Punching shear is one of the most critical failure modes in flat slabs, characterized by its catastrophic and brittle nature. In existing buildings, there may come a time when there is a need for strengthening flat slabs against punching shear failure.

A flat slab is a type of suspended floor without beams, allowing for direct transfer of loads from the slab to the columns. They are frequently employed in building construction due to their ease of construction (especially in formwork and reinforcement placement), cost efficiency, and ability to accommodate lower floor heights. A flat slab construction, however, experiences significant transverse loads concentrated around the column, which can result in non-ductile, sudden, and brittle punching failure.

Most design codes worldwide have well-established design guidelines to prevent punching shear failure during the design process. Incorporating steel reinforcement, such as stirrups, shear heads, or shear studs, in the high shear zone enhances ductility, a crucial requirement in the design process.

However, there are several factors that can lead to a decrease in the punching shear strength of flat slabs. These include casting concrete with a compressive strength lower than the intended value, incorrectly placing the punching shear reinforcement, and neglecting tension forces caused by shrinkage restraint or temperature changes, which have been shown to reduce the shear strength of the concrete.

Additionally, insufficient punching shear capacity of flat slab structures can be attributed to factors such as changes in usage and loading, new installations, or design and construction errors. Sometimes, this necessitates either upgrading existing structures or replacing them entirely. However, replacing deficient structures is often not a feasible option due to the substantial costs involved. Therefore, repairing and/or strengthening inadequate structures represents a viable solution, offering cost and time savings.

Strengthening is necessary to regain or improve the punching shear strength of the slab in this situation. To enhance the structural integrity, one can employ several methods such as incorporating drop beams, increasing the thickness of the slab near the columns with steel or concrete caps, or introducing punching shear reinforcement.

Techniques for Strengthening Flat Slabs against Punching Shear

To enhance the punching shear capacity of a flat slab-column connection, one can employ methods such as using a thicker slab, a larger column, concrete with higher compressive strength, more flexural reinforcement, or more shear reinforcement. These options can be generally categorised into;

- Shear strengthening,

- flexural strengthening,

- enlargement of the support, and

- post-tensioning systems.

In any project, some techniques for increasing the punching shear capacity of flat slabs are better than others, especially when considering architectural features and cost. Some exclusive methods of strengthening flat slabs against punching shear are discussed below;

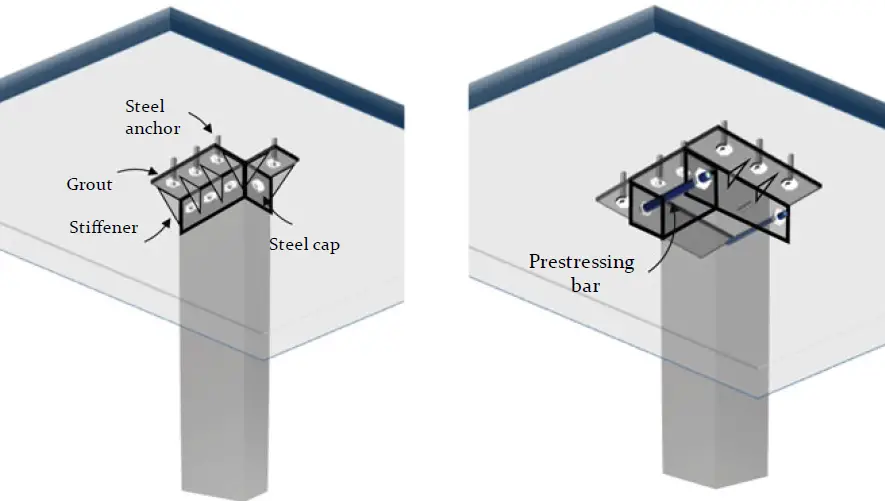

Slab Strengthening by Columns Caps

Steel or concrete caps can be used at the top of columns to shift the critical section of the slab in punching shear away from the column face, thereby increasing the overall punching shear capacity of the slab. A typical steel cap used for slab strengthening is shown in Figure 2.

The steel cap is attached to the column and the slab soffit using steel dowels. Steel stiffeners are used to increase the flexural stiffness of the steel plates attached to the slab. Grout is used to fill the gap between the steel cap and the bottom slab soffit to ensure good contact between the cap and the slab soffit. Strengthening efficiency will be greatly reduced if cracks or small gaps exist between the slab and the cap, as no vertical deformations of the slab are expected in this zone under the effect of gravity loads.

Punching Shear Reinforcement

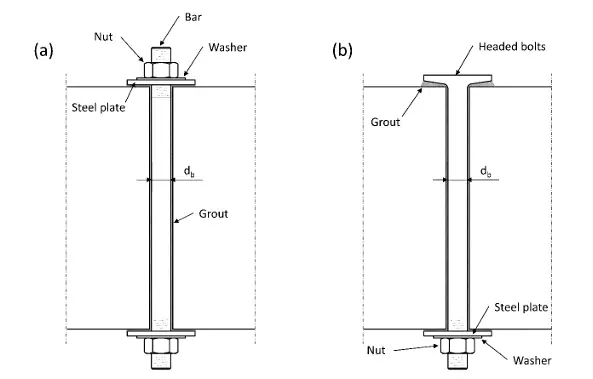

To enhance the overall punching shear strength of the slab, it may be necessary to add steel reinforcement. The main types of shear reinforcement used for enhancing punching shear capacity are;

- anchored bolts with nut, washer and plate

- headed bolts

- bonded bolts

- grids or fans (only for composite materials)

- stirrups (only for composite materials)

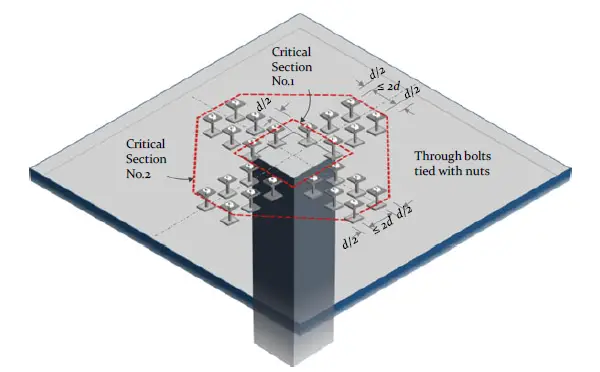

This process usually involves drilling through the slab near the column, where the flexural steel reinforcement is often densely packed. To prevent the need for cutting steel rebars during slab drilling, one can utilize steel detecting equipment to accurately locate the reinforcement.

After identifying the rebars, holes with a diameter bigger than that of the stirrups are drilled. The steel shear bars are then put through these holes and secured to the top and bottom concrete soffits using steel nuts, as depicted in Figure 4. To safeguard the steel bars and prevent corrosion, it is imperative to pump epoxy into the holes.

The quantity of shear bars is established according to the design specifications and the aspect ratio of the columns. The design standard dictates that the entire area of the steel bars at the critical section must be determined.

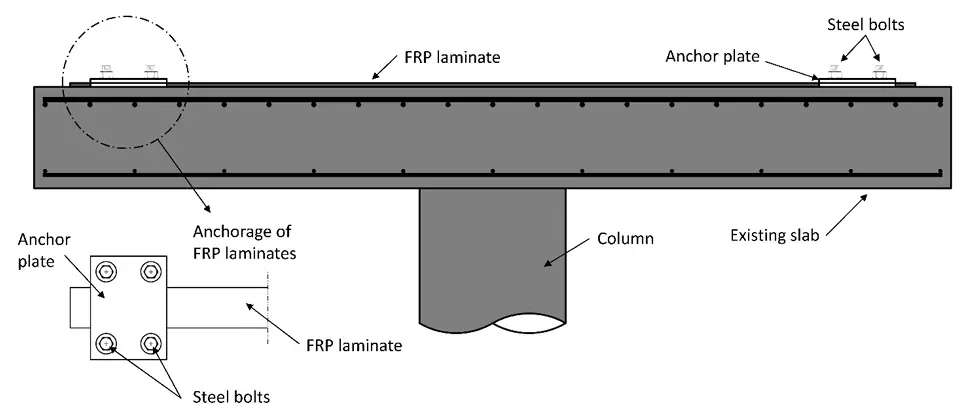

Use of FRP Sheets

Glueing fibre-reinforced polymer (FRP) strips in both perpendicular directions of the slab around the column head can enhance the slab’s flexural capacity. Employing bonded FRP strips in both orthogonal directions as a strengthening technique solely impacts the load-rotation curve, whereas the failure criterion remains relatively unchanged. The load-rotation curve post-strengthening exhibits increased stiffness due to the augmented longitudinal reinforcement.

Generally, this method of flat slab strengthening enhances the punching shear resistance but diminishes the ductility of the connection. The failure becomes more brittle as the maximum rotation after reinforcement is lower than that of the current slab. The efficacy of this strengthening technique is closely tied to the quantity of flexural reinforcement in the existing slab.

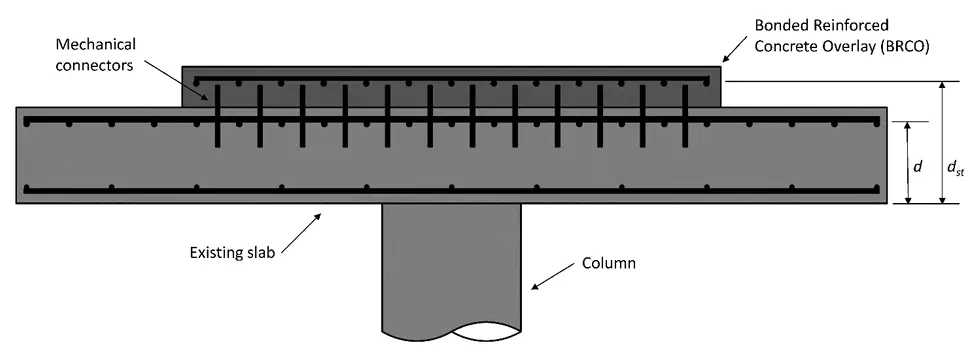

Bonded Reinforced Concrete Overlay

A bonded reinforced concrete overlay (BRCO) may be used if the fibre-reinforced polymer (FRP) strengthening is insufficient to reach the desired punching capacity. The application of a BRCO (Figure 6) may be included in the flexural strengthening techniques, but it actually affects both the failure criteria and the load rotation curve. This technique increases the punching strength by improving the failure criteria curve.

In this method, a reinforced concrete overlay of a specified thickness is placed around the column head of the flat slab. Mechanical shear connectors are used to bond the old and new concrete for maximum load transfer. The disadvantage of this method is its potential to disrupt the architectural features of the building.

Enlargement of the support

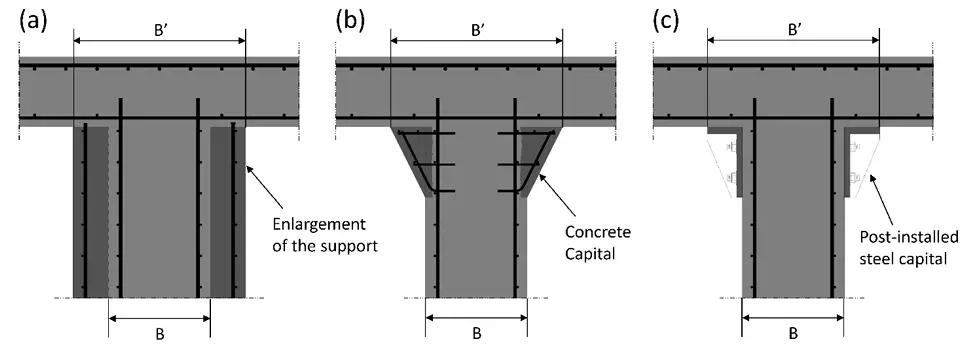

To enhance the punching shear capacity of flat slabs, one might consider enlarging the column, adding a concrete capital, or inserting a steel capital after the initial installation (Figure 7). If the failure does not affect the capital, the latter two solutions can be considered similar to the first one. Moreover, the capital must possess enough rigidity to provide enough support to the slab; otherwise, the effectiveness of the strengthening technique may be compromised.

The expansion of the support impacts both the failure criterion curve and the load rotation curve. Nevertheless, the alteration of the load-rotation curve is solely observed in the vicinity of the horizontal plateau, where the maximum flexural capacity is attained. Due to this characteristic, this particular strengthening approach is less susceptible to the initial rotation compared to other techniques.

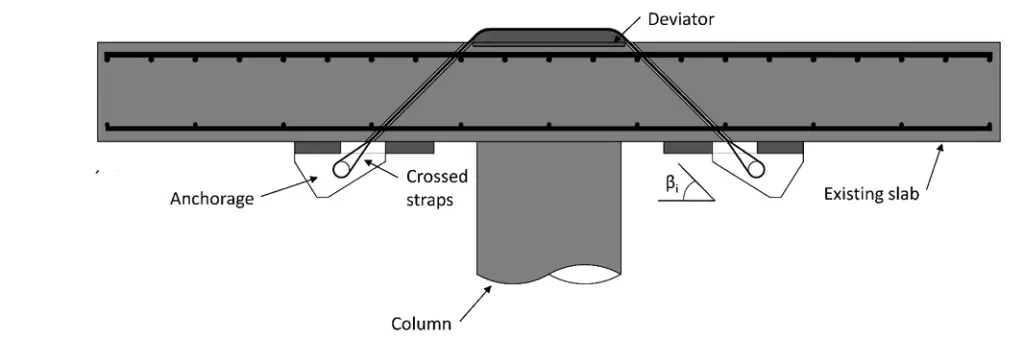

Post-tensioning

Post-tensioning systems can be used to enhance the strength of existing reinforced concrete flat slabs. These strengthening techniques can be divided into two categories: flexural strengthening and shear strengthening. Flexural strengthening typically involves the installation and prestressing of FRP strips on the top surface of the slab. The second method involves the use of inclined steel or FRP straps that are fastened through steel plates or by bonding.

The impacts of prestressing systems can generally be categorized into three main aspects:

- In-plane compressive forces

- deviation forces caused by the inclination of tendons

- bending moments caused by the eccentricity of tendons;

The load rotation curve and the failure criterion curve are both influenced by in-plane forces. The compression field enhances the flexural strength and increases the rigidity of the slab. Moreover, compressive stresses within the same plane increase the strength of interlocking that is supported by the critical shear crack.

Conclusion

In this article, some of the methods of improving the punching shear capacity of reinforced concrete flat slabs were reviewed. The major takeaways are as follows;

Post-installed shear reinforcement has proven to be an effective and reliable method for structural strengthening of flat slabs against punching shear. Numerous studies have successfully determined the optimal quantity and type of shear reinforcement for most structures, preventing punching failure and enabling the slab to achieve its maximum flexural capacity.

However, in some instances, designing shear reinforcement to avert punching failure has not been feasible due to premature concrete strut crushing. The introduction of shear steel bolts can enhance the slab’s deformation capacity by 47.4% and its load-bearing capacity by 15.4%.

Reinforcing a slab with FRP strips for flexural strength indirectly improves its punching resistance by increasing the slab’s overall stiffness. Consequently, the effectiveness of this technique is directly linked to the existing slab’s longitudinal reinforcement ratio (ρ). As ρ increases, the effectiveness of flexural strengthening with FRP strips diminishes.

In a certain study, the use of CFRP sheet as externally bonded flexural reinforcement, in addition to steel reinforcing bars on the tension face of the slab, increased the punching shear capacity and ultimate deflection by about 50 and 30% respectively.

Using a BRCO (bonded reinforced concrete overlay) offers superior outcomes compared to FRP strips. The increased slab depth due to the BRCO improves the failure criterion, enabling the achievement of higher punching strength. However, to prevent premature debonding of the reinforced concrete overlay, the utilization of mechanical connectors is advisable.

Enlarging the support can be accomplished by casting a new concrete capital or installing a steel capital. This strengthening method influences both the failure criterion and the load-rotation curve, but its effectiveness is unaffected by the shear load at the time of strengthening.

With a new support size twice that of the existing support, punching strength increases by 30-50%. The primary factor influencing punching strength after strengthening is the ratio between the critical perimeter after and before strengthening.

Flexural and shear post-tensioning systems are also viable options for strengthening against punching shear. However, flexural post-tensioning systems have encountered issues due to anchorage failures. Conversely, shear prestressing systems demonstrate greater reliability and enable substantial increases in punching capacity. The effectiveness of this technique is time-independent, and results obtained on both unloaded and loaded slabs are expected to be similar. Moreover, shear post-tensioning can reduce slab deflection and crack width under service loads.

Combining various techniques is also a feasible approach. For instance, FRP strips on the slab’s top surface can be coupled with post-installed shear reinforcement, achieving both flexural and shear strengthening. Shear post-tensioning systems can be applied prior to flexural strengthening techniques like FRP or BRCO to minimize initial slab rotation and enhance the efficacy of the strengthening measures.

References

Abdelrahman A. (2023): Strengthening of Concrete Structures – Unified Design Approach, Numerical Examples and Case Studies. Springer Nature