Columns are compression members used for transferring superstructure loads to the foundation. In reinforced concrete detailing and construction, the lapping of reinforcements is almost unavoidable due to logistics and handling issues during construction. As a result, design codes all over the world have guidelines on how to properly lap reinforcements in columns.

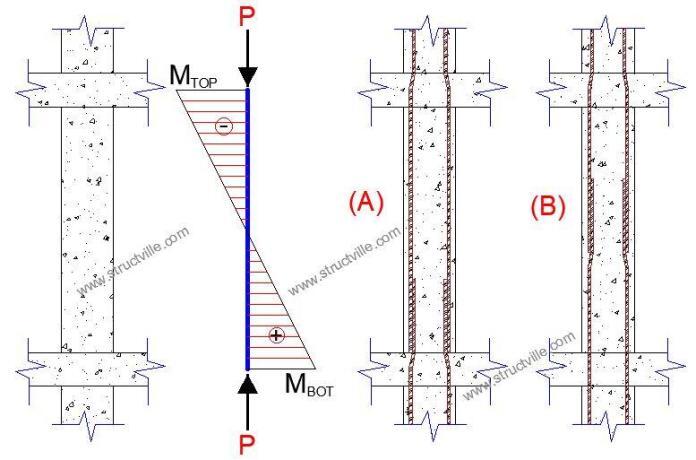

Improper detailing of reinforced concrete columns can lead to concrete spalling, cracking, and other forms of failure, which may compromise the structural integrity of a column. A poorly arranged reinforcement can also lead to premature buckling and bending that can reduce the load-carrying capacity of reinforced concrete columns.

Here are some important detailing guidelines provided for column laps;

(1) When the diameter of both bars at the lap exceeds 20mm and the cover is less than 1.5 times the size of the smaller bar, transverse links shall be provided throughout the lap length.

(2) At the lap, the least link diameter should be at least one-quarter the size of the smaller bar.

(3) Link spacing shall not exceed;

(a) 12 x diameter of the smallest bar

(b) 0.6 x dimension of the smallest side of the column

(c) 240 mm

(4) Compression lap length should be at least 25% greater than the compression anchorage length.

(4) For cranked bars, the minimum slope of the crank should be maintained at 1:10. However, this value may be increased up to 1:20 for smooth load transfer.

However, the code appears to be silent on the actual location where columns should be lapped. What do you think? Kindly comment below.

b

B