Underpinning is a process used to rectify distress caused to a building by excessive movement of its foundation, to extend foundations into the ground to facilitate future construction work, to accommodate additional load applied to an existing building, to allow the adjacent ground to be lowered, or to change the support system (BS 8004-2015).

According to BS 8004-1986, the two major objectives of underpinning are to transfer the load carried on a foundation from its existing bearing level to a new level at a lower depth and to limit the settlement of foundations.

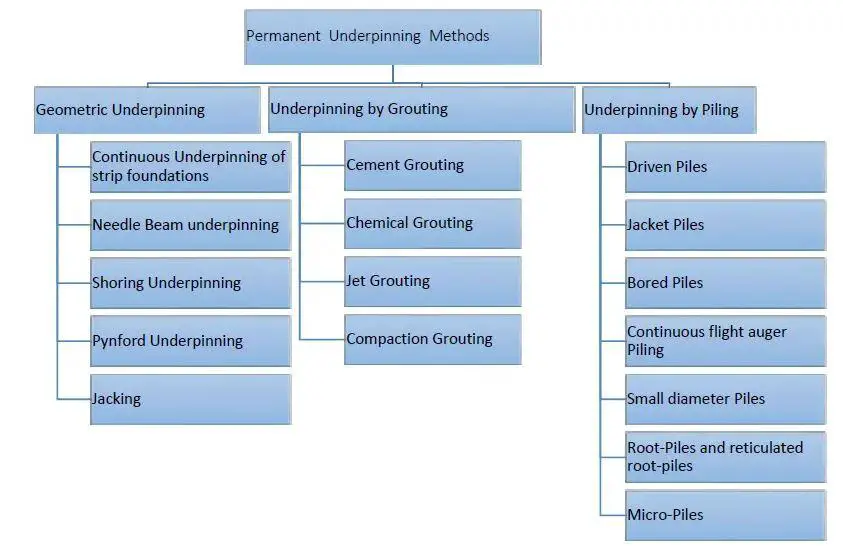

Types of Underpinning

According to BS 8004, the major types of underpinning include:

- Extending the depth of strip or pad footings (continuous underpinning constructed in sections usually not exceeding 1.2 m);

- Constructing piles that are drilled through the foundations;

- Constructing ground beams beneath walls formed by stooling or needling and supported by piers or piles;

- Constructing ground beams beside walls supported by piers or piles with needles and/or load transfer by stressing or other details to transfer the load to the new support.

Generically, the types of permanent underpinning can be seen in the chart below;

Before underpinning is considered and resorted to, it is very important for an experienced and competent person to carry out a full investigation to determine whether the purpose of carrying out the underpinning will be achieved. The choice of underpinning system is expected to consider the loads carried, the sensitivity of the ground and the existing structure, nearby structures, and the working conditions.

The ground investigation should determine the conditions responsible for any excessive movement so that appropriate underpinning measures will be taken. Furthermore, the general nature of the ground, load-bearing capacity, and the effects of adjoining foundations should be determined before the full design of the underpinning system can be done.

Furthermore, the structure to be underpinned should be carefully investigated. All indications of distress, differential foundation settlement, and weak planes which may be accentuated during the process of underpinning should be identified and temporarily supported and/or strengthened before the underpinning can commence.

Design for Underpinning

Underpinning systems should be designed in accordance with good soil mechanics practice taking into account all vertical and lateral loads imposed upon them, including particularly transient conditions that may arise during construction. The design of underpinning should be done according to EN 1997-1 and Clause 4 of BS 5400:2015. The structural design of underpinning for spread and pile foundations should conform to relevant standards.

It is important to note that underpinning may alter or deepen only part of a foundation if only part is to be underpinned or is shown to be unstable. The designer has to be satisfied that the whole foundation including that part modified by underpinning will continue to perform satisfactorily.

If the changed support conditions will inevitably give rise to excessive differential movement, jacks may be installed temporarily or permanently to correct this. Such elaborate arrangements are rarely required except when underpinning particularly heavy walls or piers. If the whole of a structure is subsiding unevenly, for example, a building on a bed of made-up ground of variable thickness, partial underpinning will be unsuccessful and the whole structure has to be underpinned.

Construction Processes for Underpinning

Live Load Reduction

Before the commencement of excavation, it is important to reduce the live loads on the walls and columns of the structure as practically as possible. This is more important when the live load is large in relation to the dead load.

Excavation

The area of open excavations should not exceed 25% of the building’s footprint. This limit should be reduced if the building comprises a number of isolated piers.

Support of Excavations

All excavations necessary for underpinning should be properly supported using struts of steel, timber, concrete, or other adequate temporary or permanent works as adequately designed using standard geotechnical processes.

Underpinning legs

If the underpinning will not give rise to excessive ground pressure, the underpinning process should be carried out in a series of legs. The length of each leg should depend on the general character and condition of the ground and the structure to be underpinned, the intensity of the loading, and the nature of the ground below. In normal brick or stone walls, each leg should be 1000 mm to 1400 mm in length. This length can be increased in walls that are capable of arching.

Each series of legs should be planned to provide sufficient support between the legs under construction and to ensure that the loads from the unsupported portions of the wall are distributed throughout the length of the wall.

If underpinning is required to take care of excessive settlement, or if the allowable settlement is likely to be exceeded during the underpinning operations, the structure to either side of an underpinning leg should be needled and the load transferred to temporary bearings capable of carrying the additional load. Alternatively, stooled reinforced concrete beam might be introduced before the underpinning can commence.

If the width of the foundation to be underpinned is greater than 1000 mm, it is advisable to leave the outer half more than 150mm below the underside of the foundation to facilitate the pinning up of the furthest part.

I appreciated it when you shared that it is important to conduct an investigation before an underpinning operation can be done. This will ensure that the issue can be resolved using the right operations. I would like to think if a homeowner has issues with his house foundation, he should consider working with a reliable underpinning service.

I like how you mentioned that underpinning can help with providing support for the foundation. My uncle mentioned to me last night that he starts seeing cracked floors in their home and asked if I have any idea what is the best option to do. Thanks to this informative article and I’ll be sure to tell him that it will be much better if we consult a trusted underpinning service as they can answer all our inquiries and figure out what type of service their home needs to keep them safe.

Is this still underpinning of weak stripe foundation