Arches are important structural elements in engineering that provide economical solutions in buildings and bridges. Three-hinged arch structures are pinned at the supports (springings) and somewhere along the barrel, which is usually at the crown. The structural analysis and design of three-hinged arches involve the determination of the internal stresses (bending moment, shear force, axial force, and torsion in the structure due to externally applied load, and providing adequate sections to resist the applied load.

In horizontal beams supporting uniformly distributed load, the bending moment increases with the square of the span and hence they become uneconomical for long-span structures. In such situations, arches could be advantageously employed, since they would develop horizontal reactions, which in turn reduce the bending moment.

A three-hinged arch, which is usually made from steel or timber, is statically determinate. Unlike statically indeterminate arches, they are not affected by differential settlement or temperature changes. Three-hinged arch structures have three natural hinges as the name implies. The two supports are hinged, and another internal hinge is usually located at the crown.

A three-hinged arch has four unknown reactions, i.e., two vertical reactions and two horizontal reactions at the supports. For their determination, three equilibrium equations can be formulated considering the whole of the structure.

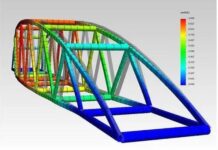

Since it is well known that the bending moment at any internal hinge is zero, the internal hinge in the barrel of the arch provides an additional equation for the equilibrium of any part of the system. This means that the sum of the moments of all external forces, which are located on the right (or on the left) part of the structure with respect to the internal hinge is zero. Therefore, a three-hinged arch is a geometrically unchangeable and statically determinate structure. The figure below shows a three-hinged Bolt-laminated Ekki Timber bridge at Finowfurt, Germany.

The peculiar feature of arched structures is that horizontal reactions are induced even when the structure is subjected to vertical load only. These horizontal reactions under vertical loading Ax = Bx = H are called the thrust of the structure. At any cross-section of the arch, bending moments, shear, and axial forces are developed. However, the bending moments and shear forces are smaller than corresponding internal forces in a simply supported beam covering the same span and subjected to the same load.

This fundamental property of the arch is thanks to the thrust developed. Thrusts in both supports are pointed towards each other and consequently reduce the bending moments that would arise in beams of the same span and load configuration. The two parts of an arch may be connected by a tie. In this case in order for the structure to remain statically determinate, one of the supports of the arch should be supported on a roller.

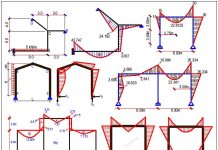

Solved Example on Analysis of a Three-hinged Arch

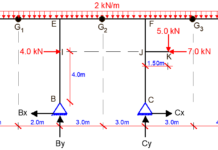

For the parabolic arch that is loaded as shown below, compute the support reactions and plot the internal stresses diagram for the identified sections. The arch is hinged at points A, B, and C.

SOLUTION

Geometrical properties of the arch

The ordinate (y) at any point along a parabolic arch is given by;

y = [4yc (Lx – x2)] / L2

Where;

yc = Height of the crown of the arch from the base

L = Length of arch

x = Horizontal ordinate of interest

Hence, y = [4 × 10 (45x – x2)] / 452

The general equation of the arch now becomes;

y = (8/9)x – (8/405)x2 —————– (1)

Differentiating equation (1) with respect to x

dy/dx = y’ = (8/9) – (16/405)x —————— (2)

From trigonometric relations, we can verify that;

Sin θ = y’/[1 + (y’)2]0.5 —————- (3)

Cos θ = 1/[1+ (y’)2]0.5 —————- (4)

From the above relations, we can carry out the calculations for obtaining the geometrical properties of the arch structure.

Let us consider point A (support A of the structure);

We can verify that at point A, x = 0, and y = 0;

From equation (2) above, y’ = 8/9;

Thus,

Sin θ = (8/9)/[1 + (8/9)2]0.5 = 0.664

Cos θ = 1/[1 + (8/9)2]0.5 = 0.747

Similarly, let us consider point 3 of the structure;

At point 3, x = 27.5m

From equation (1), we can obtain the value of y as; y = [(8/9) × 27.5] – [(8/405) × 27.52] = 9.5061m;

The tangent at that point can be obtained from from equation (2); dy/dx = y’ = (8/9) – [(16/405) × 27.5] = – 0.1975

Thus,

Sin θ = (-0.1975)/[1 + (-0.1975)20.5 = -0.1937

Cos θ = 1/[1 + (-0.1975)2]0.5 = 0.9813

For the entire section, it is more convenient to set out the geometrical properties in a tabular form. See the picture below;

Support Reactions

Let ∑MB = 0; anticlockwise negative

(Ay × 45) – (12 × 22.5 × 33.75) – (25 × 10) – (15 × 6.913) = 0

Therefore, Ay = 210.36 kN

Let ∑MA = 0; clockwise negative

(By × 45) – (25 × 35) + (15 × 6.913) – (12 × 22.5 × 11.25) = 0

Therefore, By = 84.64 kN

Let ∑MCL = 0; anticlockwise negative

(Ay × 22.5) – (Ax × 10) – (12 × 22.5 × 11.25) = 0

22.5Ay – 10Ax = 3037.5 ——— (a)

Substituting, Ay = 210.36 kN into equation (a)

Hence, Ax = 169.56 kN

Let ∑MCR = 0; clockwise negative

(By × 22.5) – (Bx × 10) – (25 × 12.5) – (15 × 3.087) = 0

22.5By – 10Bx = 358.8 ——— (b)

Substituting, By = 84.64 kN into equation (b)

Hence, Bx = 154.56 kN

Internal Stresses

Bending Moment

MA = 0 (hinged support)

M1 = (210.36 × 7.5) – (169.56 × 5.555) – (12 × 7.5 × 3.75) = 298.294 kN.m

M2 = (210.36 × 15) – (169.56 × 8.889) – (12 × 15 × 7.5) = 298.181 kN.m

MC = (210.36 × 22.5) – (169.56 × 10.000) – (12 × 22.5 × 11.25) = 0

Coming from the right hand side;

MC = (84.64 × 22.5) – (154.56 × 10) – (25 × 12.5) – (15 × 3.087) = 0

M3 = (84.64 × 17.5) – (154.56 × 9.506) – (25 × 7.5) – (15 × 2.593) = -214.442 kN.m

M4 = (84.64 × 10) – (154.56 × 6.913) = -222.073 kN.m

MB = 0 (hinged support)

Shear

Q = ∑V cosθ – ∑H sinθ

QA = (210.36 × 0.747) – (169.56 × 0.664) = 44.551 kN

Q1 = [210.36 – (12 × 7.5)] 0.860 – (169.56 × 0.509) = 17.203 kN

Q2 = [210.36 – (12 × 15)] 0.959 – (169.56 × 0.284) = -19.040 kN

QCR = [210.36 – (12 × 22.5)] 1.000 – (169.56 × 0.000) = – 59.64 kN

Q3 = [210.36 – (12 × 22.5)] 0.981 – (169.56 × – 0.193) = – 25.782 kN

Q4L = [210.36 – (12 × 22.5)] 0.897 – (169.56 × – 0.443) = – 21.618 kN

Q4R = {[210.36 – (12 × 22.5) – 25] × 0.897} – [(169.56 – 15) × (- 0.443)] = 7.452 kN

QB = (- 84.64 × 0.747) – [154.56 × (- 0.664)] = 39.402 kN

Axial

N = -∑V sinθ – ∑H cosθ

NA = (-210.36 × 0.664) – (169.56 × 0.747) = – 266.340 kN

N1 = – [210.36 – (12 × 7.5)] 0.509 – (169.56 × 0.860) = – 207.085 kN

N2 = – [210.36 – (12 × 15)] 0.284 – (169.56 × 0.959) = -171.230 kN

NC = – [210.36 – (12 × 22.5)] 0.000 – (169.56 × 1.000) = -169.560 kN

N3 = -{[210.36 – (12 × 22.5)] × – 0.193} – (169.56 × 0.981) = -177.849 kN

N4L = -{[210.36 – (12 × 22.5)] × – 0.443} – (169.56 × 0.897) = – 178.516 kN

N4R = -{[210.36 – (12 × 22.5) – 25] × – 0.443} – [(169.56 – 15) × (0.897)] = – 176.136 kN

NA = – (-84.64 × – 0.664) – (154.56 × 0.747) = – 171.657 kN

Internal Stresses Diagram (Not to scale)

Like us on www.facebook.com/structville

Thank you for visiting.

Nice one. Thanks for the info

Thank you Engr.