Structural engineers usually issue bar bending schedule (BBS) to clients/contractors after completing the design and detailing of a reinforced concrete structure. Bar bending schedules usually show the length, shape, and quantity of reinforcements needed for a particular phase/element of a project.

The bar bending schedule issued by structural engineers after a design is usually very exact. In other words, engineers provide the exact quantity of steel needed to produce what they have shown in their drawing, without additional considerations. However, the primary challenge faced by contractors on site is the issue of offcuts, since rebars are usually supplied in 12 m length, and the cut length of reinforcements can vary depending on the element. Offcuts are not usually accounted for in the schedule issued by a structural engineer, and practically, not all offcuts are reusable.

In this case, there are usually two major challenges for the contractor;

(1) He can buy more reinforcement than given in the bending schedule to take care of the losses from offcuts. This usually requires additional calculations.

(2) If the contractor purchases reinforcements based on the bar bending schedule only, he risks requesting for supply twice, which will probably double his transportation cost.

Case Study

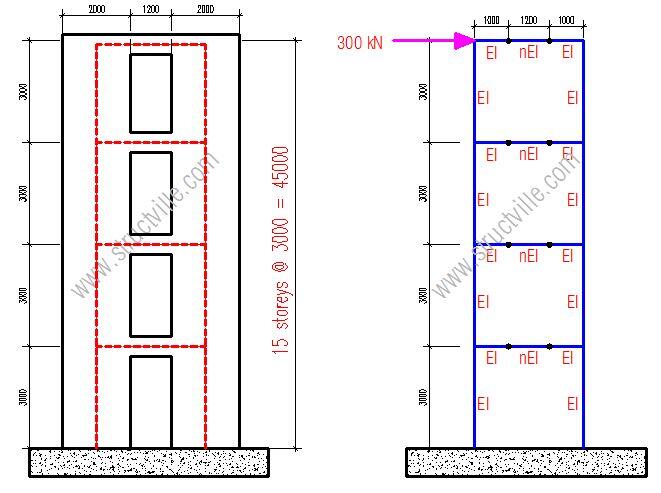

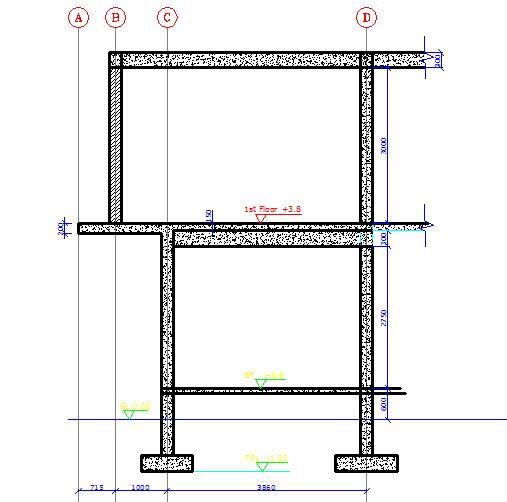

To make this point clearer, let us consider this practical scenario below. The ground floor of a 3-storey commercial development is 4.0 m high, and the details of the column reinforcement are as shown below;

CT1 – Column Type 1 (230 x 230)mm – 2 Nos

Main bars: 4Y16

Links: Y10-200 c/c

CT2 – Column Type 2 (450 x 230)mm – 4 Nos

Main bars: 6Y16

Links: Y10-200 c/c

CT3 – Column Type 3 (600 x 230)mm – 2 Nos

Main bars: 8Y20

Links: Y10-250 c/c

CT4 – Column Type 4 (450 x 450)mm – 1 No

Main bars: 12Y20

Links: Y10-300 c/c

At a lap length of 45ϕ (45 x diameter of bar), the typical bending schedule prepared by the structural engineer for the main bars of the ground floor to first floor columns is as follows:

From the above bending schedule, the quantity of steel to be purchased (per 12 m length) for the main bars are as follows;

Y16: [242.28/(1.579 x 12)] = 12.78 (say 13 lengths of Y16mm)

Y20: [343.51/(2.466 x 12)] = 11.61 (say 12 lengths of Y20mm)

As you can see, these quantities are easily verifiable from the bending schedule and could have possibly been used in the preparation of the bill. It is the exact quantity required as given in the drawing.

However, let us go to site and see how this will possibly play out:

The total quantity of bar mark 01 that will need to be cut by the iron bender/fitter is 32 pieces (kindly verify), and the cut length of each bar is 4795 mm. What this means is that he can only obtain 2 pieces of bar mark 01 from each 12m length of reinforcement, and an offcut of 2410 mm. This offcut cannot be used anywhere in the column, except perhaps it gets useful in the beams or other places. Since 32 pieces of bar mark 01 are required, he will need 16 lengths of Y16 mm against the 13 lengths calculated in the bending schedule. Of course, there will be 16 pieces of 2410 mm as offcut!

In the same way, the total quantity of bar mark 02 that will need to be prepared by the iron bender is 28 pieces, and the cut length of each bar is 4975 mm. This also means that he can only obtain 2 pieces of bar mark 02 from each 12m length of reinforcement, with an offcut of 2050 mm. In effect, he will need 14 lengths of Y20 mm against the 12 lengths calculated in the bending schedule.

If the contractor did not make this consideration before requesting for supply, he will likely make his request twice, to the detriment of extra cost. Therefore, the effects of offcuts should be verified by the contractor before he can place his order for reinforcement. This is usually very common, especially for someone who has not experienced it before.

Thank you for visiting Structville today, and God bless you.

Do you need help in knowing the exact quantity of reinforcement that you will need to complete your project without needing to go to the market twice? We are here to help you with that. When you send your drawings to us, we will assess all reinforcements and bar marks independently, and tell you where all offcuts can be reused. We achieve this by issuing a special bending schedule and cutting scheme that takes into account re-usage of offcuts for foundations, beams, slabs, and columns. We will also issue a cutting sequence to the iron bender such that wastage can be minimised as practically as possible. This can save you a reasonable amount of money for your projects, and we do this for a very low fee that is based on the quantity of offcuts that we saved for you. Try us today by sending an e-mail to info@structville.com