Haunches are usually provided at the eaves of rigid portal frames due to a lot of beneficial reasons. They are usually cut from the same section as the rafter, or can be fabricated by welding different plates together. After fabrication, they are welded to the underside of the rafter at the eaves. Knowing that maximum bending moment occurs at the eaves of portal frames, haunches play the major function of increasing the bending resistance of the rafter.

Read Also…

Structural analysis of portal frames subjected to gravity load

Preliminary plastic analysis of portal frames

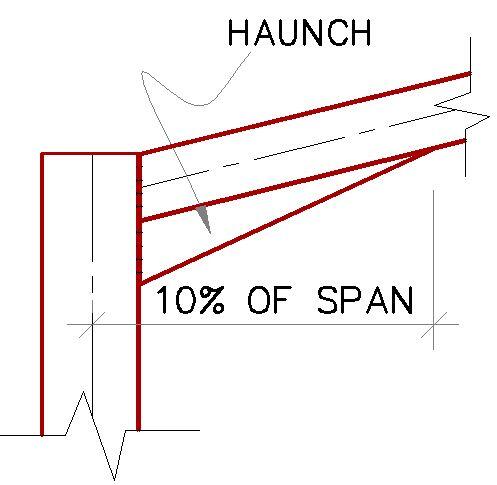

A portal frame is a continuous frame with moment-resisting connections. If the connection between the column and the rafter is not rigid, the frame will be unstable in-plane. The continuous nature of the frame provides in-plane stability, and resistance to lateral loads such as wind load. As a result, the stability of the frame and its resistance to deformation depends on the stiffness of the columns and rafters, which are the primary members of the frame. Hot rolled steel sections are normally used as the primary members, with the resistance of the rafters enhanced locally by a haunch at the eaves, where the bending moments are greatest. Usually, the frame is assumed to have nominally pinned bases, even if the actual base details possess appreciable stiffness. The main frames are generally fabricated from UKB sections. The eaves haunch is created by adding a tapered length cut from a rolled section, or fabricated from plate.

Read Also …

Design of bolted beam splice connections to Eurocode 3

Design of roof purlins

Consequently, haunches enhance the economical design of rafters of portal frames, by reducing the depth of the section required. Haunches also assist in the reduction of deflection and facilitate efficient rigid bolted connection between the rafter and the column. The typical length of the eaves haunch is generally 10% of the frame span. When this is done, the value of the hogging moment at the end of the haunch will be approximately equal to the sagging moment in the rafter, which can lead to a better design of the portal frame. Note that the depth of haunch below the rafter is approximately equal to the depth of the rafter section.

The apex haunch may be cut from a rolled section – often from the same size as the rafter, or fabricated from plate. This member is not usually modelled in the frame analysis and is not needed to enhance the bending resistance; it is only used to facilitate a bolted connection.

„This member is not usually modelled in frame analysis and is not needed…” did you ever heard about 3D structure optimisation ???