water. For normal strength concrete, the quantity of cement varies with the concrete grade, while the quantity of sand and coarse aggregate remains approximately constant. To estimate the quantity of materials required for concrete works, the first step is to calculate the volume of concrete required for the job.

For slabs; the volume of concrete required (m3) = Area of the floor slab (m2) × thickness of slab (m)

For beams; the volume of concrete required (m3) = Depth of beam (m) × width of beam (m) × length of the beam (m)

For columns; the volume of concrete required (m3) = length of column (m) × width of column (m) × height of column (m)

For instance, for a (230 x 230)mm column in a duplex, the volume of concrete required is 0.16 m3 (i.e 0.23 m × 0.23 m × 3m = 0.16 m3) assuming that the storey height is 3 m. This volume can be multiplied by the number of columns in the building to obtain the total volume of concrete required for casting all the columns in the building.

After obtaining the volume of concrete required, the quantity of materials required for the production of one cubic metre of concrete can be estimated as follows;

(i) 7 bags (350 kg) of cement is required to produce one cubic metre (1m3) of grade 25 concrete

(ii) 1200 kg (1.2 tonnes) of sand is required to produce one cubic metre (1m3) of grade 25 concrete

(iii) 1400 kg (1.4 tonnes) of granite is required to produce one cubic metre (1m3) of grade 25 concrete

(iv) 175 – 210 litres of water is required to produce one cubic metre (1m3) of grade 25 concrete

The quantities listed above require no additional allowance for waste.

Read Also…

How to price concrete works in Nigeria

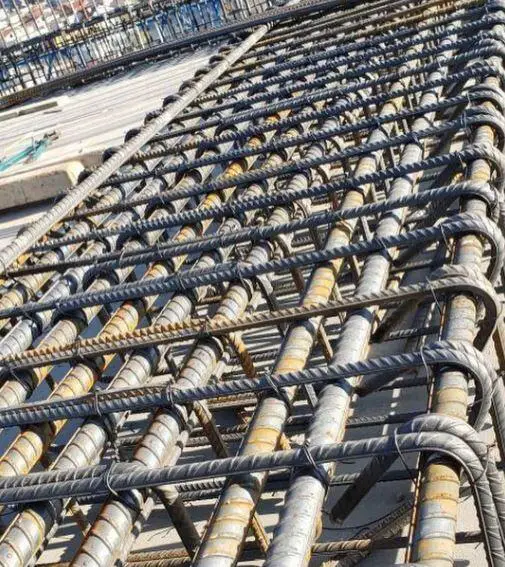

(b) Quantity Estimation Guide for Reinforcement Works

The quantity of reinforcements required can vary considerably depending on the structural design output of the structure. Therefore, it is important to refer to the reinforcement detailing and bar bending schedule for quantity estimation. It is also important to note that the bar bending schedule issued by structural engineers does not take into account offcuts and wastage. It is therefore, important to consider the propriety of bar bending schedule for construction purposes. More often than not, contractors prepare their own bar bending schedule (taking offcuts into account) before placing an order.

Reinforcements are usually quantified by weight (kg or tonnes), which can be converted to length (reinforcements are usually supplied per 12 m length). The unit weight of different sizes of reinforcements are as follows;

| Diameter of bar (mm) | 8 | 10 | 12 | 16 | 20 | 25 |

| Unit weight (kg/m) | 0.395 | 0.616 | 0.888 | 1.579 | 2.466 | 3.854 |

Reinforcement Quantity Estimation in the Floor Slab of a Duplex

In a floor slab of about 4-5 bedrooms duplex (200 – 250 m2 of floor slab area), the reinforcement requirement is about 2.5 – 4.0 tonnes of Y12 mm (main reinforcements) and 0.3 to 0.6 tonnes of Y10 mm as distribution bars. The exact quantity is determined from the design drawings.

In the absence of design drawings and an idea is needed about the probable cost of reinforcement for a floor slab, the following relationship can be used for slabs of moderate span;

- 12.5 kg of Y12mm bottom reinforcement is needed per square metre (1 m2) of slab

- 20% to 30% of the weight of Y12mm (in kg) provided at the bottom is needed at the top (hogging areas)

- 10% to 15% of the weight of Y12mm (in kg) provided at the bottom is needed as Y10mm (distribution bar of hogging reinforcements)

- About 12 kg of binding wire is required to tie 1 tonne of reinforcement

Example

Estimate the quantity of reinforcement needed to construct a 250 m2 of moderately spanned floor slab in a duplex.

Solution

Quantity of bottom reinforcement required = 12.5 kg × 250 = 3125 kg = 3.125 tonnes of Y12 mm

Quantity of top reinforcement required (using 25% of bottom reinforcement) = 0.25 × 3125 = 781 kg = 0.781 tonnes of Y12 mm

Quantity of distribution bars required (using 12% of bottom reinforcement) = 0.12 × 3125 = 375 kg = 0.375 tonnes of Y10 mm

The total quantity of reinforcement required = 4.281 tonnes

Quantity of binding wire required = 12 × 4.281 = 52 kg

Note that this quantity can considerably vary based on the design result. Therefore, the quantity presented here is just a rough idea, and the reinforcements are assumed to be spaced at 150 – 175 mm c/c. This may however be an uneconomical design, but we need a rough idea of the cost, right? When the reinforcement is spaced at 200 mm c/c, 10.7 kg per square metre can be assumed for the bottom reinforcements.

Reinforcement Quantity Estimation in the Beams of a Duplex

In the absence of design results, the quantity of reinforcement required in beams of moderate spans (say equal to or less than 4m) in a duplex can be estimated as follows;

- 7.9 – 9.5 kg of Y16mm per linear metre of a beam

- 2.5 kg of Y8mm per linear metre of a beam as links/stirrups

- 3.55 kg of Y12 mm per linear metre of a lintel

- 2.5 kg of Y8mm per linear metre of a lintel as links/stirrups

Please note that the quantity stated above is not guaranteed to satisfy structural requirements. Consult a structural engineer for this purpose.

Example

Estimate the quantity of floor beam reinforcement required in a moderate duplex if the total length of all the floor beams in the building is 130 m.

Solution

Quantity of Y16 mm bars required = 9.5 × 130 = 1235 kg = 1.235 tonnes of Y16 mm

Quantity of links reinforcement required = 2.5 × 130 = 325 kg = 0.325 tonnes of Y8 mm

Reinforcement Quantity Estimation in the Columns of a Duplex

In the absence of design results, the following can be used to estimate the quantity of reinforcement in columns of 230 x 230 mm dimensions in a duplex (one suspended floor only).

- 25 kg of Y16mm per 3m high column

- 5.33 kg of Y8mm per 3m column as links/stirrups

Note that this quantity can considerably vary based on the design result.

Example

Estimate the quantity of reinforcement required to construct 25 number of 230 x 230 columns in the ground floor of a duplex. All spans in the building are moderate.

Solution

Quantity of Y16mm required = 25 × 25 = 625 kg (0.625 tonnes of Y16 mm)

Quantity of Y8mm required = 25 × 5.33 = 133.25 (0.133 tonnes of Y8 mm)

(c) Quantity Estimation Guide for Blockwork

The following quantity estimation guide can be used for the estimation of the block work in a building;

- 10 blocks are required to lay one square metre (1m2) of block wall

- 1 bag of cement is required to lay 50 blocks (9 inches block)

- 320 kg of sharp sand is required to lay 50 blocks (9 inches block)

(d) Quantity Estimation Guide for Plastering

For a 12 mm thick 1:4 mix ratio of plastering work, the following relationship applies;

- The volume of plastering mortar required per square metre (1 m2) of wall = 0.012 m3

- 4.7 kg of cement is required to plaster one square metre (1 m2) of wall

- 20.7 kg of plaster sand is required to plaster one square metre (1 m2) of wall

From the on going, we can say that 1 bag of cement can plaster approximately 10 m2 of wall.

(e) Quantity Estimation Guide for Formwork

For the soffit formwork of a slab;

- 12 pieces of 1″ x 12″ x 12′ plank formwork is required to cover an area of ten square metres (10 m2)

- 4 pieces of marine board (1.2 m x 2.4m) is required to cover an area of ten square metres (10 m2)

1 piece of 2″ x 3″ x 12′ softwood is required per square meter (1 m2) of slab

(f) Miscellaneous

The weight of one bag of cement is 50 kg

The volume of one bag of cement = 0.034 m3

The volume of a standard builder’s wheelbarrow = 0.065 m3

The volume of one standard head pan is = 0.0175 m3

These quantities are true when the headpan/wheelbarrow is unheaped

We normally assume the following on site;

- One bag of cement = 2 head pans

- 1 wheelbarrow = 4 headpans

Highly Educative and Useful for Site Managers

Wonderful and concise information. Great job sir

What a nice write up, keep it up Engr.

This is so nice and motivating. But my unction here is how can we arrive at the fact that 7bags of cement makes 1m3 of concrete. I tried to calculate but what I got is 1bags. Thank you.

Very useful information for site management

Educative piece