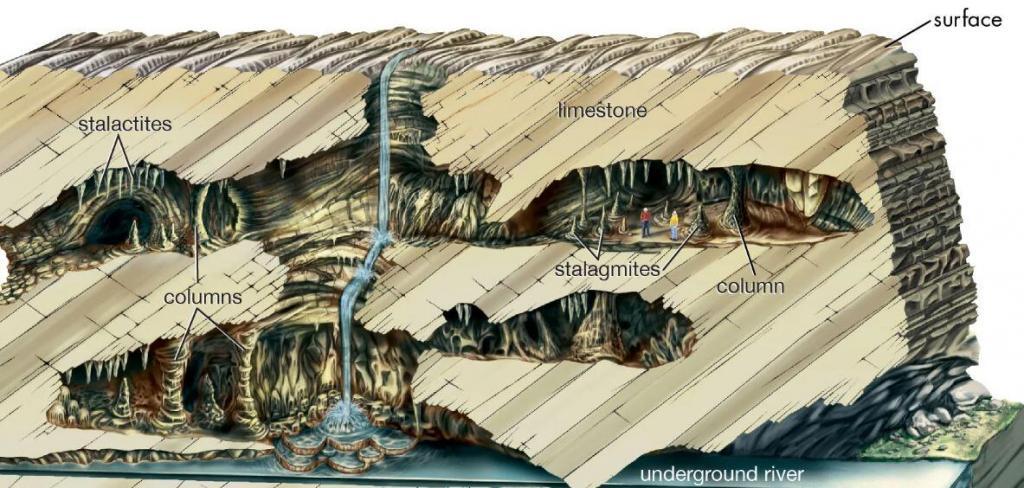

The presence of well-developed solution channels, caves, springs, sinkholes, and extremely irregular weathered bedrock surfaces with cavities are the characteristics of a karstic topography. Sinkholes are “closed depressions” in the earth’s surface that are created when limestone and other rocks close to the surface dissolve and the material on top of them subside or collapses into subsurface solution caverns.

When infiltrating acidic water comes into prolonged contact with limestone, sinkholes often result. For obvious reasons, sinkholes are the major geologic hazard in karst terrain. They can cause structural damage and failure of buildings, cut off highways, drain ponds and lakes, and allow direct infiltration of contaminated groundwater.

Sinkholes are the result of a slow, continuous process. However, the effects of the sinkhole near the surface can occur suddenly and catastrophically. There are two types of sinkholes:

i) Collapse Sinkhole, and

ii) Subsidence Sinkhole

Collapse Sinkholes

Collapse sinkholes develop when the limestone’s solution forms a vertical cavern or throat below the surface of the ground. Initially, the surface soil may be strong enough to span across the cavern. The bridging soils will eventually crumble as the cavern widens over time. Most people have heard about sinkholes in the media in terms of this.

Subsidence sinkholes

When the soil is relatively granular above the limestone formation, sinkholes might arise. In this situation, as the limestone erodes, the earth material on top fills the spaces left behind. This is known as ravelling, and if the earth keeps ravaging into the spaces in the limestone, the ground will eventually sink and produce a sinkhole.

The size of sinkholes can be influenced by the thickness of the overlying layer. The overlaying stratum can span a bigger cavern if it is sufficiently thick. For a collapse to occur, the cavern must enlarge. Additionally, sinkholes can grow to sizes large enough to engulf entire buildings.

Site Investigation for Sinkholes

Rocks that are prone to solutioning activity are known to underlie around one-fourth of the earth’s crust (Syed, 2004). Numerous reports of issues with construction on karst sites have been made worldwide. Similarly, reports have been made on the sudden collapse of previously undetected solution cavities that have caused harm to existing structures and infrastructures.

It goes without saying that thorough subsurface investigations are required when significant structures are to be found in karstic regions. However, it is still true that it might be challenging to find possible sinkholes, caverns, or solutioning activity that have not yet affected the ground surface.

Because a borehole only examines a small region, the typical geotechnical study method of drilling holes may not be able to find them. Experience has shown that utilizing borings to locate sinkholes or cavities is only 10% to 20% accurate.

Studying the local geology and hydrogeology and mapping sinkholes that have already formed in the project area are the first steps in the investigation of sinkhole potential. Both surface geophysical approaches and boreholes will need to be used for the large-scale site investigation.

The typical approach should be to use borehole methods for detection and delineation and surface methods for early reconnaissance (anomaly detection). In other words, the zone in question should be drilled and sampled to give observations for the purpose of evaluation when aberrant responses are recorded during the surface surveys.

Various approaches to investigating Karstic features are:

• Aerial and Satellite Photography

• Backhoe Trenches

• Drilling boreholes

• Modern Geophysical Techniques

Aerial and Satellite Photography

Identifying probable sinkholes can be done through aerial surveys. Large-scale zones of subsidence may be visible on old aerial photographs, which may aid in locating smaller, localized sinkholes. Although they can be located on the ground, an aerial survey is more practical.

Backhoe Trenches

Backhoes can easily and quickly explore a relatively large area. Trenches done this way can expose near-surface solution voids or sinkhole throats. However, they can not completely replace information obtained from a borehole.

Drilling Boreholes

Test borings are an important part of sinkhole or cavity investigations. The holes are drilled to the bedrock even if this requires drilling to much greater depths than would be necessary, otherwise. Standard Penetration Tests (SPTs) are usually conducted as the bore advances. This helps in knowing the strengths of various sediment layers. The data is used to draw subsurface cross-sections that help in inferring the presence or absence of sinkholes or cavity-associated features.

Geophysical Surface Surveys

A number of such techniques are currently in vogue that can locate cavities and sinkholes. The idea behind such techniques is to probe the subsurface without disturbing the ground surface. This is done by generating a wave, which when propagated through the soil, reveals anomalies. This can be investigated to find if the same is the presence of cavities or not.

Sinkhole Management in Construction – Case Study of Saudi Arabia

Syed (2004) published a case study about the Prince Abdullah Military City Project Site, which is in the oasis of Al-Hassa, in the Eastern Province of the Kingdom of Saudi Arabia, some 12 km west of the city of Hofuf. The report was published and presented during the fifth International Conference on Case Histories in Geotechnical Engineering, April 2004.

According to Syed (2004), there are several bedrock cavities at the project site. Numerous Reports, including those written in 1992 by a geotechnical consultant for a small area of the subject Site and those completed by the US Army Corps of Engineers in 1978, have documented these conclusions for the subject site.

The following terms best describe the karstic features seen at the project site: collapse sinkholes, subsidence sinkholes, dropouts, and bedrock cavities. In order to find and map the bedrock cavities at the site, a rigorous soil investigation program was launched. In-situ testing and sampling of overburden soil by Standard Penetration Tests (SPTs) and coring in the bedrock strata were all parts of the detailed geotechnical investigation program that was carried out at the site for the purpose.

Additionally, Core Recovery and Rock Quality Designation (RQD) measurements were made. Testing typical samples of subsurface materials in the lab was also included. To further confirm the competency of the stratum below, a thorough “Cavity Search Probing” was also carried out under the footprints of each building. With the aid of a wagon drill and “Pneumatic Driving,” a rock probe was driven into the bedrock while being cleaned out of the hole as it went.

The “Karstic Terrain” at the project site was mapped with the aid of these investigation and probing. The information was also helpful in developing plans for the project’s remediation and later construction. Given the karstic issues at the project site, a semi-rigid raft foundation was chosen. This foundation system became the best option for the situation because it is known for being quite robust to bridge over the underlying cavities.

Sinkhole Investigation at the Site

The Project Site spans an area of around 6 square kilometers and is divided into 8 zones. An initial preliminary reconnaissance investigation was conducted at the site, followed by a detailed investigation for each of the 8 Zones. There were already two investigations conducted at the project site prior to the preliminary reconnaissance investigation (conducted in March 1998), each conducted by a different agency at a different time. The range of work for the various investigations carried out at the project site can be found in Syed (2004).

All of these tests at the project site proved that the limestone that makes up the bedrock is primarily light brown, fine-grained, strongly to moderately worn, and jointed. The underlying rock strata’s Total Core Recovery (TCR), which generally exceeds 50%, was determined to be between 27% and 100%. However, the Rock Quality Designation (RQD), which ranged from 0% to 100%, was typically lower than 20%.

The presence of several small cavities inside the underlying limestone bedrock is one of this limestone’s common characteristics that has been mentioned in all the studies. The findings advised performing a thorough Cavity Probing after excavation during the building stage at the locations of the foundations (under the footprints of the facilities). Drilling probing holes at least 1.5 times the width of the foundations deep is the best way to accomplish this.

The following methods were applied at the project site to investigate the local geology and hydrogeology as well as to find and map probable sinkholes and cavities.

• Trenches and Test Pits

• Drilling Boreholes, and

• Cavity Probing using pneumatic driving of Probe.

Trenches, test pits, and boreholes were used to collect a lot of information that indicated the presence of bedrock cavities beneath the surface. However, before starting to pour the foundations, a thorough cavityprobing was done beneath the footprints of each facility to determine whether or not there were any cavities. 5,610 probe holes total (in 166 facilities in 6 zones) were made. This comprised an extra 219 numbers in 18 numbers of facilities located surrounding the problematic locations.

The Cavity search program was quite thorough and detailed. The probing was done by using a wagon drill to pneumatically drive a rock probe into the rock. As time went by, compressed air was utilized to clear the hole. The probe’s time through each successive 20 cm depth was meticulously measured to determine the rock’s resistance to penetration.

The time for penetration records will be quite short if there are cavities or loose zones in the underlying strata. For a 20 cm penetration, a time of less than 10 seconds is regarded as the presence of loose zones, however in the case of a cavity, there will be no resistance to rock penetration and it happens suddenly.

In the course of this operation, the following details were meticulously recorded:

• Time taken for 20 cm penetration

• Air escape in the finished boreholes

• Sudden fall of drill rod

• Boreholes, where time was 10 seconds or less

Any bore where the previous three observations were made were probed repeatedly until a cavity was identified or some logical explanations for the observations were found. If there were any cavities, grout was used to fill them in. To reveal the sinkholes or cavities, excavations were also carried out in the vicinity of these problem probing holes.

Treatment and Remedial Measures

The methods used to remedy Karst-related features may be as diverse as the cavities and sinkholes themselves. In order to expose the opening in the rock surface, the overburden soils must be removed if the “throat” of a sinkhole can be found.

The excavation is then backfilled once the throat has been sealed off or covered with an inverted filter. A less effective treatment is typically employed if the throat cannot be found or if the depth of the rock makes exposing the rock surface impractical.

The excavation base could subsequently be sealed with concrete and/or the entire region could be covered with a geotextile if a throat is discernible but the depth to rock is excessive. If there is no neck visible and the rock is too deep, the only practicable remedy is to remove soft or organic materials, cover the region with a geotextile, and then re-fill the hole with clayey soils.

The project site’s sinkhole and cavity issues, however, required a variety of treatments and corrective actions due to the unique site characteristics.

This can be grouped as:

i) during leveling and grading

ii) during foundation construction, and

iii) during external works construction, like roads, water supply, sanitary sewer, storm water drainage, and other items related to landscaping and irrigation works.

With the exception of a few, the majority of the sinkholes and cavities discovered during foundation construction were outside the footprints of the facilities. Large open-mouthed sinkholes of about 5m × 4m x 3m deep were discovered inside the footprint of some foundation areas. These were overexcavated to reveal the size of the cavities, and then compaction grouting was used to cure them. This innovative method, which is known as “the Grout injected with a slump less than 25 mm,” was developed in the USA.

Typically, a soil-cement mixture with large amount of silt particles to give plasticity and create internal friction is utilized in this. In most cases, grout does not penetrate soil pores; instead, it stays in a homogenous mass that allows for controlled displacement. Additionally, regular grout was employed to address the issue in this facility. Some of them were also backfilled with rock using a bridging technique.

Due to the short duration observed for a 20 cm probe penetration during a cavity search probe, there was suspicion of the presence of sinkholes or cavities in some other facilities. Therefore, more investigations were conducted to confirm the suspicions. Except for two sites, the time recorded for the additional probes in most cases did not record fewer than 10 seconds.

Deep excavations have to be done for the service pits and hydraulic lift pits at some of the facilities. These extra probing were nearby and had time records of less than 10 seconds, which suggested the presence of cavities. Therefore, it was determined to over-excavate the limited area in order to explore the underground caverns.

The cavities were exposed during excavation, along with several lateral solution channels. These were completely cleaned before being treated using two different techniques:

(i) Compaction grouting of the vertical cavities, and

(ii) Bridging utilizing boulders and geotextiles to seal the mouth of the lateral solution channels.

Foundation Design Considerations

Even with the best techniques and designs, construction in karst terrain is unquestionably not risk free, according to experts on the issue. However, the risk they pose justifies the search for a remedy that lowers the risks at a reasonable cost.

The solution in vogue are outlined as follows;

• Optimize the location on the site

• Treat defects that are present

• Use modified shallow foundations

• Use deep foundations

• Minimize future activation

For medium-sized buildings, the use of modified shallow foundations is a practical solution to the problems of Karstic hazards.

Utilizing such foundations involves:

(i) constructing a footing that spans or bridges over the cavity; and

(ii) constructing a mat foundation that is rigid enough to minimize deflections that may occur due to Sinkhole formation beneath it.

The proposal accepted for the project site is a semi-rigid raft foundation. It has thicker borders or raft bands and resembles a mat. This was implemented in the project to get around the site’s sinkhole and cavern issues. This can span the cavities because it is sufficiently stiff. The same was analyzed and designed using PCA-MATS. A bearing capacity of 150 kN/m2 was used to design the foundations in accordance with the Geotechnical Report. Given the rock’s worn state and the karstic terrain, a relatively low figure of bearing capacity was advised.

Conclusion

Sinkholes are geologic hazards that can pose enormous risk to the safety of infrastructures. Extensive geotechnical site investigation is required when there is a possibility of the existence of sinkholes and cavities in an area. In a report presented by Syed (2004), a Karstic terrain was encountered in a project site in Al Hofuf, Saudi Arabia.

The detection, delineation, and mapping of bedrock cavities, sinkholes, dropouts, and solution channels were the subject of a thorough investigative program. Under the footprints of 166 facilities in 6 zones, 316 boreholes, 10 test pits, and 5610 cavity probe holes were drilled. By employing a Wagon Drill to pneumatically drive a rock probe, the cavity was probed. As time went by, compressed air was utilized to clear the hole.

The site’s karstic features were mapped, and remediation efforts were made. The majority of the sinkholes and voids were filled in using grout, with the use of geotextiles in other locations. A novel method of compaction grouting was used to fix some of them. Some of them were also “plugged” with rock utilizing the bridging method. By creating masonry and/or concrete structures, the voids and lateral solution channels in utility trenches were sealed. The roadways’ ditches were paved.

The Site’s treated karstic features are functioning effectively, and for the past four years or more, no problems have been reported. A hard and shallow style of foundation called a semi-rigid raft foundation was employed. Such footings are suggested by experts because of their capacity to span the cavities.

Reference Article:

Syed, Ahmad Faiz, “Managing Sinkholes at Project Site, A Saudi Arabian Case History” (2004). International Conference on Case Histories in Geotechnical Engineering. 20. https://scholarsmine.mst.edu/icchge/5icchge/session06/20

At competitive pricing, we are supplying quality geotechnical and exploration drilling equipment and tools based in China.

OK Noted!!!!