Different techniques can be used for strengthening concrete slabs that have been deemed structurally unsound or inadequate to withstand a specified floor loading. Some of the methods usually adopted for slab strengthening are; concrete overlay, adding steel sections, adding reinforced concrete beam sections, or FRP reinforcing.

These techniques for slab strengthening have been developed due to a number of reasons such as poor maintenance of structures, overloading of reinforced concrete members, corrosion of the steel reinforcement, and other deteriorating conditions that develop over time in reinforced concrete structures.

Generally, reinforced concrete slabs may need to be repaired or strengthened in the following circumstances;

a) Repairing damaged/deteriorated concrete slabs to restore their strength and stiffness.

b) Corrosion of the reinforcement.

c) Limiting crack width under increased (design/service) loads or sustained loads.

d) Retrofitting concrete members to enhance the flexural strength and strain to failure of concrete elements requested by increased loading conditions such as earthquakes or traffic loads.

e) Rectifying design and construction errors such as undersized reinforcement.

f) Enhancing the service life of the RC slabs.

g) Shear strengthening around columns for increasing the perimeter of the critical section for punching shear.

h) Changes in the structural system such as cut-outs in the existing RC slabs.

i) Changes in the design parameters.

j) Optimization of structure regarding the reduction of deformations and of stresses in the reinforcing bars.

Depending on the architectural requirements, functionality, and convenience of construction, a combination of two or more strengthening techniques may also be utilized, where one approach is used at the top and another technique is used to strengthen the slab bottom soffit.

In order to strengthen a slab, it may also be necessary to reduce the straining actions by incorporating new structural components, such as concrete or steel beams or columns. A reinforced concrete slab may also be strengthened for the purpose of improving the flexural moment or punching shear resistance.

By increasing the stiffness, slabs can be strengthened to improve their serviceability limit states by reducing deflection, controlling crack width, and improving the behaviour in vibration. Furthermore, strengthening might be added to increase the slab’s fire resistance.

Concrete Overlay for Slab Strengthening

Depending on which areas of the slab need strengthening, concrete overlays are constructed on either the top, bottom, or both surfaces. Although the top of the slab’s concrete overlay is simpler to construct, the bottom of the slab’s overlay could also be done while concrete is cast using shotcrete to ensure that there are no honeycomb or voids in the overlay.

The most important concern with the concrete overlay method is ensuring a proper bond between the “new” concrete used to strengthen the structure and the “old” concrete in the existing structure. The shrinkage of these two concretes must be taken into particular consideration.

However, it is generally acknowledged that strengthening by adding a new layer of reinforced concrete is considerably simpler to do when the operation is done on the top surface of the slab. Experience has shown that it is usually necessary to add new reinforced concrete to the member’s bottom face, particularly in the areas where they experience positive bending moments. Shotcrete or specific formwork must be used to pour concrete on the bottom face.

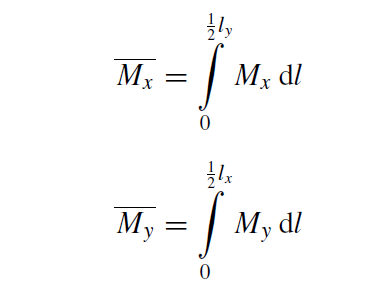

For general construction purposes, using a concrete overlay at the top and strengthening the slab’s positive moment section with steel plates or CFRP reinforcement may be more cost-effective. When doing a concrete overlay, steel dowels are inserted to transfer the interfacial shear forces between the old and new concrete when the slab is propped up to support both its own weight and the weight of the overlay.

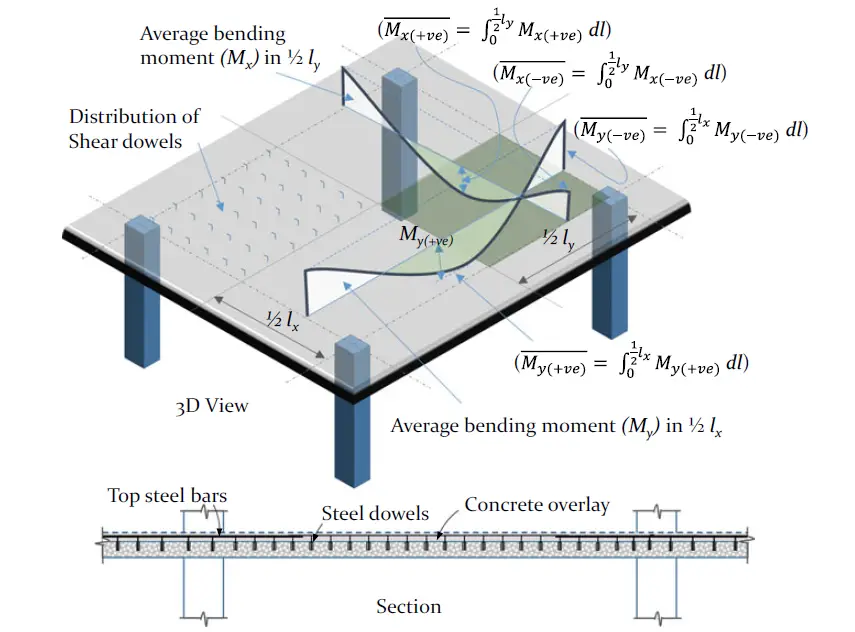

According to Abdelrahman (2023), the total area of steel shear dowels planted in one-quarter of the slab panel (0.5lx × 0.5ly), as per the Figure above can be calculated based on the bending moments in the x and y directions integrated within half the slab length/width (Ṁx and Ṁy) as shown in the equations below.

The induced forces on the shear dowels in the x and y directions (Fx, Fy), can be calculated using the equations below for both the positive and negative bending moments independently. The total force on the shear dowels in one-quarter of the slab panel (Fs) is calculated after adding the forces in both directions (x and y) resulting from the positive and the negative moments. After which, the area of steel shear dowels can be calculated.

Slab strengthening by External Reinforcement

External steel plates, externally bonded FRP laminates, or near-surface-mounted FRP reinforcement can all be used to strengthen concrete slabs. Depending on the slab’s aspect ratio and the need for strengthening, the external reinforcement may be applied in one direction or two directions.

This method also entails strengthening slab systems in an approach that combines the actions of steel plates and steel bolts. In some cases, steel bolts can be arranged in a manner that is similar to how shear studs are arranged, when they are to be used as vertical shear reinforcements. Steel plates are then attached to the concrete surface at the upper and lower sides of the slab using epoxy glue and tightened with steel bolts and nuts.

So, in addition to providing vertical shear reinforcement, the purpose of the steel bolts is to ensure complete contact between the steel plates and concrete slab by transmitting horizontal force between the two materials and applying confinement pressure to the concrete. Hence, the suggested reinforcing method consists of integrating steel plates, steel bolts, and applying pressure to the slab to confine them.

Steel plates may be mounted to the top of the slab and FRP strips may be fastened to the slab’s bottom soffit using various reinforcing techniques on the same slab. As opposed to working overhead for the bottom surface, installing the steel strips and inserting the dowels from the top of the slab is easier. The area of steel dowels needed is calculated using the formula provided for slabs reinforced with concrete overlay.

To prevent corrosion of the exterior steel plates in the event that they are applied in two directions, care should be taken to fill the space behind the steel plates with filler material, such as grout or epoxy grout.

Slab strengthening by adding structural member

Furthermore, concrete or steel structural members, such as a column or beam, can be added to strengthen slabs. In order to divide the slab into smaller portions and increase its stiffness, the structural arrangement of the slab is altered by the addition of columns or beams.

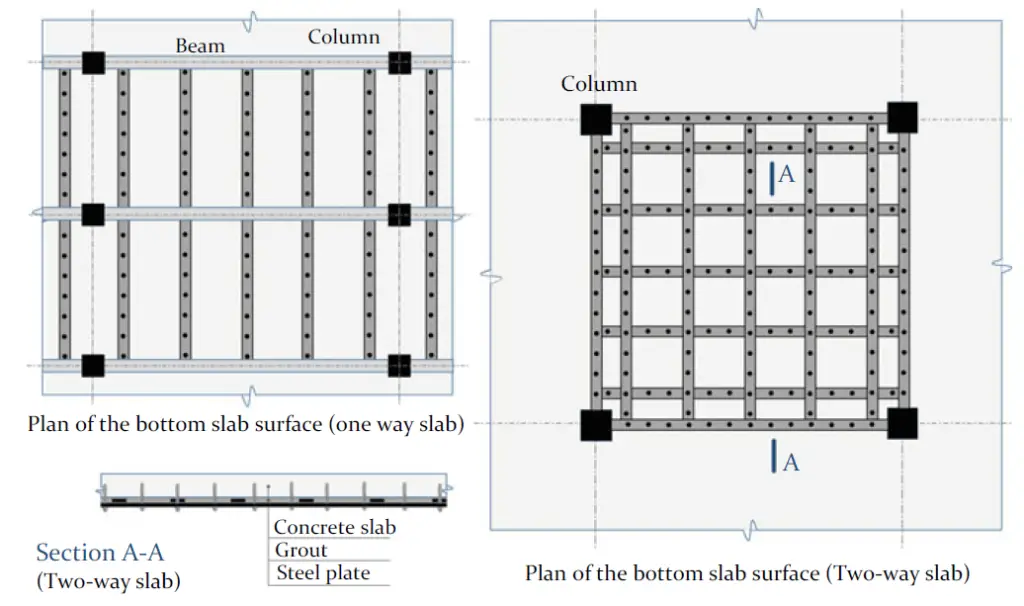

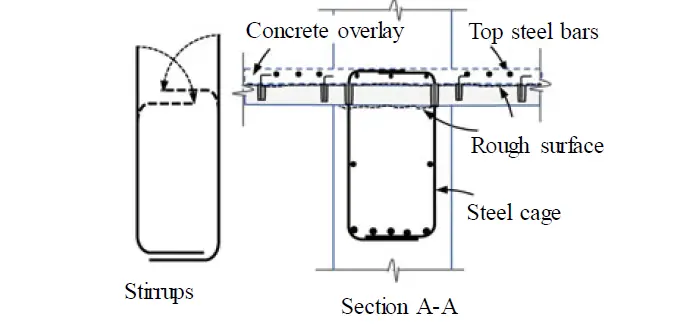

After the new member is added, the straining actions and deformations of the slabs will be reduced. As shown in Figure 4, installing concrete beams to support pre-existing slabs needs drilling in the slabs for the longitudinal reinforcement and the supporting elements for the transverse steel stirrups.

To reduce the interfacial shear stresses between the old and new concrete caused by concrete shrinkage, low-shrinkage admixtures are added to the concrete before it is cast after the steel cage has been assembled. In this case, the slab should either be jacked up to release the load off the slab or propped so that the props hold the weight of the concrete and the weights above.

Figure 5 shows the necessary steel reinforcement for the new beam in detail. Since the new beam will share the whole weights with the slabs, including the weight of the slab and the weights above, releasing the loads from the slab at the time of casting the new supporting beam would minimize the overall stresses in the slab.

Conclusion

Each of the techniques discussed in this article has a number of benefits and drawbacks. Some, such as concrete overlay, significantly increase the dead load of the structure and may necessitate additional strengthening of the other structural parts. On the other hand, the external plate bonding technique and is susceptible to corrosion damage which may lead to failure of the strengthening system.

However, the load-carrying capacity of reinforced concrete slabs can be increased using any of the strengthening methods, or the structural performance of the concrete parts can be at least partially restored. The magnitude of strengthening needed, the area where strengthening is needed, architectural requirements, ease and speed of application, and the overall cost will all affect the choice of the best technology to apply.

Reference

Abdelrahman A. (2023): Strengthening of Concrete Structures: Unified Design Approach, Numerical Examples and Case Studies. Springer Nature Singapore Pte Ltd. https://doi.org/10.1007/978-981-19-8076-3