In the construction of steel structures, there is always a need to join steel members for the purpose of continuity. It is not always possible to have the full lengths of members to span the desired length due to production, handling, and transportation issues. As a result, it is very common to bolt or weld two or more steel members, so as to achieve the desired length.

A bolted beam splice connection is a structural joint used in the construction of steel beams. It is designed to connect two or more beams end-to-end to form a longer beam, increasing the span length or overall structural capacity. The design of a bolted beam splice connection involves several considerations to ensure its strength, stability, and reliability.

The design of a bolted beam splice connection involves careful consideration of load transfer, bolted connection details, splice configuration, stiffness requirements, structural analysis, connection detailing, and material properties. By implication, all the anticipated design forces acting at the point of the beam splice must be taken into consideration during the design.

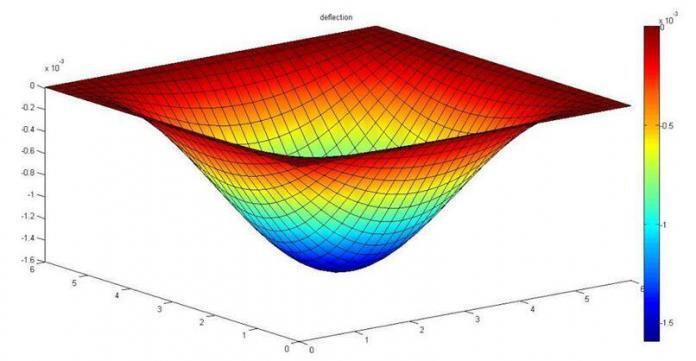

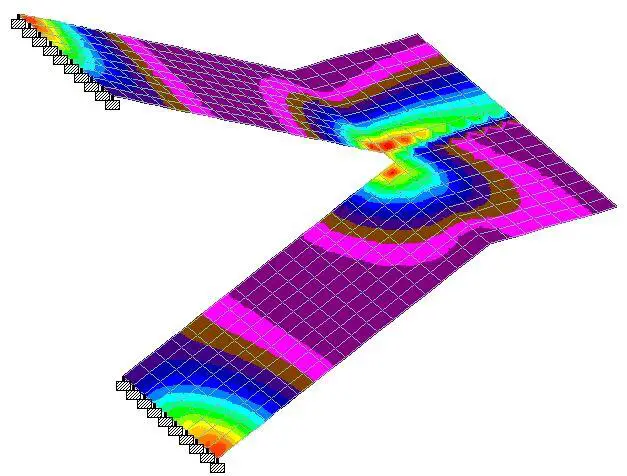

Therefore, the design involves performing structural analysis to determine the forces and moments acting on the connection. This analysis considers the applied loads, beam properties, and connection geometry. Finite element analysis or other advanced analysis methods may be employed to evaluate the connection’s behaviour under different loading conditions.

In this article, we are going to look at a design example of a beam splice connection (beam-to-beam connection using steel plates). This joint should be able to transmit bending, shear, and axial forces.

Design and functions of Bolted Splice Connections

The primary function of a beam splice connection is to transfer the loads between the beams effectively. The connection should be designed to transfer axial forces, shear forces, and bending moments from one beam to another without significant deformation or failure.

The connection typically consists of bolts, washers, and nuts. High-strength bolts are commonly used due to their ability to withstand heavy loads. The number, size, and grade of bolts are determined based on the design requirements and the applied loads.

The configuration of the splice connection depends on the structural requirements and the type of loads being transferred. Common types include full-depth end plate splices, extended end plate splices, and flange plate splices. The choice of splice configuration is influenced by factors such as the beam profile, connection stiffness, and fabrication constraints.

The stiffness of the splice connection plays a crucial role in maintaining the overall structural integrity and load distribution. Adequate stiffness helps to limit deflections and minimize differential movement between the spliced beams. The connection should be designed to ensure that it does not introduce excessive additional stiffness or flexibility to the overall beam system.

Design Example

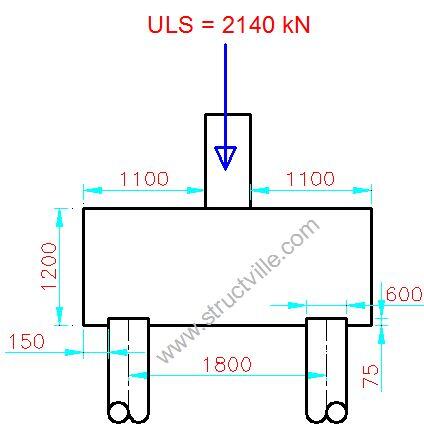

Let us design a bolted beam splice connection for a UB 533 x 210 x 101 kg/m section, subjected to the following ultimate limit state loads;

MEd = 610 kNm

VEd = 215 kN

NEd = 55 kN

At serviceability limit state;

MEd,ser = 445 kNm

VEd,ser = 157 kN

NEd,ser = 41 kN

Properties of UB 533 x 210 x 101

h = 536.7 mm

b = 210 mm

d = 476.5 mm

tw = 10.8 mm

tf = 17.4 mm

r = 12.7 mm

A = 129 cm2

Iy = 61500 cm4

Iz = 2690 cm4

Wel,y = 2290 cm3

Wpl,y = 2610 cm3;

hw = h – 2tf = 476.5 mm

Cover plates

Let us assume 20 mm thick cover plates for the flanges and 15 mm thick plates for the web. The thickness and dimension to be confirmed later in the post.

Bolts

M24 preloaded class 8.8 bolts

Diameter of bolt shank d = 24mm

Diameter of hole d0 = 26mm

Shear area As = 353 mm2

Materials Strength

Beam and cover plates;

fy,b = fy,wp = 275 N/mm2

fu,b = fu,wp = 410 N/mm2

Bolts

Nominal yield strength fyb = 640 N/mm2

Nominal ultimate strength fub = 800 N/mm2

Partial Factors for Resistance (BS EN 1993-1- NA.2.15)

Structural Steel

γm0 = 1.0

γm1 = 1.0

γm2 = 1.1

Parts in connections

γm2 = 1.25 (bolts, welds, plates in bearing)

γm3 = 1.0 (slip resistance at ULS)

γm3,ser = 1.1 (slip resistance as SLS)

Step 1: Internal Forces at Splice

For a splice in flexural member, the parts subject to shear (the web cover plates) must carry, in addition to the shear force and moment due to the eccentricity of the centroids of the bolt groups on each side, the proportion of moment carried by the web, without any shedding to the flanges.

The second moment of area of the web is;

Iw = [(h – 2tf)3tw/12]

Iw = [(476.53 × 10.8)/12] × 10-4 = 9737 cm4

Therefore the web will carry 9737/61500 = 15.8% of the moment in the beam (assuming an elastic stress distribution), while the flange will carry the remaining 84.2%.

The area of the web is;

Aw = 476.5 × 10.8 × 10-2 = 51.462 cm2

Therefore, the web will carry 51.462/129 = 39.8% of the axial force in the beam, while the flange will carry the remaining 60.1%.

Forces at ULS

The force in each flange due to bending is therefore given by;

Ff,M,Ed = 0.842 × [(MEd)/(h – tf)]

Ff,M,Ed = 0.842 × [(610 × 106)/(536.7 – 17.4)] × 10-3 = 989 kN

And the force in each flange due to axial force is given by;

Ff,N,Ed = 0.601 × (55/2) = 16.53 kN

Therefore

Ftf,Ed = 989 – 16.53 = 972.47 kN

Fbf,Ed = 989 + 16.53 = 1005.53 kN

The moment in the web = 0.158 × 610 = 96.38 kNm

The shear force in the web = 215 kN

The axial force in the web = 0.398 × 55 = 21.89 kN

Forces at SLS

The force in each flange due to bending is therefore given by;

Ff,M,Ed = 0.842 × [(MEd,ser)/(h – tf)]

Ff,M,Ed = 0.842 × [(445 × 106)/(536.7 – 17.4)] × 10-3 = 721.53 kN

And the force in each flange due to axial force is given by;

Ff,N,Ed = 0.601 × (41/2) = 12.3205 kN

Therefore

Ftf,Ed = 721.53 – 12.32 = 709.21 kN

Fbf,Ed = 721.53 + 12.32 = 733.85 kN

The moment in the web = 0.158 × 445 = 70.31 kNm

The shear force in the web = 157 kN

The axial force in the web = 0.398 × 41 = 16.318 kN

Choice of Bolt Number and Configuration

Resistances of Bolts

The shear resistance of bolts at ultimate limit state

For M24 bolts in single shear = 132 kN

For M24 bolts in double shear = 265 kN

Flange Splice

For the flanges, the force of 1005.53 kN at ULS can be provided by 8 M24 bolts in single shear.

The full bearing resistance of an M24 bolt in a 20 mm cover plate (without reduction for spacing and edge distance) is;

Fb,max,Rd = (2.5fudt)/γm2

Fb,max,Rd = [(2.5 × 410 × 24 × 20)/1.25] × 10-3 = 393.6 kN

This is much greater than the resistance of the bolt in single shear, and thus the spacings do not need to be such as to maximise the bearing distance. Four lines of 2 bolts at a convenient spacing may be used.

Web Splice

For the web splice, consider one or two lines of 4 bolts on either side of the centreline. The full bearing resistance on the 10.8 mm web is;

Fb,max,Rd = (2.5fudt)/γm2

Fb,max,Rd = [(2.5 × 410 × 24 × 10.8)/1.25] × 10-3 = 212.54 kN

This is less than the resistance in double shear, and will therefore determine the resistance at ULS. To achieve this value, the spacings will need to be;

e1 ≥ 3d0 = 3 × 26 = 78mm

p1 ≥ 15d0/4 = (15 × 26)/4 = 97.5 mm

e2 ≥ 1.5d0 = 1.5 × 26 = 39 mm

p2 ≥ 3d0 = 3 × 26 = 78mm

Initially, try 4 bolts at a vertical spacing of 120mm at a distance of 80mm from the centreline of the splice.

The additional moment due to the eccentricity of the bolt group is;

Madd = 215 × 0.08 = 17.2 kNm

Bolt forces at ULS

Force/bolt due to vertical shear = 215/4 = 53.75 kN

Force/bolt due to axial compression = 21.89/4 = 5.47 kN

Force/bolt due to moment (considering top and bottom bolts only) = (96.38 + 17.2)/0.36 = 315.5 kN

Thus, a single row is adequate.

Considering the second line of bolts at a horizontal pitch of 100mm

Force/bolt due to vertical shear = 215/4 = 53.75 kN

Force/bolt due to axial compression = 21.89/4 = 5.47 kN

Force/bolt due to moment (considering top and bottom bolts only) = (96.38 + 17.2)/0.36 = 315.5 kN

The additional moment due to eccentricity of this bolt group is;

Madd = 215 × (0.08 + 0.1/2) = 27.95 kN.m

The polar moment of inertia of the blot group is given by;

Ibolts = 6 × 1202 + 8 × (100/2)2 = 106400 mm2

The horizontal component of the force on each top and bottom bolt is;

FM,horiz = {[(96.38 + 27.95) × 120]/106400} × 103 = 140.22 kN

The vertical component of the force on each top and bottom bolt is;

FM,vert = {[(96.38 + 27.95) × 50]/106400} × 103 = 58.425 kN

Therefore, the resultant force on the most highly loaded bolt is;

Fv,Ed = sqrt[(53.75 + 58.425)2 + (140.22 + 5.47)2] = 183.87 kN

This is less than the full bearing resistance, and is therefore satisfactory for such a bolt spacing.

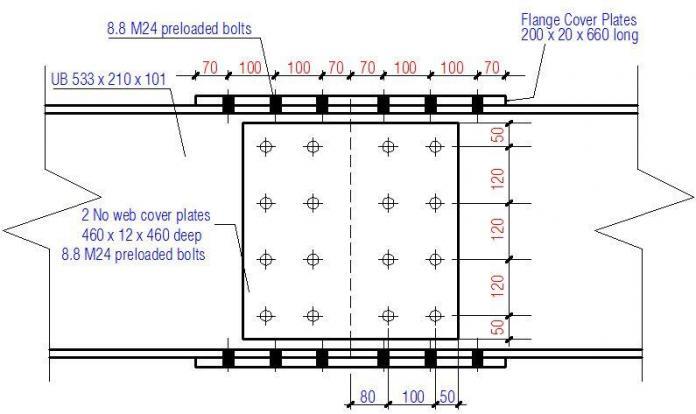

Chosen Joint Configuration

Summary of cover plate dimensions and bolt spacing

Flange cover plates;

Thickness tfp = 20 mm

Length hfp = 660 mm

Width bfp = 200 mm

End distance e1,fp = 70 mm

Edge distance e2,fp = 30 mm

Spacing

In the direction of the force p1,f = 100 mm

Transverse to direction of force p2,f = 120 mm

Across the joint in direction of force p1,f,j = 120 mm

Web cover plates;

Thickness twp = 12 mm

Length hwp = 460 mm

Width bwp = 460 mm

End distance e1,wp = 50 mm

Edge distance e2,wp = 50 mm

Spacing

Vertically p1,w = 120 mm

Horizontally p2,w = 100 mm

Horizontally across the joint p1,w,j = 160 mm

Resistance of flange splices

Resistance of net section

The resistance of a flange cover plate in tension (Nt,fp,Rd) is the lesser of Npl,Rd and Nu,Rd.

Here;

Nu,Rd = (0.9Anet,tpfu,fp)/γM2

Where;

Anet,fp = (bfp – 2d0)tfp = [200 – (2 × 26)] × 20 = 2960 mm

Therefore;

Nu,Rd = [(0.9 × 2960 × 410 )/1.1] × 10-3 = 992.945 kN

Npl,Rd = (Afpfy,fp)/γM0 = [(200 × 20 × 275)/1.0] × 10-3 = 1100 kN

Since 1100 kN > 992.945 KN

Nt,fp,Rd = 992.945 kN

For the flange in tension;

Ftf,Ed = 989 – 16.53 = 972.47 kN

Therefore, the tension resistance of a flange cover plate is adequate.

Block Tearing Resistance;

n1,fp = 3 and n2,fp = 2;

The resistance to block tearing (Nt,Rd,fp) is given by:

Nt,Rd,fp = {(fu,fpAnt,fp)/γm2} + {[Anv,fp(fy,fp/√3)]/γm0}

Where:

Ant,fp = tfp(2e2,fp – d0)

Ant,fp = 20 × [(2 × 40) – 26] = 1080 mm2

Anv,fp = 2tfp[(n1,fp – 1)p1,fp + e1,fp – (n1,fp – 0.5)d0]

Anv,fp = 2 × 20[(3 – 1) × 100 + 70 – (3 – 0.5) × 26] = 8200 mm2

Therefore;

Nt,fp,Rd = {[(410 × 1080)/1.1] + [(8200 × 265/√3)/1.0]} × 10-3 = 1657.127 kN

Resistance of cover plate to compression flange

Local buckling resistance between the bolts need not be considered if:

p1/t ≤ 9ε

ε = sqrt(235/fy,fp) = sqrt(235/265) = 0.94

9ε = 9 × 0.94 = 8.46

Here, the maximum spacing of bolt across the centreline of the splice p1,f,j = 120 mm

p1,f,j/tfp = 120/20 = 6

Since 8.46 > 6, no local buckling verification required.

RESISTANCE OF WEB SPLICE

Resistance of web cover plate in shear;

The gross shear area is given by:

Vwp,g,Rd = (hwptwpfy,wp/1.27γm0√3)

For two web cover plates;

Vwp,g,Rd = 2{[(460 × 12)/1.27] × [275/√3]} × 10-3 = 1380.185 kN

VEd = 215 kN. Therefore, the shear resistance is adequate.

The net shear area is given by:

Vwp,net,Rd = Av,wp,net(fu,wp/√3)/γm2

Av,net = (hwp – 3d0)twp

= (460 – 3 × 26) × 12 = 4584 mm2

For two web cover plates;

Vn,Rd = {2 × [4584 × (410/√3)]/1.1} × 10-3 = 1972.9 kN

Therefore, shear resistance is adequate.

Resistance to block tearing

Vb,Rd = (fu,wpAnt)/γm2 + (fy,wpAnv.Anv)/γm0√3

For a single vertical line of bolts;

Ant = twp(e2 – d0/2)

Ant = 12 × (50 – 26/2) = 444 mm2

Anv = twp – e1 – (n1 – 0,5)d0)

Anv = 12 × [460 – 50 – (3 – 0.5)26] = 4140 mm2

For two web plates

Vb,Rd = 2 × {[(410 × 460)/1.1] + [(275 × 4140)/(√3 × 1.0)]} × 10-3 = 1657.53 kN

VRd = min{1657.53, 1972.9, 1380.185 }

VRd = 1380.185 kN

VEd/VRd = 215/1380.185 = 0.1557 < 1.0

This is ok.

Resistance of beam web

Resistance of net shear area

Vn,w,Rd = [Av,net(fu/√3)]/γm2

Where;

Av,net = Av – 3d0tw

Av = A – 2btf + (tw + 2r)tf but not less than ηhwtw

Av = 12900 – (2 × 210 × 17.4) + (10.8 + 2 × 12.7) × 17.4 = 6221.88 mm2

Av = 6221.88 – (3 × 26 × 10.8) = 5379.48 mm2

Thus;

Vn,w,Rd = {[5379.48 × (410/√3)]/1.1} × 10-3 = 1157.632 kN

This is ok.

Resistance of web cover plate to combined bending, shear, and axial force

Vwp,Rd = 1380.185 kN

Vsub>Ed = 215 kN < 1380.185 kN

Therefore, the effects of shear can be neglected

Awp = 12 × 460 = 5520 mm2

Modulus of the cover plate = (12 × 4602)/6 = 423200 mm3

Nwp,Rd = 12 × 460 × 275 × 10-3 = 1518 kN

Therefore, for two web cover plates

Mc,wp,Rd = [(2 × 423200 × 275)/1.0] × 10-6 = 232.76 kNm

For two web cover plates;

Npl,Rd = 2 × 1518 = 3036 kN

Mwp,Ed = 96.38 + 27.95 = 124.33 kNm

Nwp,Ed = 21.89 kN

Mwp,Ed/Mc,wp,Rd + Nwp,Ed/Nwp,Rd

124.33/232.76 + (21.89/3036) = 0.541 < 1.0

Therefore, the bending resistance of the web cover plates is adequate.

Thank you for visiting Structville today, and God bless.