Cracks in buildings are a common phenomenon that can occur due to various reasons such as foundation settlement, shrinkage, thermal expansion, old age, material failure, excessive load, and structural damage. Sometimes, cracks occur in buildings due to the interaction or combination of the factors highlighted above.

Generally, cracks will occur in masonry and concrete elements if the tensile/compressive stress induced in the element exceeds the strength of the material. In concrete elements, it is widely accepted that it is normal for cracks to occur, however, the design interest lies in the width of the crack, crack spacing, severity, and how it affects the appearance and functionality of the structure.

If left untreated, cracks in buildings can lead to water infiltration, structural weakness, and even collapse. Cracks are indications of distress in a building, however, their location, pattern, and severity can be used to assess their significance. It is, therefore, very important to identify and treat cracks in buildings promptly and effectively.

However, the efficacy of any crack repair methodologies in a distressed building depends on a thorough understanding of the underlying causes and the selection of repair procedures that duly consider these factors. Failure to do so may result in only temporary solutions, whereby the cracks reoccur sometime after treatment.

To achieve durable and sustainable crack repair outcomes, it is important to develop a holistic understanding of the causal factors contributing to the cracks and address them in conjunction with the crack treatment. This multifaceted approach ensures that the root causes of the cracks are effectively mitigated, thereby avoiding the recurrence of the problem and guaranteeing long-term success.

In this article, we will discuss the causes of cracks, types of cracks, and various treatment methods.

Causes of Cracks in Buildings

Internal stresses within building components can induce dimensional changes. When these components are restrained from movement, as is typically the case, cracking in buildings can occur.

Furthermore, internal stresses which can be compressive, tensile, or shear can lead to direct cracks in buildings. Notably, common construction materials like masonry, concrete, and mortar exhibit low tensile and shear strength. Consequently, even relatively minor forces that induce tension or shear within these materials can lead to cracking.

Cracks can occur from various factors, broadly categorized into structural and non-structural causes.

Structural Causes

Structural cracks are more concerning as they indicate potential issues with the building’s foundation or load-bearing elements. Structural cracks can occur on the major structural elements such as beams, columns, slabs and load-bearing walls. They also affect partitions and non-load-bearing walls. Common causes include:

(1) Foundation settlement: Differential settlement of the foundation due to poor soil compaction, expansive soils, or excessive loads can cause cracks in walls, floors, and ceilings. Internal stresses are induced in structural members due to differential settlement. These stresses are induced due to the inherent constraints in the various structural members of the building. When the rigid joints of the structure prevent one part from moving relative to another, stresses are developed, and cracks occur.

Depending on the magnitude of the relative settlement, these stresses are usually in excess of that due to the normal load imposed on the structure, and more often than not, they may not have been accounted for in the design. Therefore, whenever one part of a building settles relative to another, major cracks occur on the building.

(2) Inadequate Design: Inadequate structural design, such as the provision of an inadequate number of reinforcements, inadequate member sizes, excessive deflection, etc. can cause cracks in a building when it is loaded.

(3) Construction flaws: Faulty construction practices, or the use of substandard materials can lead to cracks in a building. This can manifest in the use of weak concrete mixes, sandcrete blocks of inadequate strength, alkali-silica reactions in concrete, reinforcements of inadequate strength, poor compaction of soil, etc. Therefore, poor construction practices can lead to the development of cracks in buildings.

(4) Movement in supporting elements: A well-established scientific principle states that all materials exhibit thermal expansion (expansion upon heating) and contraction (contraction upon cooling). However, the magnitude of this dimensional change varies across different materials and structures due to their unique molecular and other inherent properties.

When constraints are placed on a structural component that impedes its natural thermal movement, internal stresses are generated within the material. These stresses can take the form of tensile or shear forces, potentially leading to cracking. Thermal expansion and contraction of structural elements due to temperature differences can cause cracks, especially at joints.

(5) Overloading: Excessive load placed on floors or roofs beyond their design capacity can lead to cracking. For instance, converting residential buildings to storage houses without proper structural evaluation can lead to cracks or structural failure.

Non-Structural Causes

These cracks are generally less severe and often cosmetic in nature. While non-structural cracks typically do not compromise the structural integrity of a building, they can present aesthetic concerns. These cracks may create the impression of poorly executed construction or impart a sense of instability within the structure.

Furthermore, in certain scenarios, non-structural cracks can allow moisture ingress, potentially leading to the deterioration of interior finishes and increased maintenance costs. Consequently, the implementation of measures to prevent or minimize the occurrence of such cracks is considered essential.

They can be caused by:

(1) Shrinkage of materials: Loss of moisture during concrete curing can lead to cracking. When surface moisture evaporates at a faster rate than it is replenished by bleed water, shrinkage occurs in the upper layer. This shrinkage is hindered by the less-dried concrete below, inducing tensile stresses within the stiffening and relatively weak surface layer. This is known as autogenous shrinkage.

The resulting cracks exhibit varying depths and may manifest in a random, polygonal pattern, or appear roughly parallel to each other. Cracks also occur in concrete due to drying shrinkage. The characteristics of shrinkage cracks can vary based on inherent properties of the building materials. Cracks may exhibit greater width but be spaced farther apart, or conversely, be thin but appear more closely spaced.

(2) Moisture Content fluctuations: Construction materials such as sandcrete, bricks, mortar, or even concrete can undergo expansion and contraction due to moisture variations. These fluctuations in volume due to changes in moisture content can cause cracks in walls, ceilings, and plaster.

(3) Vibration: Vibrations from traffic or construction activity can lead to minor cracks, especially in older buildings.

Classification of Cracks in Buildings

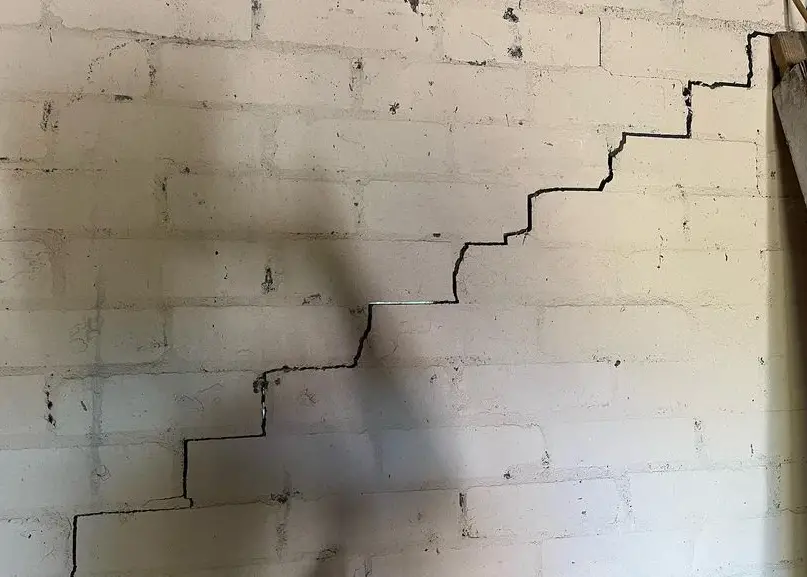

The characteristics of cracks in buildings can vary considerably. The crack width may be uniform throughout the crack, or it may show a gradual increase from one end to the other. Crack patterns can be straight, jagged, stepped, map-like, or random. Additionally, their orientation can be vertical, horizontal, or diagonal. The depth of cracks may range from solely affecting the surface layer to extending through multiple material layers.

The severity of a crack is determined by its width, depth, location, and whether it’s static (inactive) or moving (active). Cracks are active when the causal factor is still taking place. By implication, such cracks will likely reoccur when treated. An active crack may continue to affect other members or areas of the building, or the existing cracks will continue to increase in width and severity. An example of this is a crack that is occurring as a result of ongoing consolidation settlement of the foundation. However, in inactive cracks, the cause of the settlement has been taken care of, and the crack is now static.

However, here is a general classification system for cracks occurring in a building:

Hairline cracks: These are very thin cracks, typically less than 1/24 inch (1 mm) wide. They are often caused by shrinkage or minor settling and may require cosmetic repair. Also, when the joint between masonry infill panels and reinforced concrete columns is not properly treated, hairline cracks may form on the joint after plastering.

Stress cracks: These are slightly wider than hairline cracks, ranging from 1/24 inch (1.5 mm) to 1/5 inch (5 mm). They may indicate movement in the structure and warrant further investigation by a structural engineer. In reinforced concrete beams, flexural cracks will likely occur at the tension zone of the point of maximum bending moment. Shear cracks are usually diagonal cracks that will occur near the supports.

Variable or random cracks on masonry walls may indicate a myriad of stresses acting on the wall. This may be a result of a deflecting beam or slab bearing on a non-load-bearing masonry wall. Masonry walls will also crack when it is supported by members undergoing deflection.

Wide cracks: Cracks exceeding 1/5 inch (5 mm) in width cause concern and require immediate professional evaluation. They could signify significant structural issues. When cracks in masonry walls are diagonal or stepped, the reason may be differential settlement of the foundation. Vertical cracks in masonry walls may also indicate a settling foundation.

Steps in the Remediation of Cracks in Buildings

This section outlines a structured approach to concrete and masonry crack repair, ensuring a comprehensive evaluation, accurate diagnosis, and effective treatment approach.

(1) Evaluation Phase

The initial stage involves a thorough assessment of the building’s condition. This may encompass:

- A careful review of design drawings and structural calculations (where available).

- A site visit and close examination of the building and the areas in distress (masonry and structural members). This may include testing of samples using the non-destructive method.

- Examination of the foundations, soil type, and drainage conditions of the building substructure.

Upon completion of this evaluation, the team will possess a comprehensive understanding of the building’s condition and the underlying causes of the cracks.

(2) Identification of the Causative Factor(s)

Following the evaluation stage, a meticulous assessment is required between the observed conditions of the building, foundation, and test results to give a clear indication of the mechanism responsible for the cracks. As cracks can often occur due to multiple factors, identifying the root cause is important before recommending appropriate solutions.

(3) Repair Method Selection

Once the cause(s) of the cracks have been definitively identified, the most suitable repair method and materials can be strategically chosen.

(4) Plan and Specification Development

The next step entails the preparation of detailed plans for treating the critical elements and establishing precise specifications for the repair materials. Due to potential unforeseen circumstances arising during the repair process, these plans should maintain a degree of flexibility.

(5) Repair Implementation

The success of the repair hinges upon a strict adherence to the established plans and specifications. This level of precision should surpass that employed in new building construction. The evaluation and design work should be undertaken by a qualified structural engineer with a keen eye for detail.

Treatment Methods for Different Cracks

The appropriate treatment for a crack depends on its cause and severity. The primary objectives of concrete crack repair can be summarized as follows:

- Enhancement of Structural Capacity: This includes restoring or increasing the flexural and tensile strength of the building element.

- Improvement of Stiffness: Repair should aim to regain or elevate the rigidity of the distressed element.

- Restoration of Functionality: The repair process should ensure the building element can effectively perform its intended function.

- Waterproofing and Infiltration Mitigation: Cracks should be sealed to prevent water ingress and potential damage.

- Aesthetic Restoration: The repair should improve the visual appeal of the building surface.

- Durability Enhancement: The repair should promote the long-term serviceability of the building.

- Corrosion Protection for Reinforcement: Cracks should be addressed to prevent a corrosive environment from developing around steel reinforcement within the concrete.

Here’s an overview of common repair methods:

Crack Injection

Epoxy, polyurethane resins, or concrete grouts are injected into the crack to fill it, stabilize the surrounding area, and prevent water infiltration. This crack repair method typically involves a three-step process:

- Installation of Entry and Venting Ports: These ports are strategically placed at frequent intervals along the length of the crack to facilitate material injection and air release.

- Sealing of Exposed Crack Surfaces: The crack surface on all exposed areas is meticulously sealed to prevent leakage during the injection process.

- Pressurized Epoxy Injection: Epoxy resin is injected under pressure into the crack through the installed ports.

Epoxy injection has proven to be a successful technique for repairing cracks in various concrete structures, including buildings, bridges, dams, and others.

Crack Stitching

Crack stitching is a near-surface reinforcement (NSR) technique employed to introduce additional tensile strength perpendicular to the crack plane. This method involves creating a precise slot across the crack using a saw-cutting technique. The slot is then meticulously cleaned to ensure optimal bonding. U-shaped metal staples, reinforcements, or fibre-reinforced polymer bars are embedded across the crack and tightened to pull the separated sections together.

Subsequently, an epoxy resin is typically applied within the slot. This resin serves a dual purpose: acting as a strong bonding agent between the existing concrete and the reinforcement and providing a protective barrier for the bar that will be subsequently placed within the slot. This method is suitable for wider cracks in masonry walls.

Grouting

For cracks in foundations or concrete slabs, a cementitious grout is pumped under pressure to fill voids and strengthen the affected area. The grouting procedure entails the following sequential steps:

- Surface Preparation: The concrete surrounding the crack is cleaned to remove any debris or contaminants that could hinder adhesion.

- Grout Nipple Installation: Pre-formed injection points (grout nipples) are strategically installed at predetermined intervals along the crack path. These nipples create a watertight connection with the injection equipment.

- Crack Sealing: The portion of the crack between the installed nipples is effectively sealed using cement paint, sealant, or grout. This sealing process prevents leakage during subsequent grouting.

- Crack Flushing: The entire crack is thoroughly flushed with water to remove any remaining particles and to verify the integrity of the applied crack seal.

- Crack Grouting: Once the crack is clean and the seal is verified, the entire crack is filled with a grout mixture. The specific grout composition, consisting of cement and water or cement, sand, and water, is chosen based on the width of the crack being addressed.

Surface Repairs and Sealing of Cracks

In scenarios where structural integrity is not compromised and only cosmetic repair is required, surface repairs, routing and sealing of cracks can be a suitable approach. This method involves widening the exposed face of the crack to a predetermined depth and subsequently filling and sealing it with an appropriate joint sealant. Compared to procedures like epoxy injection, which require specialized training, routing and sealing is a relatively straightforward technique and is commonly employed for crack treatment.

The selection of the sealant material is flexible, with options including epoxies, urethanes, silicones, polysulfides, asphaltic materials, or polymer mortars. Notably, the use of cement grouts should be avoided due to their high susceptibility to cracking themselves. Hairline cracks or superficial cracks can be repaired with patching materials, sealants, or caulk to improve aesthetics and prevent moisture intrusion. These methods may not fully repair cracks but rather hide or obscure the cracks.

Structural reinforcement

In severe cases, additional structural elements like beams, columns, or piers may be installed to reinforce the weakened area and improve load-bearing capacity.

Preventive Measures: Proactive Steps to Minimize Cracking

Proper foundation design and construction: A well-designed foundation that considers soil conditions and building loads is important to prevent settlement cracks. Proactive steps must be taken during the construction to ensure that proper compaction of trenches and fills is done.

Furthermore, the foundation must be adequately drained. If the soil is expansive or susceptible to differential settlement, the foundation should be designed to accommodate or mitigate against such effects.

Use of high-quality materials: Selecting materials that meet building code requirements and are appropriate for the climate helps minimize shrinkage and movement-related cracks.

Expansion and contraction joints: Incorporating strategically placed expansion joints in buildings, walls, slabs, and roofs allows for natural movement and reduces stress on the structure.

Moisture control: Proper drainage systems and waterproofing membranes prevent moisture-induced cracks in walls and foundations.

Regular maintenance: Regularly inspecting the building for cracks and addressing them promptly helps prevent minor issues from escalating into major problems.

Conclusion

Treatment of cracks in buildings is a critical task that requires a thorough understanding of the causes and types of cracks, as well as the various treatment methods. By understanding the causes and treatments for cracks in buildings, property owners can ensure timely repairs and maintain the structural integrity and safety of their structures.

By following the step-by-step treatment process outlined in this article, building owners and professionals can effectively treat cracks and prevent further damage to the building. Remember, consulting a structural engineer for professional assessment and guidance is always recommended, especially for concerning cracks.