Precast concrete columns are reinforced concrete columns that are cast and cured on the ground before being hoisted up and installed in their desired positions. Just like in-situ columns, precast columns are capable of resisting shear, axial force, and bending moment, however, careful attention must be paid to their connection details. The design of precast concrete columns involves the provision of adequate member size, reinforcement, and connection details to satisfy internal stresses due to externally applied loads, second-order effects, and lifting.

Different connection conditions can be adopted by different manufacturers. The foundation connection of a precast column may be achieved by allowing reinforcement bars to project from the column which is then passed through established sleeves before being filled with concrete grout. Alternatively, a base plate can be connected to the column which is then installed in position on a concrete base using bolts and nuts.

Precast columns may have corbels or nibs for supporting the beams. Alternatively, precast beam-column connections can be made using dowels or mechanical couplers.

Precast concrete columns have the following advantages over in-situ concrete construction;

- Increased speed in construction since production of precast elements can commence ahead of time

- Greater flexibility in project management and site planning due to off-site production capacity

- Improved and higher quality of concrete, dimensions, and surface finishes

- Reduction in site labour

- Reduction in formwork requirement

- Less wastage of materials

The design of precast reinforced concrete columns is carried out by a structural engineer and involves the following steps;

- Confirm all dimensions and tolerances of the column and other members.

- Analyse the structure to obtain the design bending moments, axial, and shear force

- Check for column slenderness

- Obtain the final design moments taking into account imperfections and second-order effects (if applicable)

- Provide reinforcements to satisfy bending and axial force

- Check for biaxial bending

- Check for shear

- Check that reinforcement provided satisfies bending and shear due to factory lifting

- Check that reinforcement provided satisfies bending and shear due to site pitching

- Design the connections

- Detail the column as appropriate

Worked Example on the Design of Precast Columns | EN 1992-1:2004

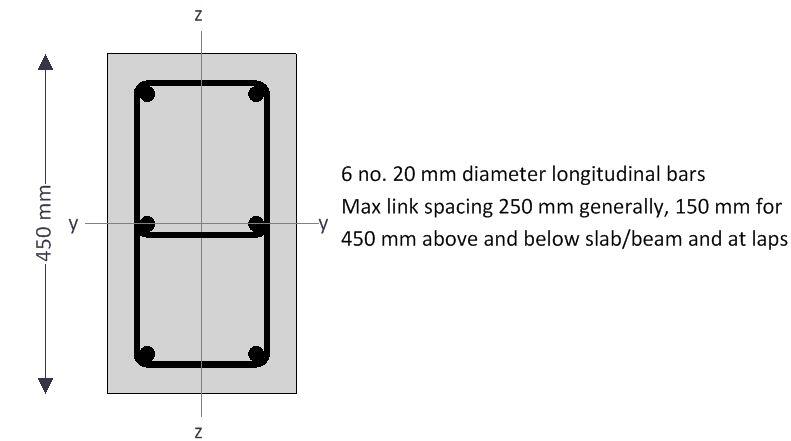

Check the capacity of a 4.5m high 450 x 250 mm precast column to resist the action effects given below. The column is reinforced with 6 numbers of H20 mm bars. fck = 35 N/mm2; fyk = 500 N/mm2; Concrete cover = 35 mm. The design has been executed using Tekla Tedds software.

Axial load and bending moments from frame analysis

Design axial load; NEd = 1350.0 kN

Moment about y-axis at top; Mtop,y = 55.0 kNm

Moment about y-axis at bottom; Mbtm,y = 22.0 kNm

Moment about z-axis at top; Mtop,z = 11.4 kNm

Moment about z-axis at bottom; Mbtm,z = 5.5 kNm

Column geometry

Overall depth (perpendicular to y-axis); h = 450 mm

Overall breadth (perpendicular to z-axis); b = 250; mm

Stability in the z-direction; Braced

Stability in the y-direction; Braced

Concrete details

Concrete strength class; C30/37

Partial safety factor for concrete (2.4.2.4(1)); γC = 1.50

Coefficient αcc (3.1.6(1)); αcc = 0.85

Maximum aggregate size; dg = 20 mm

Reinforcement details

Nominal cover to links; cnom = 35 mm

Longitudinal bar diameter; ϕ = 20 mm

Link diameter; ϕv = 8 mm

Total number of longitudinal bars; N = 6

No. of bars per face parallel to y-axis; Ny = 2

No. of bars per face parallel to z axis; Nz = ;3

Area of longitudinal reinforcement; As = N × π × ϕ2 / 4 = 1885 mm2

Characteristic yield strength; fyk = 500 N/mm2

Partial safety factor for reinft (2.4.2.4(1)); γS = 1.15

Es = 200000 MPa

Column effective lengths

Effective length for buckling about y-axis; l0y = 3500 mm

Effective length for buckling about z-axis; l0z = 3900 mm

Effective depths of bars for bending about y-axis

Area per bar; Abar = π × ϕ2/4 = 314 mm2

Spacing of bars in faces parallel to z-axis (centre to centre);

sz = h – 2 × (cnom + ϕv) – ϕ)/ (Nz – 1) = 172 mm

Layer 1 (in tension face); dy1 = h – cnom – ϕv – ϕ/2 = 397 mm

Layer 2; dy2 = dy1 – sz = 225 mm

Layer 3; dy3 = dy2 – sz = 53 mm

2nd moment of area of reinforcement about y axis;

Isy = 2 × Abar × [Ny × (dy1 – h/2)2] = 3718 cm4

Radius of gyration of reinforcement about y-axis; isy = √(Isy/As) = 140 mm

Effective depth about y axis (5.8.8.3(2)); dy = h/2 + isy = 365 mm

Effective depths of bars for bending about z-axis

Area of per bar; Abar = π × ϕ2 / 4 = 314 mm2

Spacing of bars in faces parallel to y axis (c/c); sy = (b – 2 × (cnom + ϕv) – ϕ) / (Ny – 1) = 144 mm

Layer 1 (in tension face); dz1 = b – cnom – ϕv – ϕ/2 = 197 mm

Layer 2; dz2 = dz1 – sy = 53 mm

Effective depth about z axis; dz = dz1 = 197 mm

Column slenderness about y-axis

Radius of gyration; iy = h/√(12) = 13.0 cm

Slenderness ratio (5.8.3.2(1)); ly = l0y / iy = 26.9

Column slenderness about z-axis

Radius of gyration; iz = b/√(12) = 7.2 cm

Slenderness ratio (5.8.3.2(1));lz = l0z / iz = 54.0

Design bending moments

Frame analysis moments about y axis combined with moments due to imperfections (cl. 5.2 & 6.1(4))

Eccentricity due to geometric imperfections (y axis); eiy = l0y /400 = 8.8 mm

Min end moment about y-axis; M01y = min(|Mtopy|, |Mbtmy|) + eiyNEd = 33.8 kNm

Max end moment about y-axis; M02y = max(|Mtopy|, |Mbtmy|) + eiyNEd = 66.8 kNm

Slenderness limit for buckling about y axis (cl. 5.8.3.1)

A = 0.7

Mechanical reinforcement ratio; ω = As × fyd / (Ac × fcd) = 0.429

Factor B; B = √(1 + 2ω) = 1.363

Moment ratio; rmy = M01y / M02y = 0.506

Factor C; Cy = 1.7 – rmy = 1.194

Relative normal force; n = NEd / (Ac × fcd) = 0.706

Slenderness limit; llimy = 20 × A × B × Cy / √(n) = 27.1

ly < llimy – Second order effects may be ignored

Frame analysis moments about z-axis combined with moments due to imperfections (cl. 5.2 & 6.1(4))

Ecc. due to geometric imperfections (z axis); eiz = l0z /400 = 9.8 mm

Min end moment about z axis; M01,z = min(|Mtopz|, |Mbtmz|) + eizNEd = 18.7 kNm

Max end moment about z axis; M02,z = max(|Mtopz|, |Mbtmz|) + eizNEd = 24.5 kNm

Slenderness limit for buckling about y-axis (cl. 5.8.3.1)

A = 0.7

Mechanical reinforcement ratio; w = As × fyd / (Ac × fcd) = 0.429

Factor B; B = √(1 + 2ω) = 1.363

Moment ratio; rmz = 1.000

Factor C; Cz = 1.7 – rmz = 0.700

Relative normal force; n = NEd / (Ac × fcd) = 0.706

Slenderness limit; llimz = 20 × A × B × Cz / √(n) = 15.9

lz > llimz – Second order effects must be considered

Design bending moments (cl. 6.1(4))

Design moment about y axis; MEdy = max(M02y, NEd × max(h/30, 20 mm)) = 66.8 kNm

Local second order bending moment about z-axis (cl. 5.8.8.2 & 5.8.8.3)

Relative humidity of ambient environment; RH = 50 %

Column perimeter in contact with atmosphere; u = 1400 mm

Age of concrete at loading; t0 = 28 day

Parameter nu; nu = 1 + w = 1.429

nbal = 0.4

Approx value of n at max moment of resistance; nbal = 0.4

Axial load correction factor; Kr = min(1.0 , (nu – n) / (nu – nbal)) = 0.703

Reinforcement design strain; εyd = fyd/Es = 0.00217

Basic curvature; curvebasic_z = εyd / (0.45 × dz) = 0.0000245 mm-1

Notional size of column; h0 = 2 × Ac / u = 161 mm

Factor a1 (Annex B.1(1)); a1 = (35 MPa / fcm)0.7 = 0.944

Factor a2 (Annex B.1(1)); a2 = (35 MPa / fcm)0.2 = 0.984

Relative humidity factor (Annex B.1(1));

ϕRH = [1 + ((1 – RH/100%) / (0.1 mm-1/3 × (h0)1/3)) × a1] × a2 = 1.838

Concrete strength factor (Annex B.1(1));

βfcm = 16.8 × (1 MPa)1/2 / √(fcm) = 2.725

Concrete age factor (Annex B.1(1));

βt0 = 1 / (0.1 + (t0 / 1 day)0.2) = 0.488

Notional creep coefficient (Annex B.1(1));

ϕ0 = ϕRH × βfcm × βt0 = 2.446

Final creep development factor; (at t = ∞); βc∞ = 1.0

Final creep coefficient (Annex B.1(1));ϕ∞ = ϕ0 × βc∞ = 2.446

Ratio of SLS to ULS moments rMz (say) = 0.80

Effective creep ratio (5.8.4(2)); fefz = f∞ × rMz = 1.957

Factor β; βz = 0.35 + fck / 200 MPa – lz / 150 = 0.140

Creep factor; Kϕz = max(1.0, 1 + βz × ϕefz) = 1.273

Modified curvature; curvemod_z = Kr × Kϕz × curvebasic_z = 0.0000219 mm-1

Curvature distribution factor; c = 10

Deflection; e2z = curvemod_z × l0z2/c = 33.4 mm

Nominal 2nd order moment;

M2z = NEd × e2z = 45.1 kNm

Design bending moment about z-axis (cl. 5.8.8.2 & 6.1(4))

Equivalent moment from frame analysis;

M0ez = max(0.6 × M02z + 0.4 × M01z, 0.4 × M02z) = 22.2 kNm

Design moment;

MEdz = max(M02z, M0ez + M2z, M01z + 0.5 × M2z, NEd × max(b/30, 20 mm))

MEdz = 67.2 kNm

Moment capacity about y-axis with axial load (1350.0 kN)

Moment of resistance of concrete

By iteration:

Position of neutral axis; y = 317.8 mm

Concrete compression force (3.1.7(3));

Fyc = h × fcd × min(lsb × y, h) × b = 1080.6 kN

Moment of resistance;

MRdyc = Fyc × [h / 2 – (min(lsb × y, h)) / 2] = 105.8 kNm

Moment of resistance of reinforcement

Strain in layer 1; εy1 = εcu3 × (1 – dy1/y) = -0.00087

Stress in layer 1; σy1 = max(-1 × fyd, Es × εy1) = -174.4 N/mm2

Force in layer 1; Fy1 = Ny × Abar × σy1 = -109.6 kN

Moment of resistance of layer 1; MRdy1 = Fy1 × (h/2 – dy1) = 18.8 kNm

Strain in layer 2; εy2 = εcu3 × (1 – dy2 / y) = 0.00102

Stress in layer 2; σy2 = min(fyd, Es × εy2) – h × fcd = 187.4 N/mm2

Force in layer 2; Fy2 = 2 × Abar × σy2 = 117.8 kN

Moment of resistance of layer 2; MRdy2 = Fy2 × (h/2 – dy2) = 0.0 kNm

Strain in layer 3; εy3 = εcu3 × (1 – dy3/y) = 0.00292

Stress in layer 3; σy3 = min(fyd, Es × εy3) – h × fcd = 417.8 N/mm2

Force in layer 3; Fy3 = Ny × Abar × σy3 = 262.5 kN

Moment of resistance of layer 3; MRdy3 = Fy3 × (h/2 – dy3) = 45.2 kNm

Resultant concrete/steel force; Fy = 1351.2 kN

PASS – This is within half of one percent of the applied axial load

Combined moment of resistance

Moment of resistance about y axis; MRdy = 169.8 kNm

PASS – The moment capacity about the y axis exceeds the design bending moment

Moment capacity about z-axis with axial load (1350.0 kN)

Moment of resistance of concrete

By iteration, position of neutral axis; z = 171.9 mm

Concrete compression force (3.1.7(3)); Fzc = h × fcd × min(lsb × z, b) × h = 1051.9 kN

Moment of resistance; MRdzc = Fzc × [b / 2 – (min(lsb × z, b)) / 2] = 59.2 kNm

Moment of resistance of reinforcement

Strain in layer 1; εz1 = εcu3 × (1 – dz1 / z) = -0.00051

Stress in layer 1; σz1 = max(-1 × fyd, Es × εz1) = -102.3 N/mm2

Force in layer 1; Fz1 = Nz × Abar × σz1 = -96.4 kN

Moment of resistance of layer 1; MRdz1 = Fz1 × (b / 2 – dz1) = 6.9 kNm

Strain in layer 2; εz2 = εcu3 × (1 – dz2/z) = 0.00242

Stress in layer 2; σz2 = min(fyd, Es × εz2) – h × fcd = 417.8 N/mm2

Force in layer 2; Fz2 = Nz × Abar × σz2 = 393.8 kN

Moment of resistance of layer 2; MRdz2 = Fz2 × (b/2 – dz2) = 28.4 kNm

Resultant concrete/steel force; Fz = 1349.2 kN

PASS – This is within half of one percent of the applied axial load

Combined moment of resistance

Moment of resistance about z-axis; MRdz = 94.5 kNm

PASS – The moment capacity about the z-axis exceeds the design bending moment

Biaxial bending

Determine if a biaxial bending check is required (5.8.9(3))

Ratio of column slenderness ratios; ratiol = max(ly, lz) / min(ly, lz) = 2.01

Eccentricity in direction of y axis; ey = MEdz/NEd = 49.8 mm

Eccentricity in direction of z axis; ez = MEdy/NEd = 49.5 mm

Equivalent depth; heq = iy × √(12) = 450 mm

Equivalent width; beq = iz × √(12) = 250 mm

Relative eccentricity in direction of y-axis; erel_y = ey/beq = 0.199

Relative eccentricity in direction of z-axis; erel_z = ez/heq = 0.110

Ratio of relative eccentricities;

ratioe = min(erel_y, erel_z)/max(erel_y, erel_z) = 0.552

ratiol > 2 and ratioe > 0.2

Therefore, biaxial bending check is required.

Biaxial bending (5.8.9(4))

Design axial resistance of section; NRd = (Ac × fcd) + (As × fyd) = 2732.0 kN

Ratio of applied to resistance axial loads; ratioN = NEd / NRd = 0.494

Exponent a; a = 1.33

Biaxial bending utilisation; UF = (MEdy/MRdy)a + (MEdz/MRdz)a = 0.926 (Okay)

Shear

Design shear force; VEd = VEd,y = 25.8 kN

CRd,c = 0.18/γC = 0.12

Tension reinforcement; Asl = Nz × π × ϕ2/4 = 942 mm2

Depth of tension reinforcement; dv = dz1 = 197 mm

kshear = min(1 + (200 mm / dv)0.5, 2) = 2.000

Width of the cross section in tensile area; bw = h = 450 mm

Longitudinal reinforcement ratio; rl = min(Asl/(bw × dv), 0.02) = 0.01063

Axial pressure in cross-section; σcp = min(NEd/Ac, 0.2 × fcd) = 3.40 N/mm2

vmin = 0.035 N0.5/mm × kshear3/2 × fck1/2 = 0.54 N/mm2

k1,shear = 0.15

Design shear resistance – exp. 6.2 a & b;

VRd,c = max(CRd,c × kshear × (100 N2/mm4 × rl × fck)1/3, vmin) × bw × dv + k1,shear × σcp × bw × dv = 112.7 kN

VEd / VRd,c = 0.23

PASS – Design shear resistance exceeds design shear force

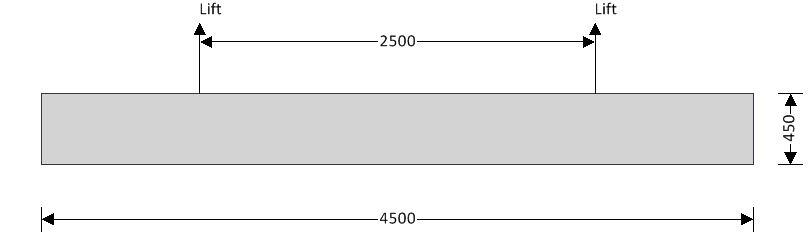

Factory Lifting Check

Precast element details

Total length of column; Lelement = 4500 mm

Distance between lifting points; Llift = 2500 mm

Lifting load coefficient; flifting = 1.50

Permanent load factor; γG = 1.35

Formwork adhesion force; qformwork = 2.0 kN/m2

Self weight of precast element; wself_precast = b × h × ρconc × gacc + qformwork × b = 3.3 kN/m

Lifting check (positive moment)

Design bending moment; M = γG × flifting × (wself_precast × Llift2 /8 – wself_precast × ((Lelement – Llift) / 2)2/2) = 1.9 kNm

Effective depth of tension reinforcement; d = 397 mm

Redistribution ratio; d = 1.000

K = M / (b × d2 × fck) = 0.002

No compression reinforcement is required

Lever arm; z = min(0.5 × d × (1 + (1 – 2 × K / (h × acc / γC))0.5), 0.95 × d) = 377 mm

Depth of neutral axis; x = 2 × (d – z)/lsb = 50 mm

Area of tension reinforcement required; As,pos = M / (fyd × z) = 11 mm2

Tension reinforcement provided; 2H20 mm (As,prov = 628 mm2)

Minimum area of reinforcement – exp.9.1N; As,min = max(0.26 × fctm/fyk, 0.0013) × b × d = 149 mm2

Maximum area of reinforcement – cl.9.2.1(3); As,max = 0.04 × b × h = 4500 mm2

Required area of reinforcement; As,req = 149 mm2

As,req / As,prov = 0.24 (okay)

Lifting check (negative moment)

Design bending moment; M = γG × flifting × wself_precast × ((Lelement – Llift) / 2)2 / 2 = 3.3 kNm

Effective depth of tension reinforcement; d = 397 mm

Redistribution ratio; d = 1.000

K = M / (b × d2 × fck) = 0.003

Area of tension reinforcement required; As,neg = M / (fyd × z) = 20 mm2

Tension reinforcement provided; 2H20 mm (As,prov = 628 mm2)

Minimum area of reinforcement – exp.9.1N; As,min = max(0.26 × fctm/fyk, 0.0013) × b × d = 149 mm2

Maximum area of reinforcement – cl.9.2.1(3); As,max = 0.04 × b × h = 4500 mm2

Required area of reinforcement; As,req = 149 mm2

As,req / As,prov = 0.24 (Okay)

Lifting check (Shear)

Design shear force at critical shear plane;

VEd = γG × flifting × wself_precast × max(Llift / 2, (Lelement – Llift) / 2) = 8.2 kN

CRd,c = 0.18/γC = 0.12

Tension reinforcement; Asl = Ny × π × ϕ2 / 4 = 628 mm2

Depth of tension reinforcement; dv = dy1 = 397 mm

kshear = min(1 + (200 mm / dv)0.5, 2) = 1.710

Width of the cross section in tensile area; bw = b = 250 mm

Longitudinal reinforcement ratio; ρl = min(Asl / (bw × dv), 0.02) = 0.00633

vmin = 0.035 N0.5/mm × kshear3/2 × fck1/2 = 0.43 N/mm2

Design shear resistance – exp. 6.2 a & b;

VRd,c = max(CRd,c × kshear × (100 N2/mm4 × ρl × fck)1/3, vmin) × bw × dv

VRd,c = 54.3 kN

VEd / VRd,c = 0.15 (This is okay)

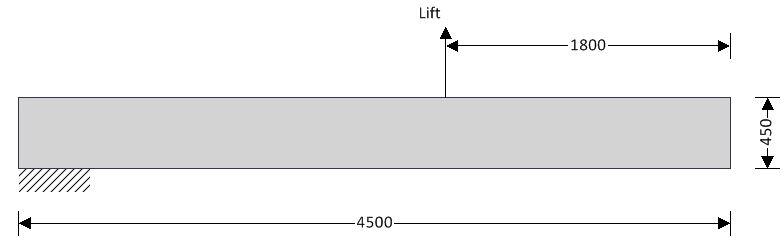

On-site Pitching Check

Precast element details

Total length of column; Lelement = 4500 mm

Distance to the pitching point; Lpitch = 1800 mm

Distance from pitching point to end of column;Lend = 2700 mm

Lifting load coefficient; fpitching = 1.25

Permanent load factor; gG = 1.35

Self weight of precast element; wself_precast = b × h × ρconc × gacc = 2.8 kN/m

Lifting check (positive moment)

Design bending moment (at 3750 mm);

M = gG × fpitching × wself_precast × Lelement2 / (2 × Lend) × (0.25 × Lelement2/Lend – Lpitch) = 1.3 kNm

Effective depth of tension reinforcement; d = 397 mm

Redistribution ratio; d = 1.000

K = M / (b × d2 × fck) = 0.001

Area of tension reinforcement required; As,pos = M / (fyd × z) = 8 mm2

Tension reinforcement provided; 2H20 mm (As,prov = 628 mm2)

Minimum area of reinforcement – exp.9.1N; As,min = max(0.26 × fctm/fyk, 0.0013) × b × d = 149 mm2

Maximum area of reinforcement – cl.9.2.1(3); As,max = 0.04 × b × h = 4500 mm2

Required area of reinforcement; As,req = 149 mm2

As,req / As,prov = 0.24 (Okay)

Lifting check (negative moment)

Design bending moment; M = gG × fpitching × wself_precast × Lpitch 2 / 2 = 7.5 kNm

Effective depth of tension reinforcement; d = 397 mm

Redistribution ratio; d = 1.000

K = M / (b × d2 × fck) = 0.006

Area of tension reinforcement required; As,neg = M / (fyd × z) = 46 mm2

Tension reinforcement provided; 2H20 mm (As,prov = 628 mm2)

Minimum area of reinforcement – exp.9.1N; As,min = max(0.26 × fctm/fyk, 0.0013) × b × d = 149 mm2

Maximum area of reinforcement – cl.9.2.1(3); As,max = 0.04 × b × h = 4500 mm2

Required area of reinforcement; As,req = 149 mm2

As,req / As,prov = 0.24 (Okay)

Lifting check (Shear)

Design shear force at critical shear plane;

VEd = gG × fpitching × wself_precast × max(Lpitch, abs(Lelement – 0.5 × Lelement2 / Lend), abs(Lend – (Lelement – 0.5 × Lelement2 / Lend))) = 9.1 kN

CRd,c = 0.18/γC = 0.12

Tension reinforcement; Asl = Ny × π × ϕ2 / 4 = 628 mm2

Depth of tension reinforcement; dv = dy1 = 397 mm

kshear = min(1 + (200 mm / dv)0.5, 2) = 1.710

Width of the cross section in tensile area; bw = b = 250 mm

Longitudinal reinforcement ratio; ρl = min(Asl / (bw × dv), 0.02) = 0.00633

vmin = 0.035 N0.5/mm × kshear3/2 × fck1/2 = 0.43 N/mm2

Design shear resistance – exp. 6.2 a & b;

VRd,c = max(CRd,c × kshear × (100 N2/mm4 × ρl × fck)1/3, vmin) × bw × dv

VRd,c = 54.3 kN

VEd / VRd,c = 0.17 (Okay)

Connection

The connection of the column can be designed and checked depending on the method adopted.