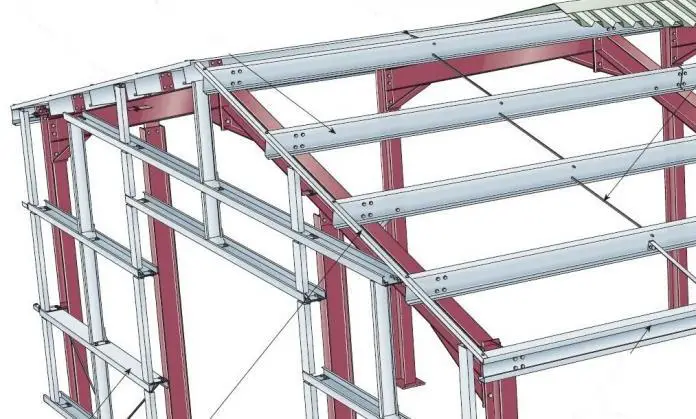

Roof purlins are members used to directly support roof sheeting materials, and could be made of timber or steel. In timber construction, purlins are nailed to the rafter or supporting trusses, while in steel roof construction, they are welded or bolted to the rafters or trusses by the means of cleats. As structural members, they resist loads, and provide lateral restraints for truss members, therefore it is important to design them properly against forces such as bending, shear, torsion, buckling etc.

In their design life, purlins are subjected to dead load (e.g self weight of sheeting materials and accessories), live load (e.g. during maintenance services and repairs), and environmental loads (e.g. wind and snow load). Therefore, a purlin should be adequately strong to withstand the loads it will encounter during its design life, and should not sag in an obvious manner thereby giving the roof sheeting an undulating and/or unpleasant appearance. This article will be focusing on design of steel purlin using cold formed sections.

Arrangement of Roof Purlins

By default, purlin sections assume the slope of the roof they are supporting. The spacing of roof purlins on rafters usually calls for careful arrangement, in the sense that it should follow the nodal pattern of the supporting trusses. By implication, purlins should ideally be placed at the nodes of trusses and not on the members themselves so as not to induce secondary bending and shear forces in the members of the truss. Furthermore, if manual analysis is employed to analyse a truss loaded in such a manner, such secondary stresses may not be captured especially if nominally pinned connections are assumed.

Cold formed Z (Zed) and C (channel) sections are normally specified for roof purlins in steel structures (see their form in image below).

When compared with thicker hot-rolled sections, cold-formed sections normally offer the advantages of lightness, high strength and stiffness, easy fabrication and installations, easy packaging and transportation etc. The connection of purlins can be sleeved or butted depending on the construction method adopted.

In terms of arrangement of roof purlins, we can have single spans with staggered sleeved/butt arrangement, single/double span with staggered sleeve arrangement, double span butt joint system, and single span butt joint system. The choice of the arrangement to be adopted can depend on the supply length of the sections as readily available in the market, the need to avoid wasteful offcuts, the loading and span of the roof, the arrangement of the rafters etc.

Therefore the roof designer must plan from start to finish. However, single and double span butt joint system are the most popular in Nigeria, due to their simplicity, and the culture of adopting shorter roof spans in the country. However, they are less structurally efficient than sleeved connections.

Design Example of Roof Purlins

We are to provide a suitable cold formed channel section for the purlin of the roof arrangement shown below.

Partial Factor for loads (BS EN 1990 NA 2.2.3.2 Table NA.A1.2(B))

Permanent action γG = 1.35 (unfavourable)

Variable action γG = 1.5

Combination factor for Roofs, ψ0 = 0.7

Wind loads, ψ0 = 0.5

Reduction factor ξ = 0.925

Initial Sizing of Sections

The maximum spacing of the trusses is at 3000 mm c/c

Limiting the deflection to L/200;

For continuous purlins, minimum depth of section (preliminary guide) = L/45

3000/45 = 66.667

Minimum width = 0.5L/60 = (3000/2)/60 = 25

Try C120-15 section (C – purlin) (Section picked from Albion Technical Manual, 2010).

Section Properties

In the design of purlins using EN 1993-1-3:2006, we normally utilise the effective section properties. This calculation of effective section properties can be very tedious and prone to error, hence it is very advisable to obtain information from the manufacturer’s details or you can write a program using Microsoft Excel or MATLAB for such calculations. However, we are going to make a sample calculation for the section that we are considering.

Thickness (tnom) = 1.5 mm

Depth = 120mm;

Flange width = 50 mm;

Lips/Edge Fold = 15 mm;

Steel core thickness (t) = 1.5 – 0.05 = 1.45 mm (Note that EN 1993-1-3:2006 recommends a thickness of 0.04 mm for zinc coated sections, but we are using 0.05 mm here)

Unit weight = 2.8 kg/m2;

Web height hp = h – tnom = 120 – 1.5 = 118.5 mm

Width of flange in tension = Width of flange in compression bp1 = bp2 = b – tnom = 50 – 1.5 = 48.5 mm

Width of edge fold cp = C – tnom/2 = 15 – 1.5/2 = 14.25 mm

Checking of geometrical proportions

b/t ≤ 60 b1/t = 48.5/1.45 = 33.448 < 60 – OK

c/t ≤ 50 c/t = 15/1.45 = 10.344 < 50 – OK

h/t ≤ 500 c/t = 120/1.45 = 82.758 < 500 – OK

0.2 ≤ c/b ≤ 0.6 c/b1 = 15/48.5 = 0.309 – OK

The effect of rounding corners due to root radius has been neglected in this design.

Gross section properties

Abr = t(2cp + bp1 + bp2 + hp) = 1.45[(2 × 14.25) + 48.5 + 48.5 + 118.5)] = 353.8 mm2

Position of the neutral axis with respect to the flange in compression;

Zb1 = 1.45[14.25(118.5 – 7.125) + (48.5 × 118.5) + 118.52/2 + 14.252/2] / 353.8 = 59.253mm

Effective section properties of the flange and lip in compression (clause 3.7.2)

Effective width of the compressed flange;

The stress ratio ψ = 1.0 (uniform compression)

kσ = 4 for internal compression element (clause 3.7.2 Table 3.5)

ε = √(235/fyb) = √(235/350) = 0.819

The effective width is;

beff = ρbb1 = 0.966 × 48.5 = 46.851 mm

be1 = be2 = 0.5beff = 0.5 × 46.851 = 23.4255 mm

Effective Width of the edge fold (lip) Clause 3.7.3.2.2 Equation 3.47

The buckling factor is;

cp ⁄ bp1 = 14.25/48.5 = 0.2938 < 0.35

So kσ = 0.5

Therefore since 1.149 < 1.0, take reduction factor as 1.0

The effective width is therefore ceff = ρcp = 1.0 × 14.25 = 14.25mm

The effective area of the edge stiffener;

As = t(be2 + ceff) = 1.45 (23.4255 + 14.25) = 54.629 mm2

We now have to use the initial effective cross-section of the stiffener to determine the reduction factor, allowing for the effects of the continuous spring restraint.

The elastic critical buckling stress for the edge stiffener is;

Where K is the spring stiffness per unit length;

b1 is the distance of the web to the centre of the effective area of the stiffener in compression flange (upper flange);

kf = 0 for bending about the y-y axis

Therefore;

= 175882.211 × 0.00000491305 = 0.8641 N/mm

So the elastic critical buckling stress for the edge stiffener is;

σcr,s = (2√(0.8641 × 210000 × 1007.801))/(54.629 ) = 495.901 N/mm2

The relative slenderness factor for the edge stiffener;

In our own case;

χd = 1.47 – 0.723(0.840)= 0.862

As the reduction factor for buckling is less than 1.0, we can optionally iterate to refine the value of the reduction factor for buckling of the stiffeners according to clause 5.5.3.2(3). But we are not iterating in this post.

Therefore;

χd = 0.862

be2 = 23.4255 mm

ceff = 14.25mm

The buckling factor kσ = 7.81 – 6.29ψ + 9.78ψ2

kσ = 7.81 – 6.29(-0.9346) + 9.78(-0.9346)2 = 22.231

Therefore, take ρ as 1.0 since 1.137 > 1.0.

Therefore, the effective width of the zone in compression of the web is;

heff = ρhc = 1.0 × 61.252 = 61.252mm

Near the flange in compression;

he1 = 0.4heff = 0.4(61.252) = 24.5mm

he2 = 0.6heff = 0.6(61.252) = 36.7512mm

The effective width of the web is;

Near the flange in compression;

h1 = he2 = 24.5mm

Near the flange in tension;

h2 = hp – (hc – he2) = 118.5 – (61.252 – 36.7512) = 93.992mm

Effective section properties;

Aeff = 1.45 × [14.25 + 48.5 + 24.5 + 93.992 + 23.4255 + (23.4255 + 14.25) 0.862]

Aeff = 343.858 mm2

Position of the neutral axis with regard to the flange in compression;

zc = 1.45[(14.25 × 111.375) + (48.5 × 118.5) + (93.992 × 71.504) + 300.125 + 87.5199] / 343.858 = 60.903 mm

Position of the neutral axis with regard to the flange in tension;

Zt = hp – Zc

Second moment of area:

Effective section modulus;

With regard to the flange in compression;

Weff,y,c = Ieff,y/zc = (777557.517) / 60.903 = 12767 mm3

With regard to the flange in tension;

Weff,y,t = Ieff,y/zt = (777557.517) / 57.697 = 13476 mm3

LOAD ANALYSIS

Permanent loads

Employing long span aluminium roofing sheet (gauge thickness = 0.55mm)

Load due to sheeting = 0.019 kN/m2

Other permanent accessories and fittings = 0.15 kN/m2

Total = 0.169 kN/m2

At a spacing of 1.2m, = 0.169 kN/m2 × 1.2m = 0.2028 kN/m

Self weight of purlin = 2.8 kg/m = 0.0275 kN/m

Total Gk = 0.2028 KN/m + 0.0275 KN/m = 0.230 kN/m

Live load

For a roof with 20° slope and no access except for normal repairs and maintenance, let us adopt a live load of 0.75 kN/m2

At a spacing of 1.2m, Qk = 0.75 kN/m2 × 1.2m = 0.9 kN/m

Wind Load

Taking a dynamic wind pressure of 1.5 kN/m2

When the wind is blowing from right to left, the resultant pressure coefficient on a windward slope with positive internal pressure is;

cpe = −0.90 upwards

Therefore the external wind pressure normal to the roof is;

pe = qpcpe = 1.5 × − 0.90 = −1.35 kN/m2

The vertical component of the wind pressure is;

pev = pecosθ = −1.35 × cos 20° = −1.268 kN/m2 acting upwards.

At a spacing of 1.2m;

Wk = −1.268 kN/m2 × 1.2m = 1.522 kN/m

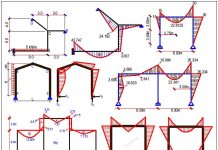

STATIC SYSTEMS

We are adopting two possible systems that will offer us continuous and single span systems. The 6m span is based on supply length.

Static Model 1

Static Model 2

Load Case 1

When Dead load and live load are acting alone;

q = 1.35Gk + 1.5Qk = 1.35(0.230) + 1.5(0.9) = 1.6605 kN/m

Model 1

Load Case 2

When Dead load, live load and wind load are acting together;

q = 1.35Gk + 1.5Qk + 0.9Wk

Where the live load is the leading variable action

q = 1.35(0.230) + 1.5(0.9) – 0.9 (1.522) = 0.2907 kN/m

Model 1

Model 2

Load Case 3

When Dead load and wind load are acting alone;

q = 1.0Gk – 1.5Wk

Where dead load is favourable

q = 1.0(0.230) – 1.5(1.522) = -2.053 kN/m

Model 1

Model 2

Maximum span design moment MEd = 2.31 kNm

Maximum shear force VEd = 3.85 kN

Verification of Bending

Design moment resistance

MC,Rd = Weff,y.Fy / γm0 [Clause 6.1.4.1(1) of EN 1993-1-3:2006]

From our calculations;

Weff,y = min(Weff,y,c , Weff,y,t) = 12767 mm3

Therefore;

MC,Rd = Weff,y.Fy/γm0 = [(12767 mm3) × (350) × 10-6] / 1.0 = 4.46845 KNm

Check of span and single support;

MEd/MC,Rd = 2.31/4.46845 = 0.5169 < 1.0 OK!

Check of shear resistance at ULS

The design shear resistance is given by;

Vb,Rd = (hw/sinφ.t.fbv) / γM0 (Clause 6.1.5)

The shear buckling strength (fbv) which is based on the relative web slenderness can be obtained from the table below (Table 6.1 of EN 1993-1-3).

Where λw ̅ is the relative slenderness for webs without longitudinal stiffeners.

Since 1.154 < 0.83 but less than 1.40;

fbv = 0.48fyb = 0.48 × 350 = 168 N/mm2

Vb,Rd = [(118.5 / sin90°) × 1.45 × 168] / 1.0 = 28866.6 N = 28.867 KN

Check for shear (using maximum shear force);

VEd / Vb,Rd = (3.85)/(28.867) = 0.1333 < 1.0 Shear is ok

Deflection Check

Maximum deflection under SLS (1.0gk + 1.0qk) = 0.07 mm

Limiting deflection = L/200 = 3000/200 = 15 mm

Since 0.07 < 15mm, deflection is Ok!

Therefore, the channel Z120-15 section is adequate for the applied load.

am so happy knowing you and this site, you r jst an evidence dat young engineers can it very well. your passion and drive is something dat has no match. i ve such almost similar passion too but forces around are some worth tough but since knowing dis site, am born-again, lolz. big ups brother, God will bless u outrageously for d knowledge u r sharing wit ur fellow engineers.

I am elated to hear this. Let us remain dedicated to the right cause. God bless you.

Ubani this is a good platform for the engineers especially the new generation. Keep it up.This gives me a lot of additional knowledge

Thank you Wes

I have been following your blog, graduated last year and currently serving our country in Calabar, cross River State. The best thing that has happened to me towards the end of last year(2017) is joining Apele whatsaap group knowing you and this educational site.

God will continue to bless you and strength you in your dreams.

Much love from me to you sir.

Best regards,

Iduh obiajulu Severious

This is the reason it is a smart thought to dependably have no less than one encountered roofer helping when you introduce a roof.

The first thing you need to consider is the experience of a professional, is the best for their work.

There are an assortment of reasons why you ought to have your rooftop reestablished. Rooftop Restoration isn't just enhances the quality and life span of your rooftop, it additionally expands the estimation of your home and enhance appearance.

As said, even the most cautious property holder should have repairs done on their rooftop now and again.

The rooftop characterizes the working in every perspective and in addition its magnificence. It gives the occupants the securities that they requirement for a wide range of climate condition.

Talking about inclines, there are prerequisites that must be considered and just a roofer comprehends these.

Ladders

• Somebody necessarily lend a hand to make significantly articles I’d state. That is the very first time I frequented your website page and to this point? I amazed with the research you made to make this particular submit amazing. Excellent job!

Much thanks to you for setting aside an ideal opportunity to distribute this data extremely valuable! Roofing Lilburn

Pitched roofs are the most common types of roofs. The pitch of the roof is a measurement of how steep the roof is which determines how quickly the water will run off of the roof.Roofing Contractors Sudbury

Most single family home will not have a green roof in most neighborhoods but if your home is in an environment that supports this type of roof then by all means go for it.

very informative work, learning steel design is very essential in these days.

Can you please show the formulas and values used to calculate each of the graphs? The calculated values for static model 1 graphs in each load case appear to work using a 3m span length on a two span continuous beam. The displayed values in the second model (simply supported 6m span) graphs appear to be using 3m rather than 6m. eg for bending moment max in model 2, load case 1 using wL^2/8, I get a result of 1.6605 x 6m x 6m / 8 which gives 7.472kN. I’m confused are the model 2 graph values correct or have I made a mistake?