House extensions have recently turned out to be one of the alternatives in demand among those homeowners who want to add space to their homes without needing to relocate. For a growing family that needs extended space, an office, or you simply want to add value to your house, a well-designed extension will be both functional and economical.

House extensions can vary, and in this article, we go further into the world of house extensions, focusing on single-story ones. We look into the main issues, such as the types of extensions, their significance, and important points that will help you through the decision-making process.

What is a Single-Storey Extension?

A single-story extension is a practical means of extending your home by adding space horizontally to the ground floor. Unlike multi-story extensions, which go upwards, single-story ones extend outward, joining quite unobtrusively with the main structure.

It may serve any purpose that fits: a large kitchen, a spacious living room, a new bedroom, or even a home office; it’s a way of extending space without changing the structure of a house at exorbitant costs. Single-story extensions are flexible, serving both functional and aesthetic purposes, thus being one of the most popular ways to improve one’s home.

Benefits of Building a Single-Storey Extension

A single-story extension has a lot of important benefits for improving functionality, value, and comfort in your home. Here are some of these benefits:

Increased Space

The first apparent benefit is the extra space it provides to extend the living areas or include additional bedrooms, even a home office; this is one of the ways homeowners can create the space they need for their needs, enhancing the flow of the house.

Increased Property Value

A well-planned extension can increase the market value of your house by quite a significant amount. Additional square footage is a big plus for potential buyers, especially in those areas where larger properties are in high demand. With a smart extension, you could see a very good return on investment upon resale.

Cost-Effective Solution

It may well be considerably less expensive than buying a bigger house. You will also avoid all the real-life moving costs, which include stamp duty and legal fees, aside from the disruption to move. You could thus stay in the home you love with an extension but achieve what you want in it for more space.

Personalization

Arguably, this is the best thing about building an extension, given that you can tailor it to suit your needs. You can design it in whatever way suits your lifestyle: a home gym, an enlarged kitchen, or a quiet retreat. The result is a space that feels very personal.

Smarter Lifestyle and Functionality

The single-story extension can bring a better quality of life, comfort, and enjoyment of all the simple tasks. You may add an extended kitchen for family get-togethers, a children’s playroom, or an additional bathroom for convenience. The extra space will also contribute to the social get-togethers, providing enough room for family and guests.

Types of Single-Storey Extensions

There are many styles of single-story extensions, with various purposes and to suit various budgets. Here’s a breakdown of the most popular varieties:

Rear Extensions

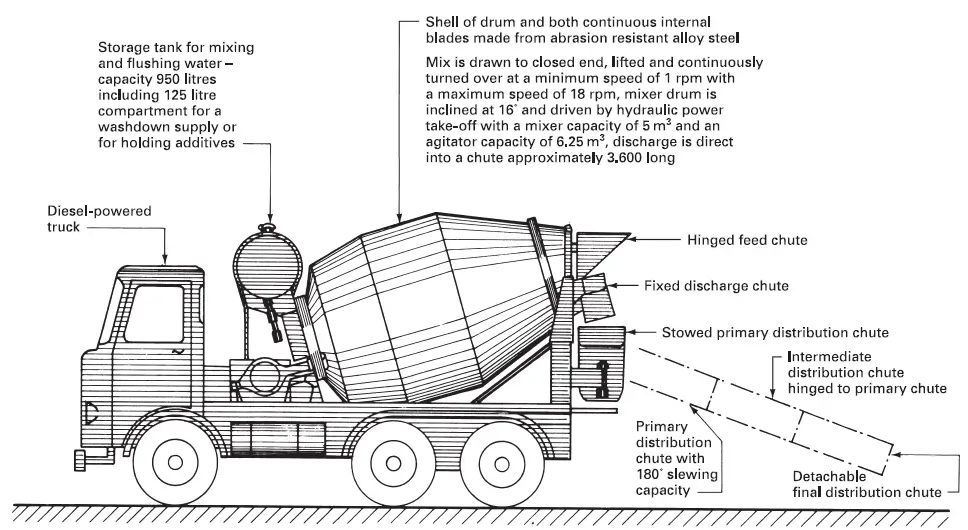

They are built at the back of the house and are ideal for spacious open-plan living areas. Most suited to extend family areas either in the kitchen or the lounge, depending on size, design, and materials, their price ranges start at £ 25,000 – £ 40,000 for an extension.

Side Extensions

The side extension utilizes the alleys or wastes on the side of the house, thus being quite economical. These are a bit narrower than rear extensions but also create space worth having. Prices usually start from £15,000 to £25,000, which is very popular for small plot maximization.

Orangery Extensions

Orangeries capture the sense of a traditional extension with the light, airy feel of a conservatory. They typically feature a combination of solid walls and large windows, although they have a central glazed roof. Great for creating a bright, versatile space such as a sun room or dining area, orangeries will generally cost from £20,000 to £50,000 depending on size and materials.

Wraparound Extensions

Wraparound designs and extensions at the rear and side are the most space-gaining and flexible designs. They are ideal for restructuring the shape of your house, but because of their complexity, they can be more costly, ranging in price from £40,000 – £100,000

Kitchen Extensions

Undoubtedly, kitchen extensions are the most popular methods to extend space for cooking and dining. The price is certainly a variable depending on the size, the fittings, and the materials involved, but an approximate estimate would be around £30,000. Such extensions also bring function and added value to your homes.

Key Considerations Before Building

Extending a property is a great project, but it requires much planning and foresight to succeed. Here are the key factors to consider before starting:

Planning Permission

While most single-story extensions come under Permitted Development Rights, checking with your local planning authority may be necessary. Regulations can vary, and if your extension exceeds specific size or height limits, you may have to take formal planning permission. Researching such regulations early will save legal problems that could cause delays in the project and keep your project aligned with the local rules without any hiccups.

Budgeting

A detailed budget is vital for controlling costs and avoiding overspending. Include construction expenses, design and architectural fees, planning permissions, utilities, and fittings. Allocate contingency funds to address unforeseen costs, which often arise during construction. A clear financial plan ensures you’re prepared for all aspects of the project and reduces the risk of running out of funds midway through. Proper budgeting creates a solid financial foundation for success.

Design and Layout

The work of an architect or a designer will bring into being a functional and aesthetically pleasing space. A good design will consider how the extension will merge with your existing home, maximize natural light, and provide practical access points. Adapt the layout to your lifestyle, considering your present needs and future changes. A smart design can go a long way in improving your home’s comfort, usability, and value.

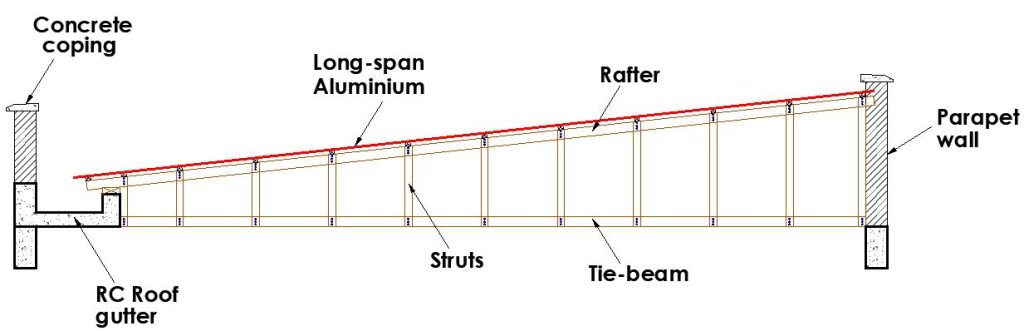

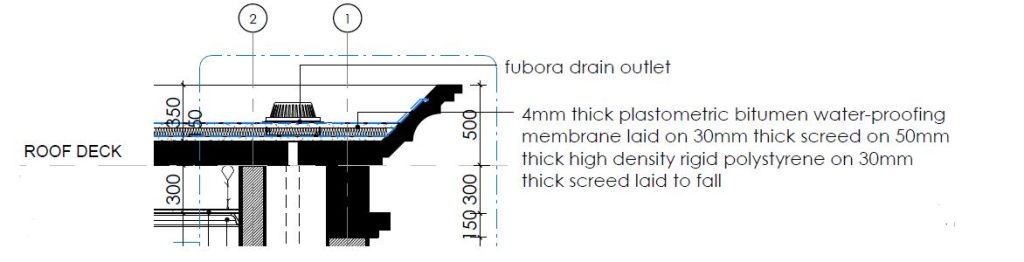

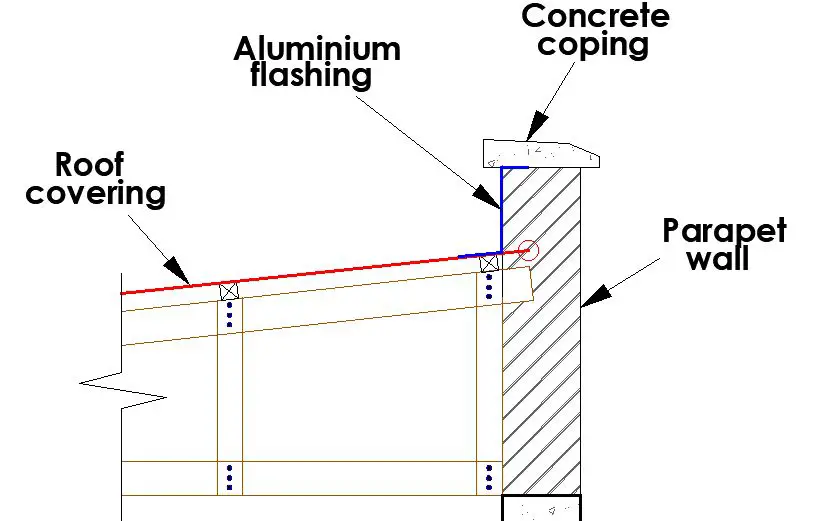

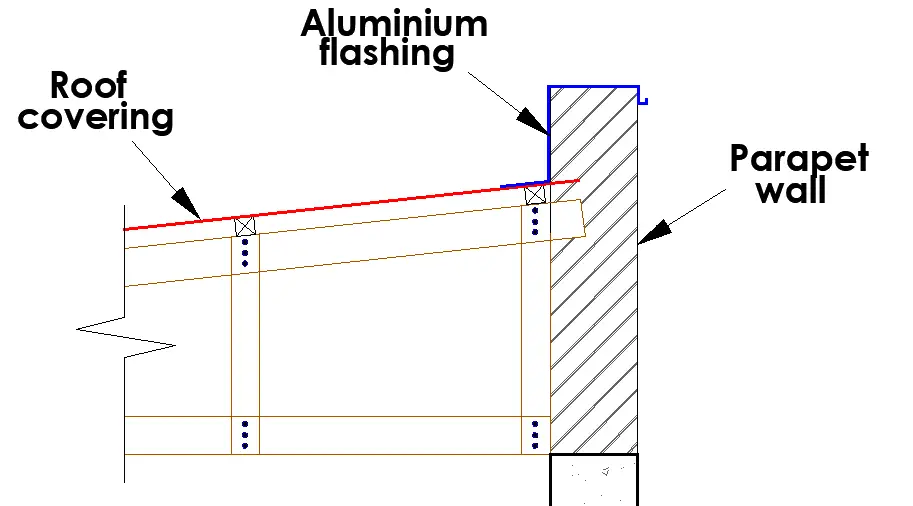

Building Regulations

Following the building regulations concerning the building’s structure, energy efficiency, and safety is important. The set rules involve fire precautions, ventilation, and thermal performance. You may involve a qualified building inspector early enough to help you get smooth approvals and guide you through what precisely you need to do. Meeting these standards will ensure a safe living space, avoiding potential fines or rebuilding work.

Choosing Contractors

The success of the project lies in choosing good and reliable contractors. Find builders with experience working with extensions; check their qualifications and previous jobs. Get several quotes to ensure you’ve got the best one, and ask references to check quality. Clear communication and a properly written contract displaying timelines, costs, and responsibilities will avoid confusion. Indeed, a good contractor will create no hassle and carry out the work per your expectations.

Do You Need an Architect?

Although not needed by UK law, an architect for a single-story extension is often a worthy investment. The expertise an architect can offer will help ensure your design complies with the relevant building regulations and maximizes space, while their experience will enhance functionality and aesthetics. Additionally, architects can assist with planning permission applications and liaise with contractors, streamlining the overall process.

While their fees typically range from 8% to 15% of the total project cost, their ability to identify cost-effective solutions and add value to your home may offset this expense. The complexity of your project, budget, and confidence in overseeing the design and construction process are major factors in whether an architect is needed.

Choosing the Right Architect for Your Project

The selection of the perfect architect is highly crucial to realizing your dreams. A deliberate choice ensures the project meets all your expectations by virtue of the budget and timelines. Here is a step-by-step guide that will help in choosing the perfect architect for you:

Research and Compare

First, research architects in your area, preferably local professionals who know the community’s zoning laws, climate, and aesthetic trends. Get recommendations from friends, family, or online reviews. Take a look at their portfolios to ensure their style and expertise fit your project’s needs.

Focus on Local Expertise

Working with a local architect often means smoother communication, easier site visits, and deep knowledge of the region’s construction requirements. Conclusively, this saves time and reduces the cost of finding more practical, innovative design solutions that best fit the local context.

Get the Best Quote

Before building a single extension, it’ll be important to start by requesting detailed quotes from multiple architects to ensure you’re getting competitive rates. Be clear about your budget and expectations from the start. While cost is a factor, prioritize reliability, creativity, and experience to balance affordability and quality.

Check Credentials and References

Check his licensure and credentials in your state, plus his professional associations. Then, call his references to discuss projects similar to yours; inquire about his communication style, whether he was timely, and how he satisfied their needs.

Schedule a Consultation

Meet with potential architects to discuss project goals, budgets, and ideas. Observe their listening skills, what questions they will ask, and the ideas they propose. A successful collaboration is fundamentally based on a good working relationship.

Tips to Ensure a Smooth House Extension

Extending your home can be that great opportunity to create your space while offering value to the property. Guarantee success with the following workable tips:

Plan Ahead

Invest time in detailed planning before breaking ground. Clear designs, budgets, and timelines help minimize delays and unexpected costs. Consider the permits and approvals necessary to avoid legal or regulatory problems.

Maximize Natural Light

A bright, airy space increases comfort and aesthetics. In themselves, design elements like skylights, large windows, or glass doors can allow natural light into the room and provide a link with the outdoors.

Future-Proof Your Design

Consider how it will pay you back in the coming years with accessible layouts, flexible space, and the use of materials that add to resale value or can be adapted to changing needs.

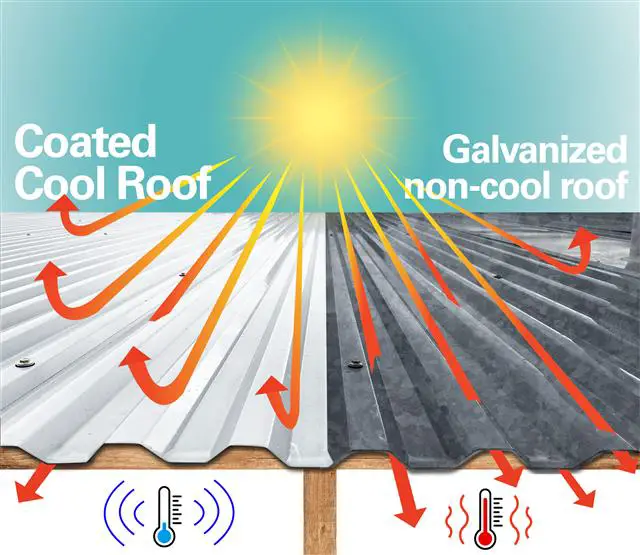

Make It Energy Efficient

Consider energy-efficient solutions such as good insulation, double- or triple-glazed windows, and renewable materials; this reduces utility bills and lessens your environmental footprint. The end effect is that your extension is more environmentally friendly and economical.

Stay Actively Involved

Keep in close contact with your architect, contractor, and project team. You can ensure the project remains on schedule and meets your expectations by promptly staying informed and addressing issues. With careful planning and attention to detail, your extension project has the potential to turn your current house into the perfect fit for your lifestyle and future needs.

Wrapping Up

Adding a single-story extension to your residence has been considered one of the most practical and satisfying ways to increase functionality and market value. Carefully weighing your options, the type of extension, budgeting for materials and labour, and awareness of the rules and regulations with regard to permissions all give homeowners informed choices to suit their needs and financial objectives.

The research and communication with more experienced local builders can be the difference between a smooth, efficient process and a frustrating one. You will have the opportunity to turn your vision into a reality, a place that complements your home and your lifestyle, with the help of trusted professionals.