Columns are the most noticeable feature of a structure and are often used to support gravity loads transmitted from the floors or roofs of buildings. Strength, economy, adaptability, good fire resistance, and robustness are all advantages of in-situ reinforced concrete columns. During the design of columns, sound engineering judgement is often needed to balance their location, size, and shape with horizontal element spans and economy.

Circular columns are often designed for the ultimate axial load, NEd, ultimate design moment, MEd, and ultimate shear force VEd. For internal columns, moments may generally be assumed to be nominal when compared with external columns.

Due to their uniform strength in all directions, circular concrete columns are frequently employed in the design of pilings and bridge piers, and are very convenient for seismically active areas. Furthermore, it is much easier to confine the concrete using special reinforcement in circular columns than in other shapes.

Theoretical Background

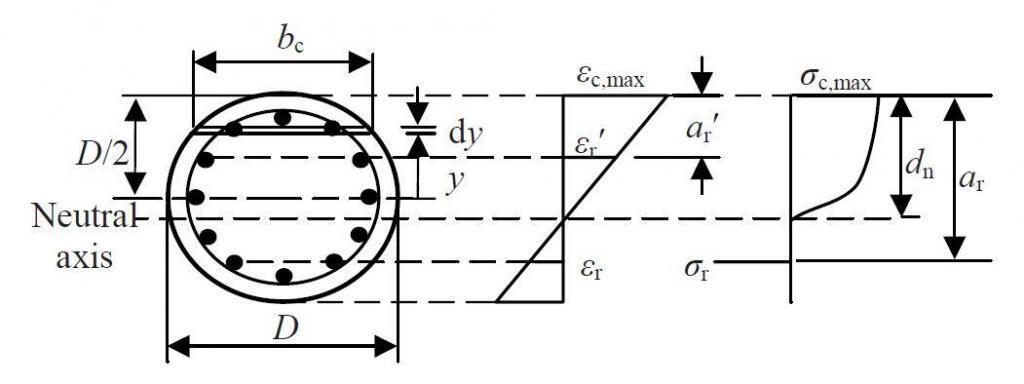

When the neutral axis remains within a section, the basic equations for a section’s equilibrium under combined bending and axial load are as follows:

NRd = favbx + ∑fsAs ——- (1)

MRd = favbx(h/2 – βx) + ∑fsAs(h/2 – di) ——- (2)

In Equation (2), moments have been taken about the concrete section’s centroid. The summation signs represent a summation of all layers of reinforcement in the section. Tensile stresses must be considered negative when summing them up. di is the distance between the section’s compressive face and the ith layer of reinforcement.

We can substitute 0.459fck for fav and 0.416 for β by assuming that the partial safety factors for the steel and concrete are 1.15 and 1.5, respectively, and that αcc is 0.85. For cases in which the neutral axis remains within the section, the resulting equations are rigorous. More complex expressions must be resolved when the entire section is in compression for the following situations;

(1) the portion of the parabolic curve cut off by the bottom of the section and

(2) the reduction in the ultimate strain at the compressive face

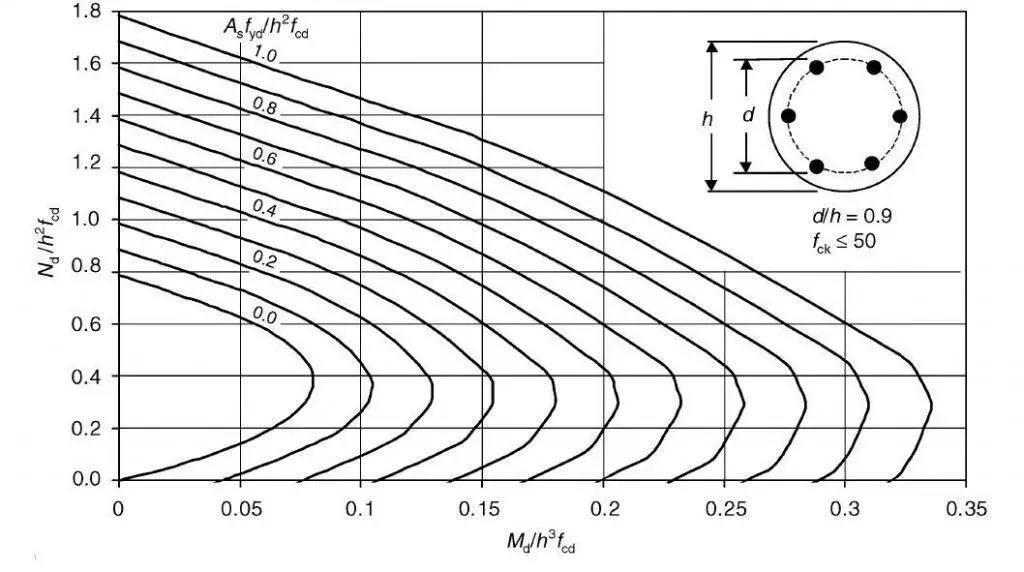

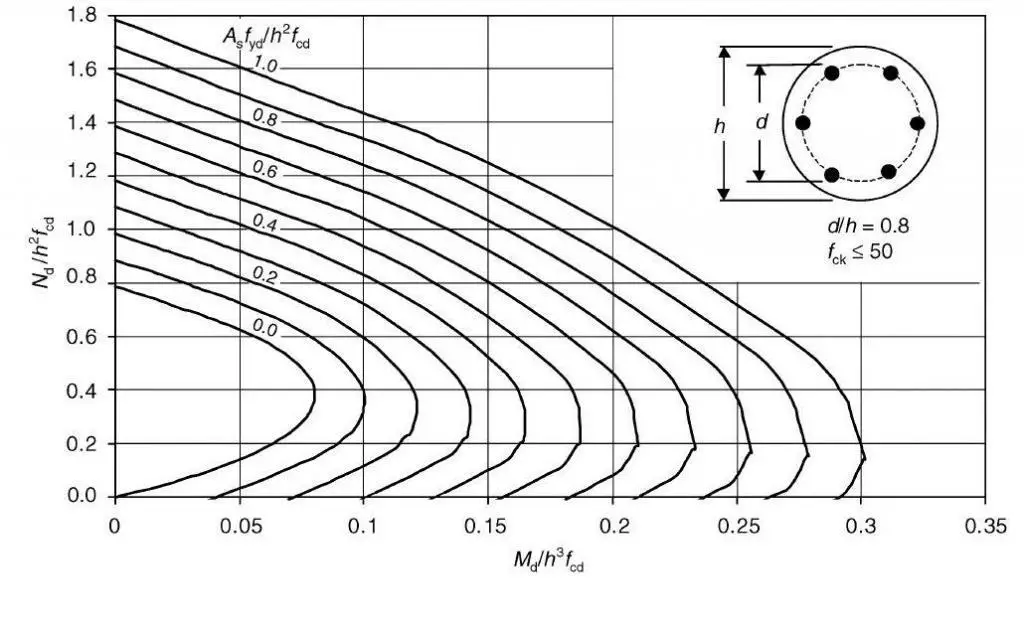

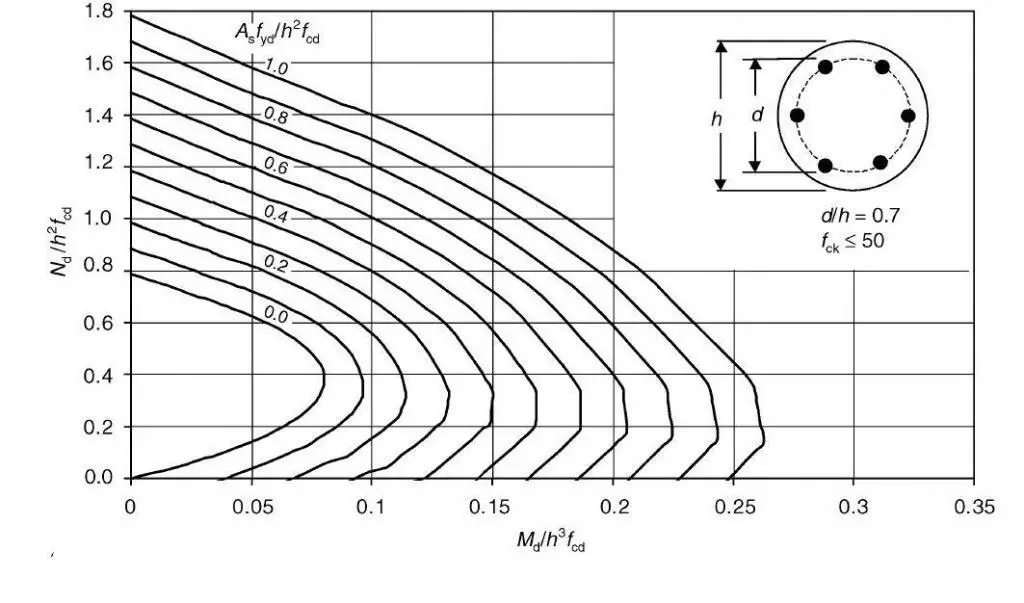

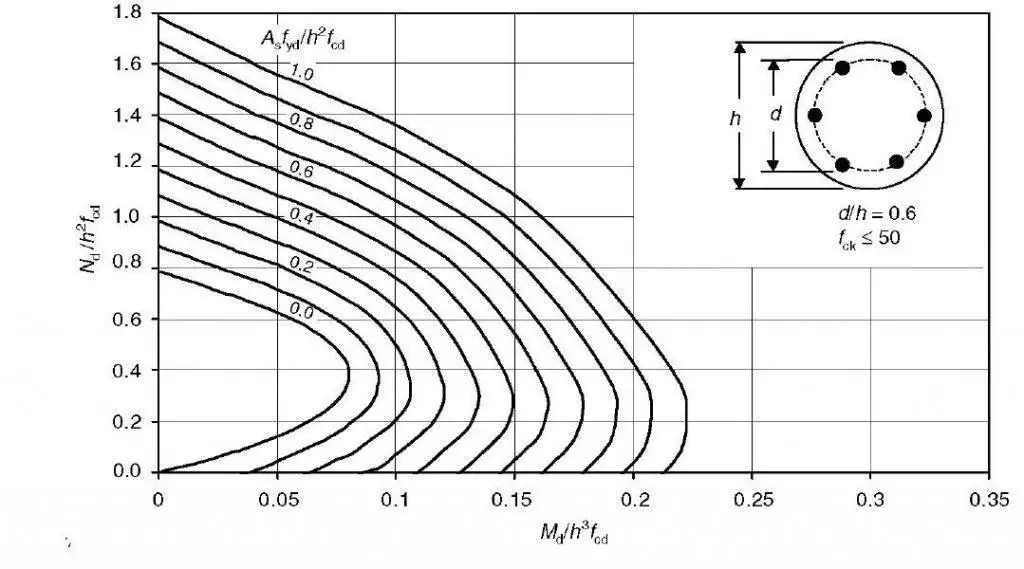

Additionally, for situations when the concrete strength is greater than 50 N/mm2, more complicated equations are required. Because of how complex the resulting equations are, it is inappropriate to present them here. Using design charts is an easier method.

Some design charts for circular columns are given below. Since six reinforcing bars are the minimum that can be employed in a circular section, this is the assumption made while drawing the charts. It is discovered that no specific arrangement of reinforcement in relation to the axis of bending will always result in minimal strength. As a result, the charts are produced to provide a lower bound envelope to the interaction diagrams for different bar arrangements.

Design Example of RC Circular Columns

Verify the resistance of 6H25 bars to withstand the loads in a column of a high-rise building in accordance with EN1992-1-1 incorporating Corrigendum January 2008 and the UK national annex. The design information is as follows;

Height of column = 5m

fck = C25/30

fyk = 500 MPa

Diameter of column = 400 mm

Design axial load; NEd = 1500.0 kN

Moment about y-axis at top; Mtopy = 66.0 kNm

Moment about y-axis at bottom; Mbtmy = 32.0 kNm

Moment about z-axis at top; Mtopz = 25.0 kNm

Moment about z-axis at bottom; Mbtmz = 5.5 kNm

Column geometry

Overall diameter; h = 400 mm

Clear height between restraints about y-axis; ly = 5000 mm

Clear height between restraints about z-axis; lz = 5000 mm

Stability in the z direction; Braced

Stability in the y direction; Braced

Concrete details

Concrete strength class; C25/30

Partial safety factor for concrete (2.4.2.4(1)); γC = 1.50

Coefficient αcc (3.1.6(1)); αcc = 0.85

Maximum aggregate size; dg = 20 mm

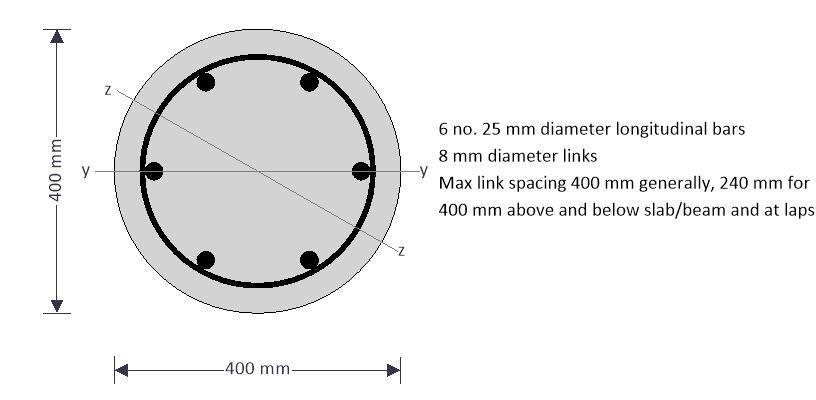

Reinforcement details

Nominal cover to links; cnom = 35 mm

Longitudinal bar diameter; φ= 25 mm

Link diameter; φv = 8 mm

Total number of longitudinal bars; N = 6

Area of longitudinal reinforcement; As = N × (π × φ2 / 4) = 2945 mm2

Characteristic yield strength; fyk = 500 N/mm2

Partial safety factor for reinft (2.4.2.4(1)); γS = 1.15

Modulus of elasticity of reinft (3.2.7(4)); Es = 200 kN/mm2

Fire resistance details

Fire resistance period; R = 60 min

Exposure to fire; Exposed on more than one side

Ratio of fire design axial load to design resistance; mfi = 0.70

Axial load and bending moments from frame analysis

Design axial load; NEd = 1500.0 kN

Moment about y axis at top; Mtopy = 66.0 kNm

Moment about y axis at bottom; Mbtmy = 32.0 kNm

Moment about z axis at top; Mtopz = 25.0 kNm

Moment about z axis at bottom; Mbtmz = 5.5 kNm

Beam/slab concrete strength class; C25/30

Beams/slabs providing rotational restraint about y axis

Depth on side A; hA1y = 500 mm

Width on side A; bA1y = 300 mm

Length on side A; lA1y = 4500 mm

Depth on side B; hB1y = 500 mm

Width on side B; bB1y = 300 mm

Length on side B; lB1y = 6000 mm

Beams providing rotational restraint about z axis

Depth on side A; hA1z = 500 mm

Width on side A; bA1z = 300 mm

Length on side A; lA1z = 3500 mm

Depth on side B; hB1z = 500 mm

Width on side B; bB1z = 300 mm

Length on side B; lB1z = 3500 mm

Relative flexibility end 2 for buckling about y axis; k2y = 1000.000

Relative flexibility end 2 for buckling about z axis; k2z = 1000.000

Calculated column properties

Area of concrete; Ac = π × h2 / 4 = 125664 mm2

Column characteristic comp. cylinder strength; fck = 25 N/mm2

Column design comp. strength (3.1.6(1)); fcd = acc × fck / γC = 14.2 N/mm2

Column mean value of cyl. strength (Table 3.1); fcm = fck + 8 MPa = 33.0 N/mm2

Column secant modulus of elasticity (Table 3.1); Ecm = 22000 MPa × (fcm / 10 MPa)0.3 = 31.5 kN/mm2

Beam/slab characteristic comp. cylinder strength; fck_b = 25 N/mm2

Beam/slab mean value of cyl. strength (3.1.6(1)); fcm_b = fck_b + 8 MPa = 33.0 N/mm2

Beam/slab secant mod. of elasticity (Table 3.1); Ecm_b = 22000 MPa × (fcm_b / 10 MPa)0.3 = 31.5 kN/mm2

Rectangular stress block factors

Depth factor (3.1.7(3)); λsb = 0.8

Stress factor (3.1.7(3)); η = 0.9

Strain limits

Compression strain limit (Table 3.1); εcu3 = 0.00350

Pure compression strain limit (Table 3.1); εc3 = 0.00175

Design yield strength (3.2.7(2)); fyd = fyk / γS = 434.8 N/mm2

Check nominal cover for fire and bond requirements

Min. cover reqd for bond (to links) (4.4.1.2(3)); cmin,b = max(φv, φ – φv) = 17 mm

Min axis distance for fire (EN1992-1-2 T 5.2a); afi = 40 mm

Allowance for deviations from min cover (4.4.1.3); Dcdev = 10 mm

Min allowable nominal cover; cnom_min = max(afi – φ/2 – φv, cmin,b + Dcdev) = 27.0 mm

PASS – the nominal cover is greater than the minimum required

Effective depth and inertia of bars for bending about y axis

For the purposes of determining the bending capacity and interaction diagrams in this calculation, bending about the y axis is taken to be when there are two furthest equidistant bars on each side of the column centreline. Bending about the z axis is taken to be when there is one furthest bar on each side of the column centreline.

Area per bar; Abar = π × φ2 / 4 = 491 mm2

Radial dist from column centre to longitudinal bar; rl = h/2 – cnom – φv – φ/2 = 144.5 mm

Subtended angle between adjacent bars; α = (360 deg) / N = 60.0 deg

Layer 1; dy1 = h/2 + rl × cos(α/2) = 325.1 mm

2nd moment of area of reinft about y axis; Iy1 = 2 × Abar × (dy1 – h/2)2 = 1537 cm4

Layer 2; dy2 = h / 2 + rl × cos[(2 – 1) × a + a/2] = 200.0 mm

2nd moment of area of reinft about y axis; Iy2 = 2 × Abar × (dy2 – h/2)2 = 0 cm4

Layer 3; dy3 = h / 2 + rl × cos[(3 – 1) × a + a/2] = 74.9 mm

2nd moment of area of reinft about y axis; Iy3 = 2 × Abar × (dy3 – h/2)2 = 1537 cm4

Total 2nd moment of area of reinft about y axis; Isy = 3075 cm4

Radius of gyration of reinft about y axis; isy = √(Isy / As) = 102 mm

Effective depth about y axis (5.8.8.3(2)); dy = h / 2 + isy = 302 mm

Effective depth of bars for bending about z axis

Layer 1 (tension face); dz1 = h / 2 + rl = 344.5 mm

2nd moment of area of reinft about z axis; Iz1 = Abar × (dz1 – h / 2)2 = 1025 cm4

Layer 2; dz2 = h / 2 + rl × cos[(2 – 1) × a] = 272.3 mm

2nd moment of area of reinft about z axis; Iz2 = 2 × Abar × (dz2 – h/2)2 = 512 cm4

Layer 3; dz3 = h / 2 + rl × cos[(3 – 1) × a] = 127.8 mm

2nd moment of area of reinft about z axis; Iz3 = 2 × Abar × (dz3 – h/2)2 = 512 cm4

Layer 4; dz4 = h / 2 + rl × cos[(4 – 1) × a] = 55.5 mm

2nd moment of area of reinft about z axis; Iz4 = 1 × Abar × (dz4 – h/2)2 = 1025 cm4

Total 2nd moment of area of reinft about z axis; Isz = 3075 cm4

Radius of gyration of reinforcement about z axis; isz = √(Isz / As) = 102 mm

Effective depth about z axis (5.8.8.3(2)); dz = b / 2 + isz = 302 mm

Relative flexibility at end 1 for buckling about y axis

Second moment of area of column; Iy = π × h4 / 64 = 125664 cm4

Second moment of area of beam on side A; IA1y = bA1y × hA1y3 / 12 = 312500 cm4

Second moment of area of beam on side B; IB1y = bB1y × hB1y3 / 12 = 312500 cm4

Relative flexibility (PD6687 cl. 2.10); k1y = max(0.1, (Ecm × Iy / ly) / [2 × Ecm_b × (IA1y/lA1y + IB1y/lB1y)]) = 0.103

Relative flexibility end 2 for buckling about y axis; k2y = 1000.000

Relative flexibility at end 1 for buckling about z axis

Second moment of area of column; Iz = π × h4 / 64 = 125664 cm4

Second moment of area of beam on side A; IA1z = bA1z × hA1z3 / 12 = 312500 cm4

Second moment of area of beam on side B; IB1z = bB1z × hB1z3 / 12 = 312500 cm4

Relative flexibility (PD6687 cl. 2.10); k1z = max(0.1, (Ecm × Iz / lz) / [2 × Ecm_b × (IA1z/lA1z + IB1z/lB1z)]) = 0.100

Relative flexibility end 2 for buckling about z axis; k2z = 1000.000

Calculated effective length (cl. 5.8.3.2)

Eff. length about y axis (braced) (5.8.3.2(3));

l0y = 0.5 × ly × [(1 + k1y/(0.45+k1y)) × (1 + k2y/(0.45+k2y))]0.5 = 3851 mm

Eff. length about z axis (braced) (5.8.3.2(3));

l0z = 0.5 × lz × [(1 + k1z/(0.45+k1z)) × (1 + k2z/(0.45+k2z))]0.5 = 3843 mm

Column slenderness about y axis

Radius of gyration; iy = h / 4 = 10.0 cm

Slenderness ratio (5.8.3.2(1)); ly = l0y / iy = 38.5

Column slenderness about z axis

Radius of gyration; iz = h / 4 = 10.0 cm

Slenderness ratio (5.8.3.2(1)); lz = l0z / iz = 38.4

Design bending moments

Frame analysis moments about y axis combined with moments due to imperfections (cl. 5.2 & 6.1(4))

Ecc. due to geometric imperfections (y axis); eiy = l0y /400 = 9.6 mm

Min end moment about y axis; M01y = min(abs(Mtopy), abs(Mbtmy)) + eiy × NEd = 46.4 kNm

Max end moment about y axis; M02y = max(abs(Mtopy), abs(Mbtmy)) + eiy × NEd = 80.4 kNm

Slenderness limit for buckling about y axis (cl. 5.8.3.1)

Factor A; A = 0.7

Mechanical reinforcement ratio; w = As × fyd / (Ac × fcd) = 0.719

Factor B; B = √(1 + 2 × w) = 1.562

Moment ratio; rmy = M01y / M02y = 0.577

Factor C; Cy = 1.7 – rmy = 1.123

Relative normal force; n = NEd / (Ac × fcd) = 0.843

Slenderness limit; llimy = 20 × A × B × Cy / √(n) = 26.7

ly > llimy – Therefore, second order effects must be considered

Frame analysis moments about z axis combined with moments due to imperfections (cl. 5.2 & 6.1(4))

Ecc. due to geometric imperfections (z axis); eiz = l0z /400 = 9.6 mm

Min end moment about z axis;

M01z = min(abs(Mtopz), abs(Mbtmz)) + eiz × NEd = 19.9 kNm

Max end moment about z axis;

M02z = max(abs(Mtopz), abs(Mbtmz)) + eiz × NEd = 39.4 kNm

Slenderness limit for buckling about y axis (cl. 5.8.3.1)

Factor A; A = 0.7

Mechanical reinforcement ratio; w = As × fyd / (Ac × fcd) = 0.719

Factor B; B = √(1 + 2 × w) = 1.562

Moment ratio; rmz = M01z / M02z = 0.505

Factor C; Cz = 1.7 – rmz = 1.195

Relative normal force; n = NEd / (Ac × fcd) = 0.843

Slenderness limit; llimz = 20 × A × B × Cz / √(n) = 28.5

lz > llimz – Second order effects must be considered

Local second order bending moment about y axis (cl. 5.8.8.2 & 5.8.8.3)

Relative humidity of ambient environment; RH = 50 %

Column perimeter in contact with atmosphere; u = 1257 mm

Age of concrete at loading; t0 = 28 day

Parameter nu; nu = 1 + w = 1.719

Approx value of n at max moment of resistance; nbal = 0.4

Axial load correction factor; Kr = min(1.0 , (nu – n) / (nu – nbal)) = 0.665

Reinforcement design strain; eyd = fyd / Es = 0.00217

Basic curvature; curvebasic_y = eyd / (0.45 × dy) = 0.0000160 mm-1

Notional size of column; h0 = 2 × Ac / u = 200 mm

Relative humidity factor (Annex B.1(1)); φRH = 1 + [(1 – RH / 100%) / (0.1 mm-1/3 × (h0)1/3)] = 1.855

Concrete strength factor (Annex B.1(1)); βfcm = 16.8 × (1 MPa)1/2 / √(fcm) = 2.925

Concrete age factor (Annex B.1(1)); bt0 = 1 / (0.1 + (t0 / 1 day)0.2) = 0.488

Notional creep coefficient (Annex B.1(1)); φ0 = φRH × βfcm × βt0 = 2.650

Final creep development factor; (at t = ∞); βc∞ = 1.0

Final creep coefficient (Annex B.1(1)); fφ∞ = φ0 × βc∞ = 2.650

Ratio of SLS to ULS moments; rMy = 0.80

Effective creep ratio; φefy = φ∞ × rMy = 2.120

Factor b; by = 0.35 + fc /200 – λy/150 = 0.218

Creep factor; Kfy = max(1.0 , 1 + by × φefy) = 1.463

Modified curvature; curvemod_y = Kr × Kfy × curvebasic_y = 0.0000155 mm-1

Curvature distribution factor; c = 10

Deflection; e2y = curvemod_y × l0y2 / c = 23.0 mm

Nominal 2nd order moment;M2y = NEd × e2y = 34.6 kNm

Design bending moment about y axis (cl. 5.8.8.2 & 6.1(4))

Equivalent moment from frame analysis;

M0ey = max(0.6 × M02y + 0.4 × M01y, 0.4 × M02y) = 66.8 kNm

Design moment;

MEdy = max(M02y, M0ey + M2y, M01y + 0.5×M2y, NEd × max(h/30, 20 mm))

MEdy = 101.4 kNm

Local second order bending moment about z axis (cl. 5.8.8.2 & 5.8.8.3)

Basic curvature; curvebasic_z = eyd / (0.45 × dz) = 0.0000160 mm-1

Ratio of SLS to ULS moments; rMz = 0.80

Effective creep ratio (5.8.4(2)); φefz = φ∞ × rMz = 2.120

Factor b; bz = 0.35 + fck / 200 MPa – lz / 150 = 0.219

Creep factor; Kfz = max(1.0 , 1 + bz × fefz) = 1.464

Modified curvature; curvemod_z = Kr × Kfz × curvebasic_z = 0.0000156 mm–

Curvature distribution factor; c = 10

Deflection; e2z = curvemod_z × l0z2 / c = 23.0 mm

Nominal 2nd order moment; M2z = NEd × e2z = 34.5 kNm

Design bending moment about z axis (cl. 5.8.8.2 & 6.1(4))

Equivalent moment from frame analysis;

M0ez = max(0.6 × M02z + 0.4 × M01z, 0.4 × M02z) = 31.6 kNm

Design moment;

MEdz = max(M02z, M0ez + M2z, M01z + 0.5×M2z, NEd × max(b/30, 20 mm))

MEdz = 66.1 kNm

Resultant design bending moment for a circular column

Resultant design moment; MEd = √(MEdy2 + MEdz2) = 121.0 kNm

Moment capacity about y axis with axial load NEd

Moment of resistance of concrete

By iteration:-

Position of neutral axis; y = 289.8 mm

Depth of stress block; dsby = min(lsb × y , h) = 231.8 mm

Area of concrete in compression; Asby = 75498 mm2

Concrete compression force (3.1.7(3));Fyc = h × fcd × Asby = 962.6 kN

Centroid of concrete compression from column cl; ysby = 68.0 mm

Moment of resistance; MRdyc = Fyc × ysby = 65.4 kNm

Moment of resistance of reinforcement

Strain in layer 1; εy1 = εcu3 × (1 – dy1 / y) = -0.00043

Stress in layer 1; σy1 = max(-1×fyd, Es × εy1) = -85.5 N/mm2

Force in layer 1;Fy1 = 2 × Abar × sy1 = -83.9 kN

MRdy1 = Fy1 × (h / 2 – dy1) = 10.5 kNm

Strain in layer 2; εy2 = εcu3 × (1 – dy2 / y) = 0.00108

Stress in layer 2; σy2 = min(fyd, Es × εy2) – h × fcd = 204.1 N/mm2

Force in layer 2; Fy2 = 2 × Abar × sy2 = 200.4 kN

Moment of resistance of layer 2; MRdy2 = Fy2 × (h/2 – dy2) = 0.0 kNm

Strain in layer 3; εy3 = εcu3 × (1 – dy3 / y) = 0.00260

Stress in layer 3; σy3 = min(fyd, Es × εy3) – h × fcd = 422.0 N/mm2

Force in layer 3; Fy3 = 2 × Abar × sy3 = 414.3 kN

Moment of resistance of layer 3; MRdy3 = Fy3 × (h/2 – dy3) = 51.8 kNm

Resultant concrete/steel force; Fy = 1493.3 kN

PASS – This is within half of one percent of the applied axial load

Combined moment of resistance

Moment of resistance about y axis; MRdy = 127.8 kNm

Moment capacity about z axis with axial load NEd

Moment of resistance of concrete

By iteration:-

Position of neutral axis; z = 287.0 mm

Depth of stress block; dsbz = min(lsb × z , h) = 229.6 mm

Area of concrete in compression; Asbz = 74628 mm2

Concrete compression force (3.1.7(3)); Fzc = h × fcd × Asbz = 951.5 kN

Centroid of concrete compression from column cl; ysbz = 69.1 mm

Moment of resistance; MRdzc = Fzc × ysbz = 65.8 kNm

Moment of resistance of reinforcement

Strain in layer 1; εz1 = εcu3 × (1 – dz1 / z) = -0.00070

Stress in layer 1; σz1 = max(-1×fyd, Es × εz1) = -140.2 N/mm2

Force in layer 1; Fz1 = 1 × Abar × sz1 = -68.8 kN

Moment of resistance of layer 1; MRdz1 = Fz1 × (h / 2 – dz1) = 9.9 kNm

Strain in layer 2; εz2 = εcu3 × (1 – dz2 / z) = 0.00018

Stress in layer 2; σz2 = min(fyd, Es × εz2) = 36.0 N/mm2

Force in layer 2; Fz2 = 2 × Abar × sz2 = 35.3 kN

Moment of resistance of layer 2; MRdz2 = Fz2 × (h / 2 – dz2) = -2.6 kNm

Strain in layer 3; εz3 = εcu3 × (1 – dz3 / z) = 0.00194

Stress in layer 3; σz3 = min(fyd, Es × εz3) – h × fcd = 375.7 N/mm2

Force in layer 3; Fz3 = 2 × Abar × sz3 = 368.8 kN

Moment of resistance of layer 3; MRdz3 = Fz3 × (h/2 – dz3) = 26.6 kNm

Strain in layer 4; εz4 = εcu3 × (1 – dz4/z) = 0.00282

Stress in layer 4; σz4 = min(fyd, Es × εz4) – h × fcd = 422.0 N/mm2

Force in layer 4; Fz4 = 1 × Abar × sz4 = 207.2 kN

Moment of resistance of layer 4; MRdz4 = Fz4 × (h/2 – dz4) = 29.9 kNm

Resultant concrete/steel force; Fz = 1494.0 kN

PASS – This is within half of one percent of the applied axial load

Combined moment of resistance

Moment of resistance about z axis; MRdz = 129.8 kNm

Minimum moment capacity with axial load NEd

Minimum moment capacity; MRd = min(MRdz, MRdy) = 127.8 kNm

PASS – The moment capacity exceeds the resultant design bending moment

Summary

| Description | Unit | Provided | Required | Utilisation | Result |

| Moment capacity (y) | kNm | 127.79 | 101.41 | 0.79 | PASS |

| Moment capacity (z) | kNm | 129.76 | 66.06 | 0.51 | PASS |

| Combined capacity | kNm | 127.79 | 121.03 | 0.95 | PASS |

Jacketing concrete pad,column,beam,slab in construction